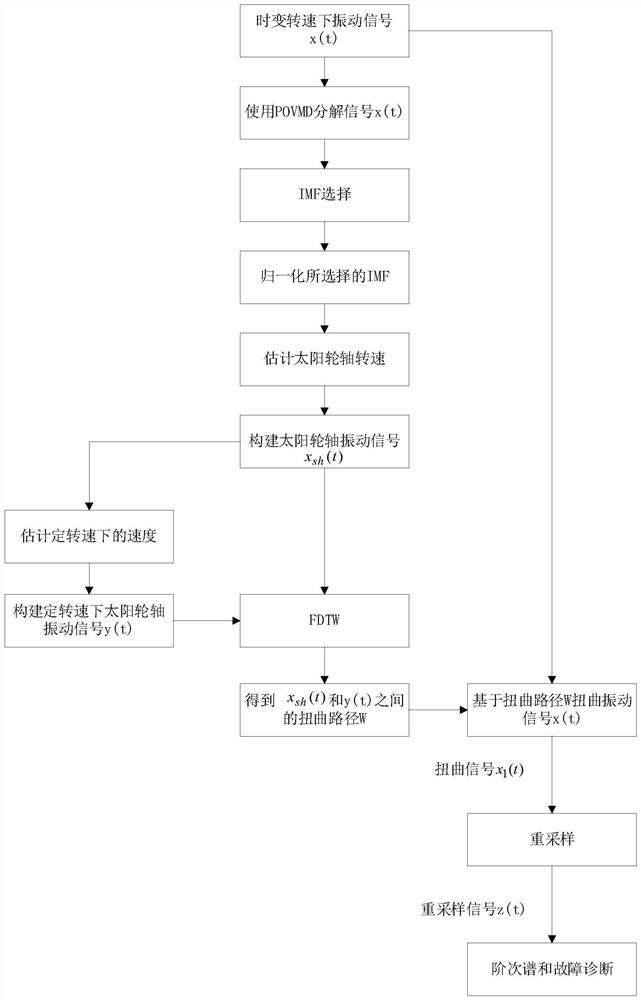

Planetary gearbox fault diagnosis method under time-varying rotating speed based on POVMD and FDTW

A planetary gearbox and fault diagnosis technology, which is applied in the field of fault diagnosis of planetary gearboxes, gears and bearings in planetary gearboxes. Information cannot be obtained accurately, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

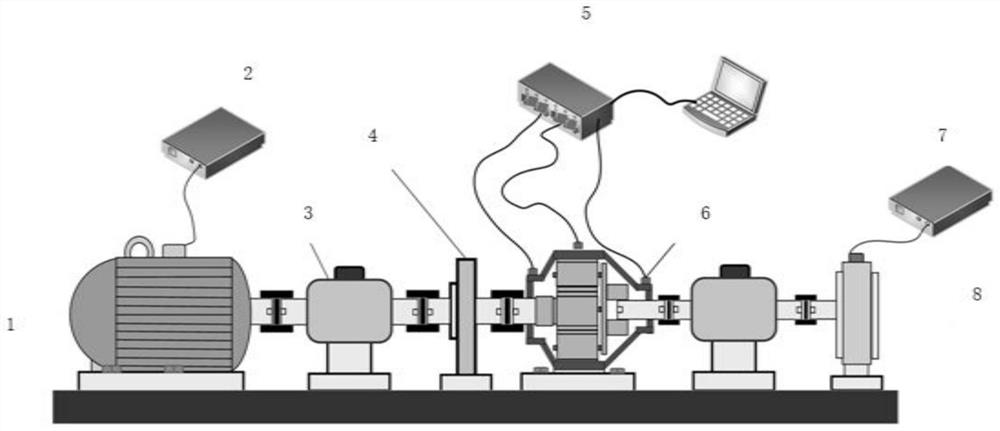

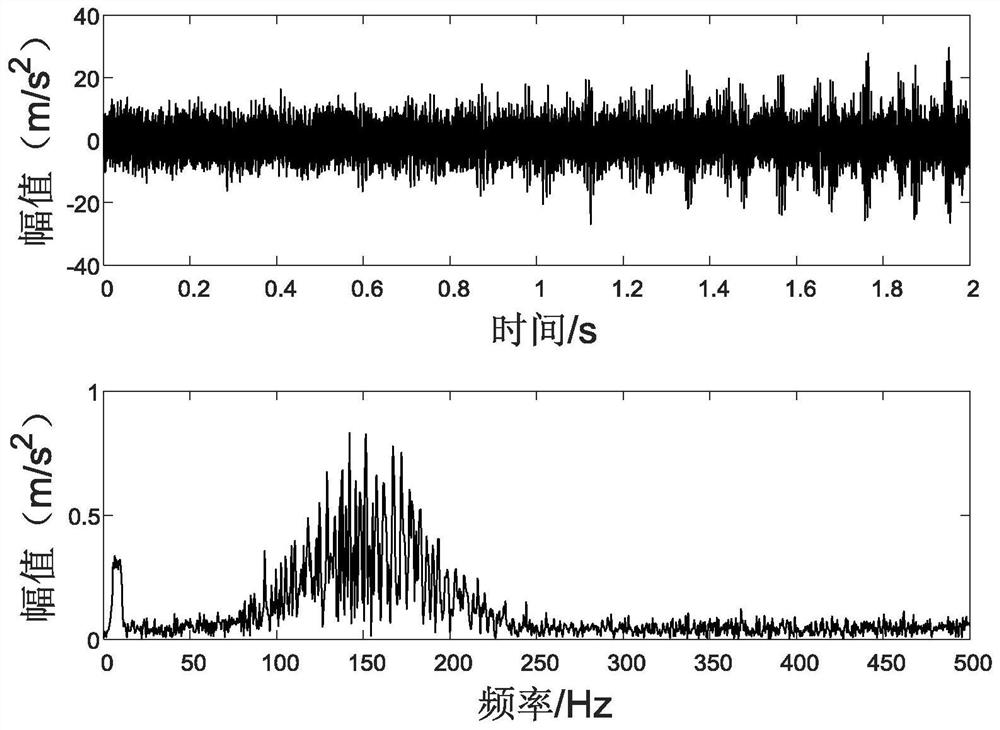

[0094] Build a planetary gearbox fault diagnosis test bench, such as figure 2 shown. The test bench is mainly composed of 1 (drive motor), 6 (planetary gearbox), 8 (magnetic powder loader) and so on. The structural parameters of the planetary gearbox are shown in Table 1. Cut off a part of a tooth of the sun gear by wire cutting technology as a fault. During the experiment, the faulty sun gear was installed in the planetary gearbox to collect experimental data. The acceleration sensor is installed on the vertical, horizontal and axial measuring points of the planetary gearbox casing. The motor input speed increases linearly from 5-8Hz, the data sampling frequency is set to 12800Hz, and the sampling time is 2s. Under the experimental conditions, the order corresponding to the local fault of the sun gear of the planetary gearbox can be calculated as shown in Table 2, where m and k are positive integers.

[0095] Table 1 Gear parameters in planetary gearbox (unit / piece)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com