A twin-shaft strip mill capable of controlling feed

A pulverizer and bar-shaped technology, applied in the field of double-shaft bar-shaped pulverizers, can solve the problems of splashing and affect the pulverization efficiency of pipes, and achieve the effect of improving pulverization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

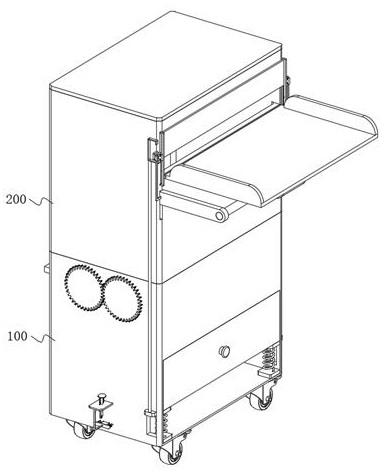

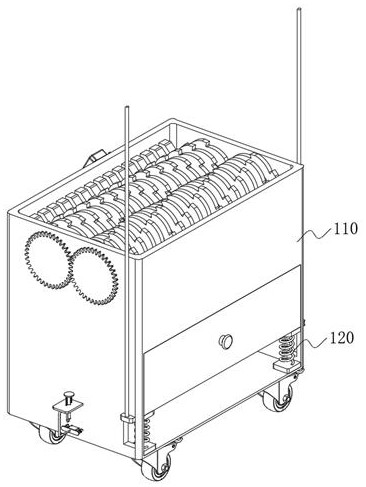

[0049] see Figure 1-Figure 6 As shown, there is provided a twin-shaft strip mill capable of controlling feeding, including a crushing device 100 and a feeding device 200 arranged above the crushing device 100, and the crushing device 100 includes at least:

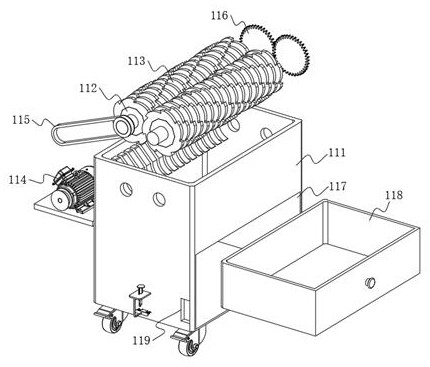

[0050] The crushing assembly 110, the crushing assembly 110 includes a lower casing 111, the top of the crushing assembly 110 is provided with a perforation, the inner wall on both sides of the lower casing 111 is rotatably connected with a rotating roller 112, and the outer wall of the rotating roller 112 is provided with a crushing knife 113 A first motor 114 is installed on one side of the lower housing 111, the output shaft of the first motor 114 is connected with one end of one of the rollers 112 through a belt 115, and the other ends of the two rollers 112 are provided with a gear plate 116 , the two gear discs 116 are meshed, an opening 117 is opened on one side of the lower casing 111, a collecting drawer 118 is a...

Embodiment 2

[0056] In order to prevent the pipe material from being inconvenient to be inserted from the feed port 212 caused by the slow downward movement of the baffle plate 214, the following improvements are made on the basis of Example 1:

[0057] see Figure 7-Figure 8 As shown, wherein, both sides of the baffle plate 214 are fixedly connected with a fixed block 220, the side wall of the fixed block 220 is provided with a first insert 221, the first insert 221 passes through the fixed block 220 and is slidably connected with it, the first insert A connecting spring 222 is arranged between one end of the block 221 and the side wall of the fixed block 220, and one end of the fixed block 220 is in an inclined structure, and the inclined surface of one end of the fixed block 220 faces upwards, so that the first inserting block 221 can be quickly separated from the inserting plate 224 , the bottom inner wall of the mounting rod 213 is provided with a support spring 223, one end of the su...

Embodiment 3

[0061] In order to prevent the baffle plate 214 from being automatically opened when the collection drawer 118 is taken out, the following improvements are made on the basis of Embodiment 1:

[0062] see Figure 9 As shown, wherein, the side wall of the lower casing 111 is provided with a second plug 240, one end of the second plug 240 passes through the lower casing 111 and is slidably connected with it, one end of the second plug 240 is in an inclined structure, the second The inclined surface of one end of the second plug 240 faces upward, and a return spring 241 is arranged between the other end of the second plug 240 and the side wall of the lower housing 111 , and the side wall of the bottom plate 122 is provided with a socket for inserting the return spring 241 . Slot 126, when base plate 122 moves down, because one end of second inserting block 240 is inclined, base plate 122 moves down and pushes second inserting block 240 away, when slot 126 is positioned at the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com