Automatic measuring and abrasion cutting device for display production and manufacturing

An automatic measurement and display technology, applied in grinding drives, manufacturing tools, grinding machines, etc., can solve the problems of lack of clamping and positioning structure of conveyor belt, unfavorable workpiece processing, workpiece die-cutting, polishing shaking or jittering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

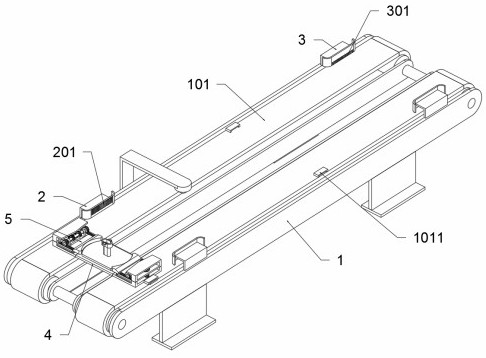

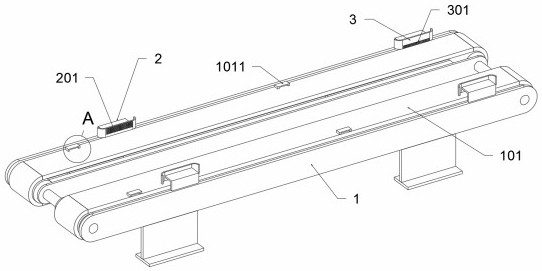

[0036] as attached figure 1 to attach Figure 10 Shown:

[0037] The present invention provides an automatic measuring and grinding device for the production and manufacture of displays, comprising a transmission frame 1, the left end of the frame body of the transmission frame 1 is fixedly connected with two fastening end frames 2, and the two fastening end frames 2 are respectively fixed Connected to the frame bodies on both sides of the transmission frame 1, the fastening end frame 2 includes a fastening rack 201, the fastening rack 201 is set on the inner surface of the fastening end frame 2, and the fastening rack 201 is located on the The upper part of the inner surface of the fastening end frame 2; the fastening end frame 2 of this structure is as figure 2 As shown; the translation positioning processing table 4 is movably connected above the transmission frame 1; the top tension frame 5 is provided with two places, and the two top tension frames 5 are respectively s...

Embodiment 2

[0045] Embodiment 2: Based on the automatic measuring and grinding device for display manufacturing provided in the first embodiment, after the device clamps the workpiece, it realizes positioning and unloading. In order to eliminate the conflict between the clamping drive and the sending drive, combine figure 2 , the automatic measuring and grinding device for display production and manufacturing also includes: two unloading frames 3 are provided, the two unloading frames 3 are fixedly connected above the right end of the transmission frame 1, and the two unloading frames 3 They are respectively fixedly connected to the front side frame and the rear side frame body of the transmission frame 1. The loosening rack 3 includes a loosening rack 301, and the loosening rack 301 is set on the inner surface of the loosening rack 3, and the loosening rack 301 is located at the lower half of the inner surface of the unloading frame 3; the unloading frame 3 of this structure is as fig...

Embodiment 3

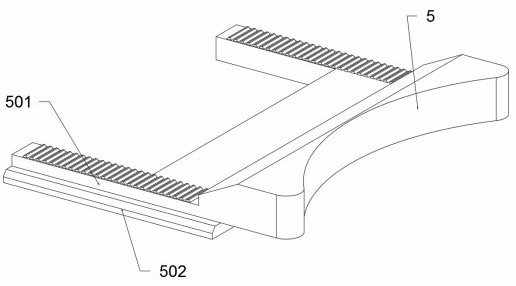

[0046] Embodiment 3: Based on the automatic measuring and grinding device for the production and manufacture of displays provided in the first embodiment, in order to facilitate the clamping of the clamping frame 5, the clamping frame 5 is set as an arc structure, which can better Clamp the display base in disc structure.

[0047] When in use: first, during the operation of the transmission frame 1, the display support is placed on the translation positioning processing table 4. When the translation positioning processing table 4 is running, it drives the translation positioning processing table 4 to move to the right. When the translation positioning processing table 4 When moving to the position of the fastening end frame 2, the fastening gear 403 meshes with the fastening rack 201, drives the fastening gear 403 to rotate counterclockwise, and then meshes with the clamping driven gear 701 through the fastening gear 403 to drive the fastening The worm 7 rotates, the fastening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com