Carbon-supported platinum nano-catalyst, preparation method thereof, catalyst layer and proton exchange membrane fuel cell

A nano-catalyst and proton exchange membrane technology, applied in solid electrolyte fuel cells, battery electrodes, circuits, etc., can solve the problems of low catalytic efficiency, low production efficiency, and low platinum loading, and achieve high catalytic efficiency and high production efficiency , reduce the effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of described carbon-supported platinum nano-catalyst comprises the following steps:

[0050] Step S1: providing a strong base, a chlorine-containing platinum source, a carbon carrier, and water, wherein the molar ratio of the strong base to the chlorine-containing platinum source is 3-10:1;

[0051] Step S2: mixing the strong base, the chlorine-containing platinum source, the carbon carrier, and water to obtain a dispersion, wherein the pH of the dispersion is 11-14;

[0052] Step S3: drying the dispersion to obtain carbon-supported platinum precursor powder; and

[0053] Step S4: placing the carbon-supported platinum precursor powder in a reducing gas, and performing heat treatment to obtain a carbon-supported platinum nanocatalyst, wherein the carbon-supported platinum nanocatalyst includes a carbon support, and uniformly and dispersedly anchored Platinum nanoparticles on the carbon support.

[0054] In at least one embodiment, the chlorine-co...

Embodiment 1

[0110] Provide 1.5mL sodium hydroxide aqueous solution, 1.0mL chloroplatinic acid aqueous solution, and 160mg carbon black, wherein, the concentration of the sodium hydroxide in the described sodium hydroxide aqueous solution is 0.8mol / L, the chlorine in the described chloroplatinic acid aqueous solution The concentration of platinum acid is 0.2mol / L;

[0111] Mixing the sodium hydroxide aqueous solution and the chloroplatinic acid aqueous solution to obtain a precursor aqueous solution with a pH value of 13;

[0112] Carrying out ultrasonic treatment for the first time to described precursor aqueous solution, wherein, the time of described first ultrasonic treatment is 5min;

[0113] Immersing the carbon black in an aqueous precursor solution to obtain a dispersion;

[0114] Mix the dispersion for 30 minutes at a rotational speed of 200 rpm, and then perform a second ultrasonic treatment on the dispersion, wherein the time of the second ultrasonic treatment is 10 minutes;

...

Embodiment 2

[0121] The difference from Example 1 includes: the concentration of sodium hydroxide in the aqueous solution of sodium hydroxide is 0.6mol / L, the pH value of the aqueous precursor solution is 12, and the carbon-supported platinum nanocatalyst of Example 1 is The platinum content is 30%.

[0122] Other steps are the same as in Embodiment 1 and will not be repeated.

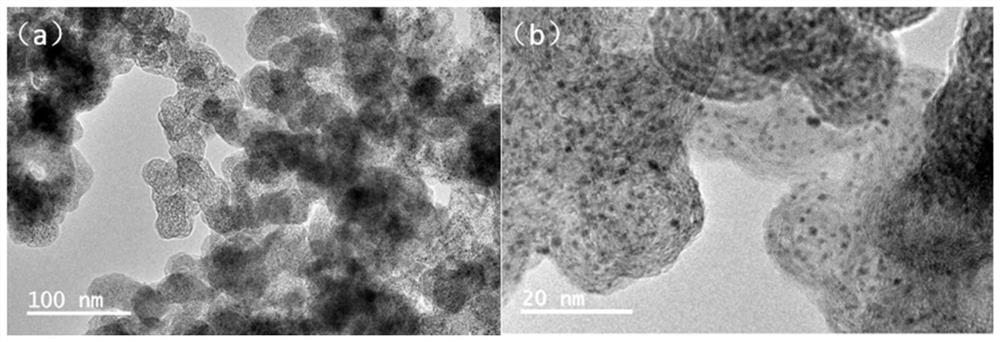

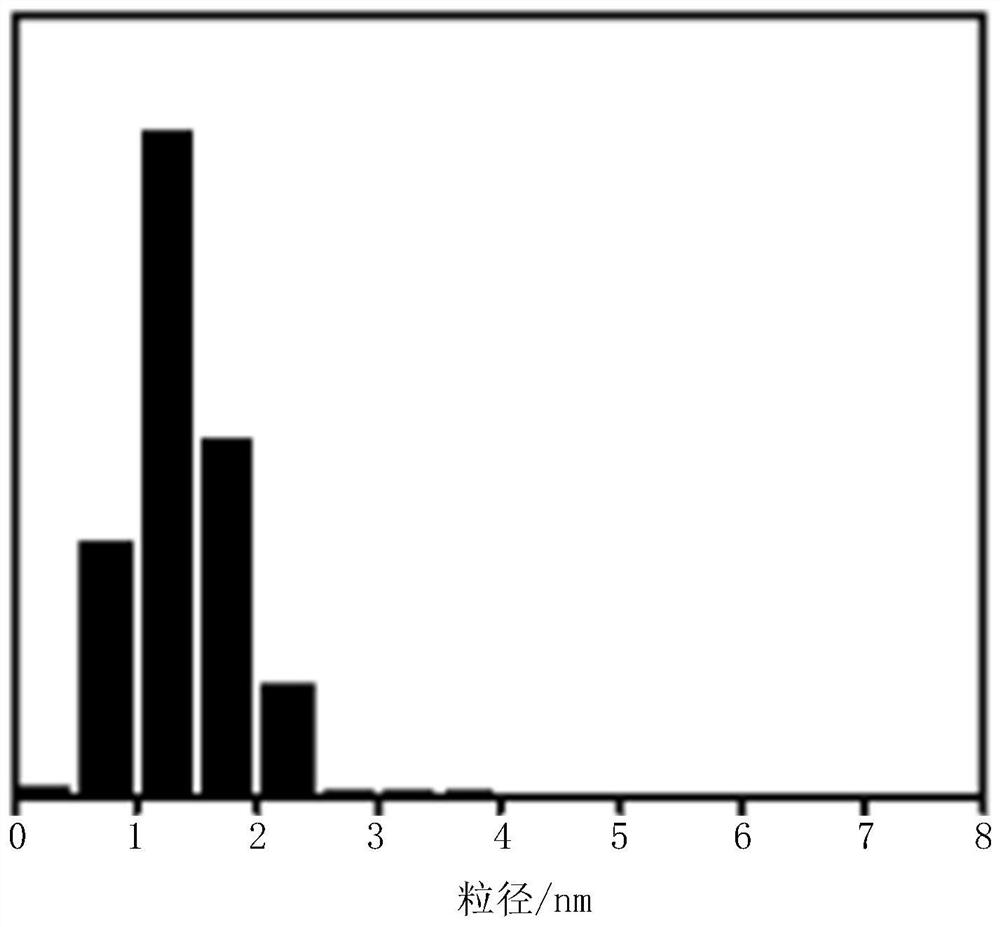

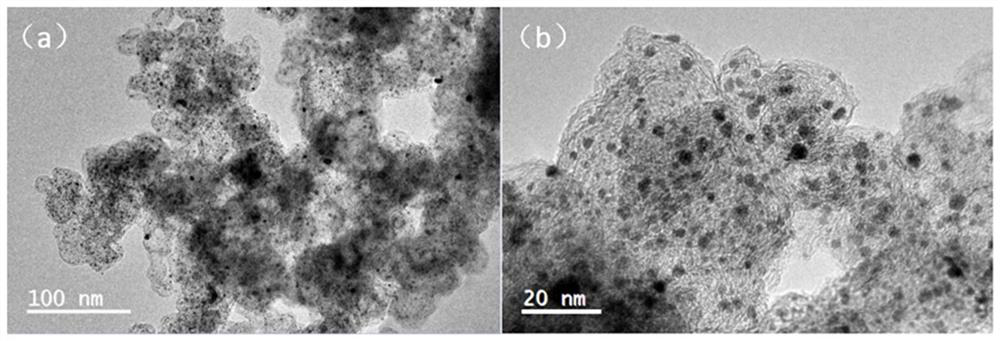

[0123] ginseng image 3 and Figure 4 , in the carbon-supported platinum nanocatalyst of Example 2, the platinum nanoparticles are evenly dispersed on the carbon black, and the particle diameter of the platinum nanoparticles is relatively small, about 2-4 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap