Nucleus pulposus forcep assembling and welding tool and machining process

A technology for assembling welding and assembling tooling is applied in the field of welding and assembling of nucleus pulposus forceps, which can solve the problems of affecting the use effect of nucleus pulposus forceps, reducing the service life of nucleus pulposus forceps, increasing the bite force of forceps heads, etc., so as to improve the use effect and Service life, increase product qualification rate, increase the effect of occlusal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

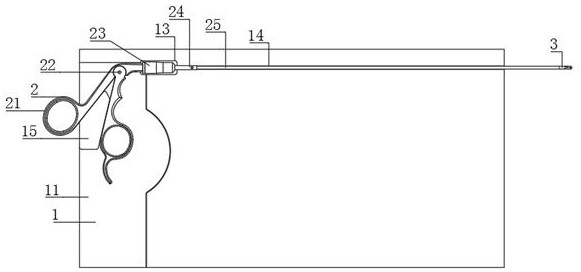

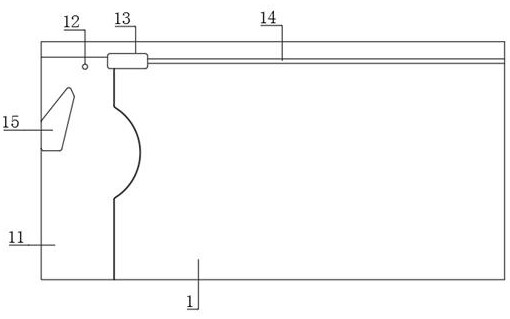

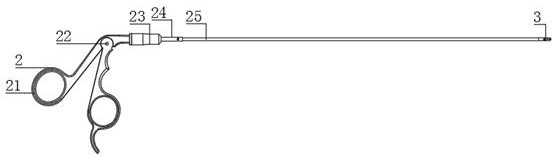

[0034] The present invention provides a nucleus pulposus pliers assembly and welding tool and processing technology, which has an included angle of 25° between the handles 21, and makes the handles have a space of 2° delay, so as to increase the bite force of the pliers head, and further improve the The use effect and service life of the nuclear forceps improve the assembly consistency of the nucleus pulposus forceps and increase the product qualification rate. Please refer to Figure 1-5 , including assembly tooling 1, nucleus pulposus forceps 2 and forceps head 3;

[0035] Further, the inner upper end of the assembly tool 1 is inserted into the nucleus pulposus clamp 2, and the assembly tool 1 includes a nucleus pulposus forceps placem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com