Landscaping engineering tree soil ball excavation and maintenance equipment

A landscaping and equipment maintenance technology, applied in the field of landscaping, can solve the problems of soil secondary drop, trees unable to absorb nutrient solution, soil damage, etc., to avoid secondary damage, shorten the sealing time, and improve the survival rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

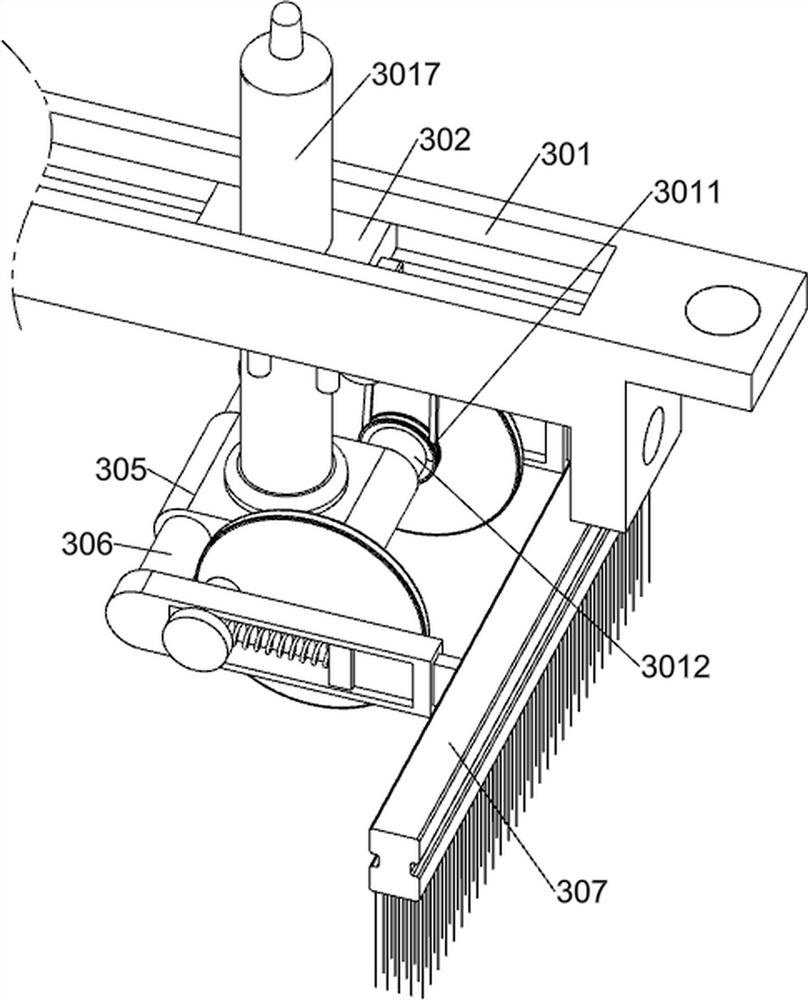

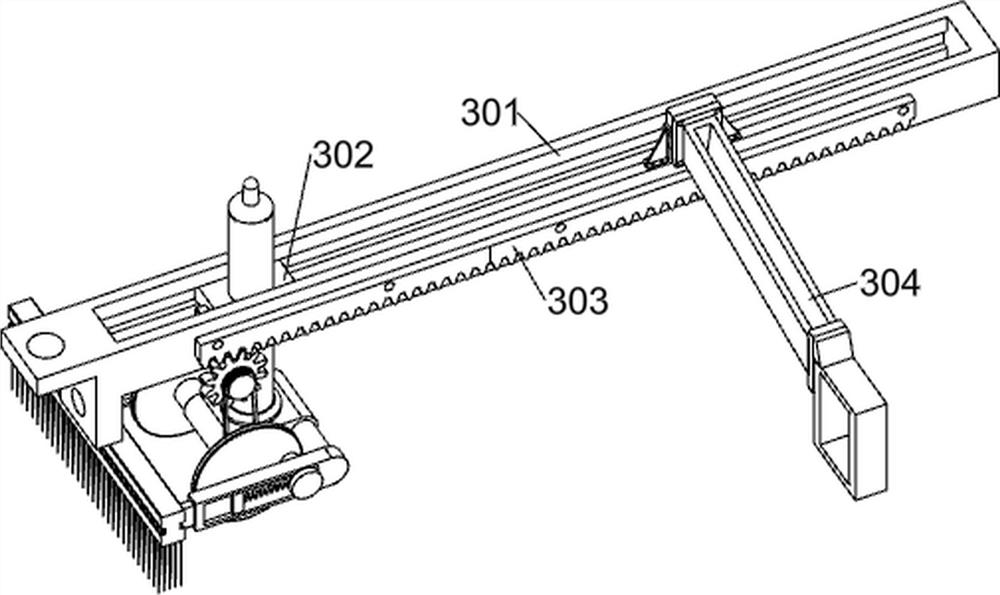

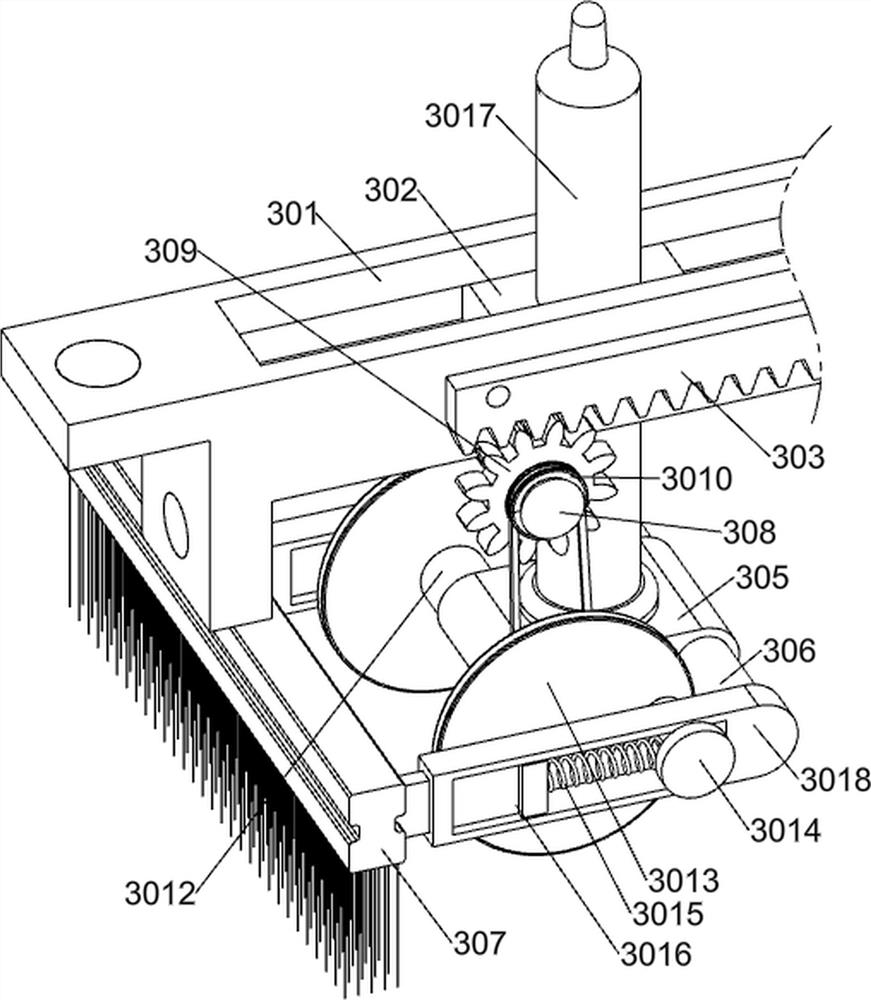

[0031] according to figure 1As shown, a tree soil ball excavation and maintenance equipment for landscaping engineering includes a tree digging head system 1, a tree body fixed maintenance system 2 and a soil ball top maintenance system 3; The fixed maintenance system 2 for the tree body; the left and right parts of the tree excavator head system 1 are each equipped with a soil ball top maintenance system 3 .

[0032] When in use, first fix the digging and maintenance equipment for landscaping engineering tree soil balls to the head of the tree digging machine, then start the tree digging machine to move to the side of the tree to be excavated, and then control the tree digging machine to move the tree digging machine head System 1 circles to the side of the tree, then controls the tree digging machine to start running, controls the tree body fixing maintenance system 2 to fix the tree, fixes the soil ball cloth to the tree digging head system 1, and then controls the tree dig...

Embodiment 2

[0034] On the basis of Example 1, according to Figure 2-4 As shown, the tree-digging machine head system 1 includes an installation base 101, a universal coupling 102, a first installation side frame 103, a connecting seat 104, a fixed L-shaped frame 105, a fixed post 106, a vibration motor 107, and an excavator. Cutter head assembly, blower 1012, liquid spray pipe 1013, installation axle seat 1014 and electric clamp 1015; Installation base 101 left side bolt is connected with first installation side frame 103; First installation side frame 103 is rotatably connected with universal joint Shaft 102; the top front side bolt of the first installation side frame 103 is connected with a connection seat 104; the upper part of the first installation side frame 103 is fixedly inserted with a fixed L-shaped frame 105; the left front side of the connection seat 104 is fixedly inserted with a fixed post 106 The vibration motor 107 is installed on the inside of the fixed post 106; the bo...

Embodiment 3

[0043] On the basis of Example 2, according to figure 1 and Figure 5-6 As shown, the tree body fixed maintenance system 2 includes a mounting frame 201, a middle part cleaning assembly and a clamping assembly; the upper rear middle part of the fixed L-shaped frame 105 is bolt-connected with the mounting frame 201; the middle part of the mounting frame 201 is equipped with a middle part cleaning assembly; The front portion of the frame 201 is equipped with a clamping assembly.

[0044] Before the tree is dug, the clamping assembly can be controlled to fix the tree, and after the tree is dug, the middle cleaning assembly can be controlled to clean and separate the dead leaves on the rear side of the top surface of the soil ball.

[0045] The clamping assembly includes a second electric push rod 207, a third electric push rod 208, a first connecting rod 209, a second connecting rod 2010, a first semicircular splint 2011 and a second semicircular splint 2012; the left front part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com