Pump station automatic management system and use method thereof

An automatic management and pumping station technology, applied in pumping stations, waterway systems, pump control and other directions, can solve the problems of manual detection of pumping station safety supervision, inaccurate monitoring, omission of hidden safety hazards, etc., to reduce impact and safety. High, reduce the effect of human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

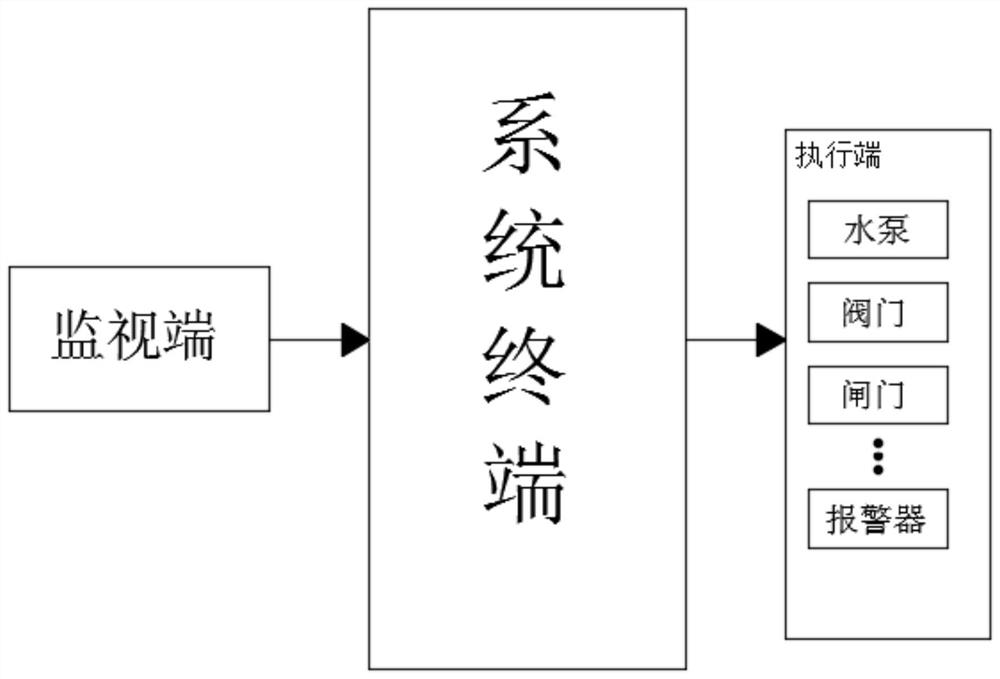

[0042] Embodiment 1. A method of using an automatic pumping station management system, which adopts a pumping station automatic management system, specifically includes the following steps:

[0043] Step 1. Start the equipment at each location of the monitoring terminal, system terminal and execution terminal, and ensure that the equipment can run at any time;

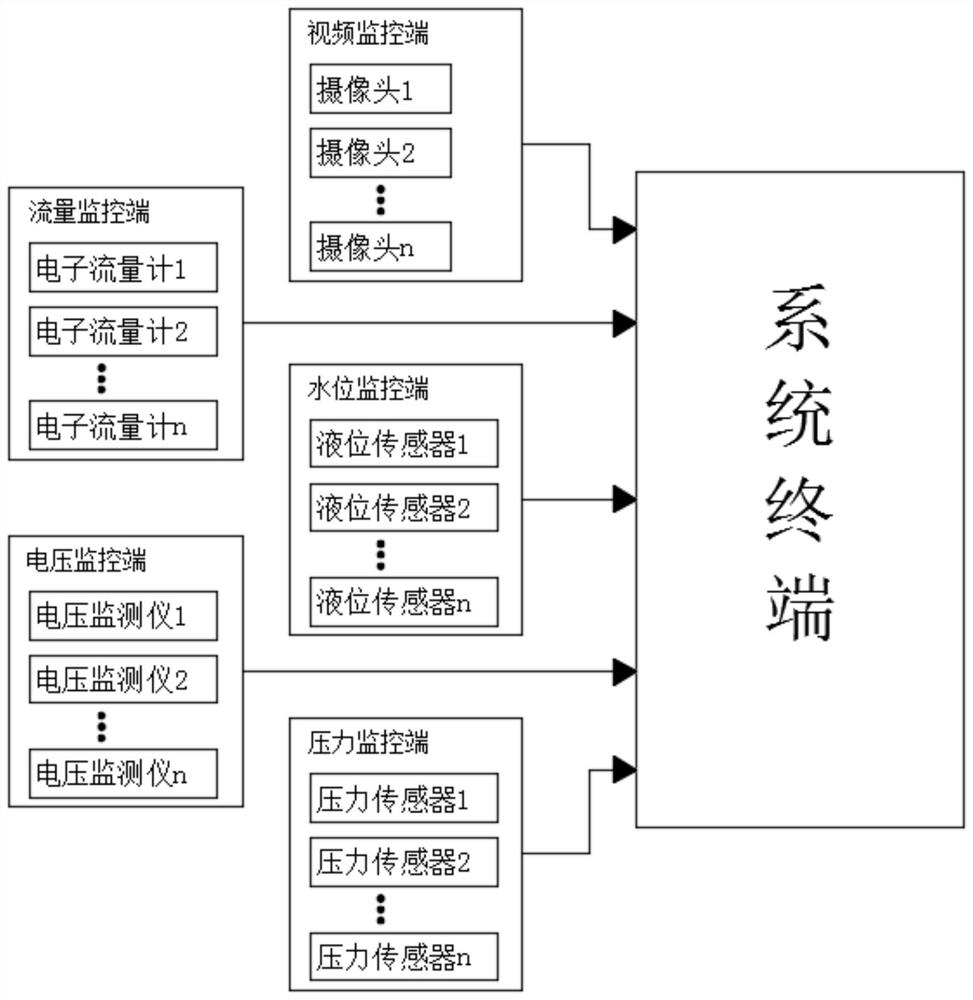

[0044] Step 2. The monitoring terminal obtains various control information, including the real-time water level h 0 , real-time voltage V 0 and the pressure p at each key position 0 At the same time, it is also necessary to monitor whether there is cracking in the dam body or the wall and whether there are large objects floating in the water. The measured pressure includes the pressure at the gate, the dam body and the water pressure at the valve;

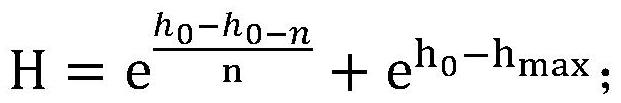

[0045] Step 3: After the monitoring terminal obtains various data and information, the system terminal obtains the information, processes and calculates according to the ...

Embodiment 2

[0062] Embodiment 2, a method for using an automatic pumping station management system, adopting a pumping station automatic management system, specifically includes the following steps:

[0063] Step 1. Start the equipment at each location of the monitoring terminal, system terminal and execution terminal, and ensure that the equipment can run at any time;

[0064] Step 2. The monitoring terminal obtains various control information, including the real-time water level h 0 , real-time voltage V 0 and the pressure p at each key position 0 At the same time, it is also necessary to monitor whether there is cracking in the dam body or the wall and whether there are large objects floating in the water. The measured pressure includes the pressure at the gate, the dam body and the water pressure at the valve;

[0065] Step 3: After the monitoring terminal obtains various data and information, the system terminal obtains the information, processes and calculates according to the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com