Efficient metal welding equipment

A metal welding and high-efficiency technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of consuming users' time and energy, affecting the use of operators, physical hazards, etc., to achieve the effect of increasing the optionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

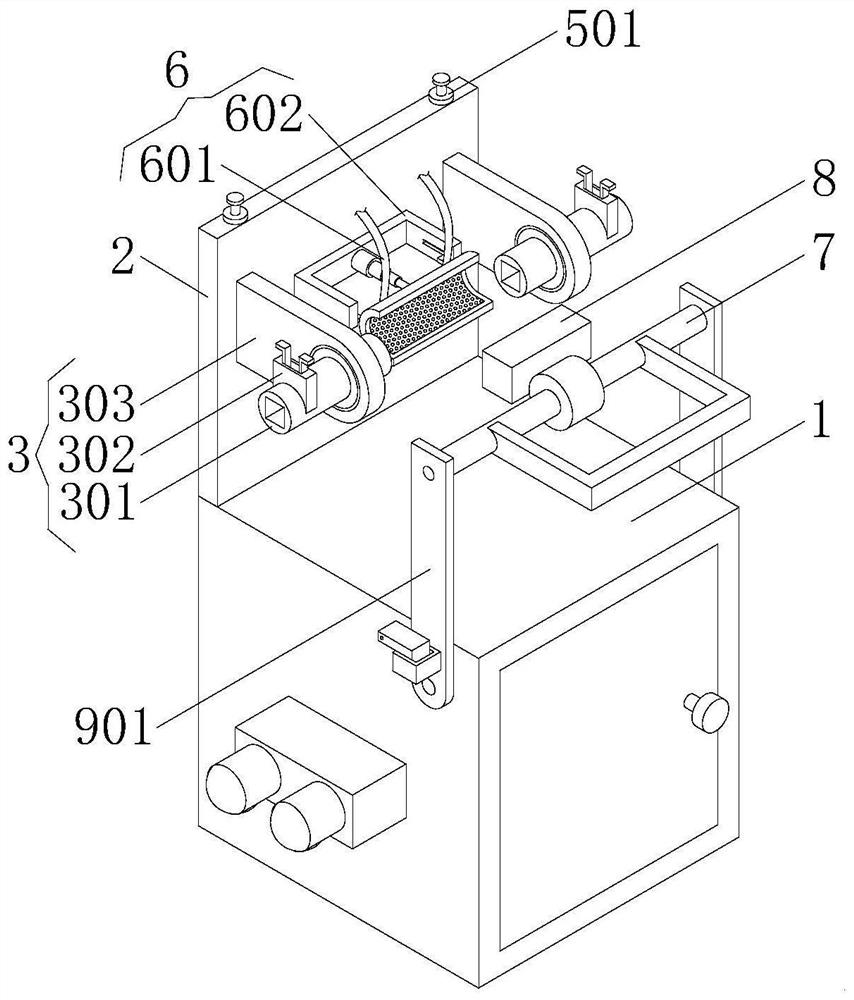

[0048] In order to further and better explain the above embodiments, the present invention also provides an embodiment, a welding method for efficient metal welding equipment, comprising the following steps:

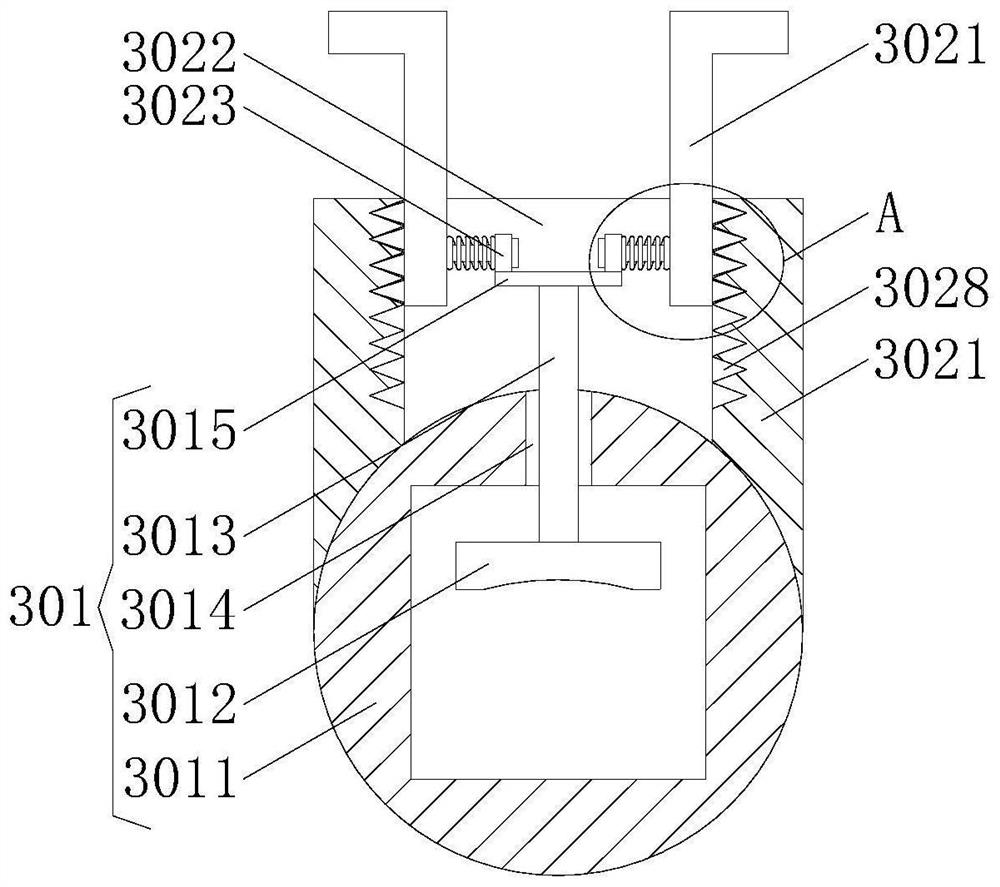

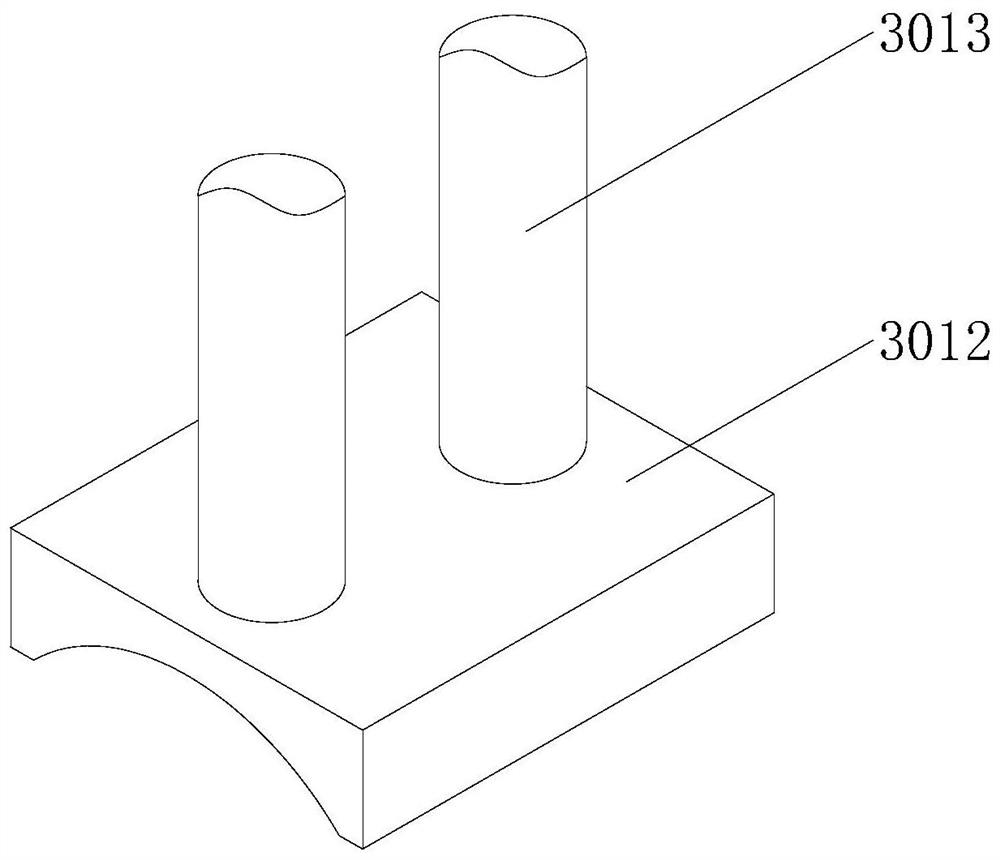

[0049] Step 1: the metal to be welded is inserted into the inside of the clamping assembly 301, and then the clamping effect of the clamping assembly 301 is adjusted by the fixing assembly 302;

[0050] Step 2: After the position of the metal to be welded is fixed, the position of the welding head body 8 is adjusted through the adjustment component 9, and after the adjustment is completed and fixed, the metal is welded through the welding head body 8;

[0051]Step 3: Adjust the position of the absorption component 601 by moving the component 602 during the welding process, the control system 10 will control the absorption component 601 through the central control module 11, and the absorption component 601 will absorb the harmful gas generated during the welding process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com