Novel soft and smooth mold cup and manufacturing process thereof, and bra

A manufacturing process and mold cup technology, which is applied in the field of new silky mold cups, silky mold cup manufacturing technology, and bras with smooth mold cups, can solve the problem of limited comfort improvement of bras, single means of comfort improvement, and mold cups. The cost of the production process is high, so as to achieve the effect of improving air permeability, softness, smoothness and softness, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Based on the user's increasing demand for bra comfort, R&D personnel tend to use improved mold cup materials to improve the softness and air permeability of the mold cup, but this type of comfortable bra often has the following defects:

[0029] 1) The improvement mainly focuses on improving the mold cup structure, lack of innovation in the mold cup structure, and the improvement of bra comfort is limited by the existing mold cup materials;

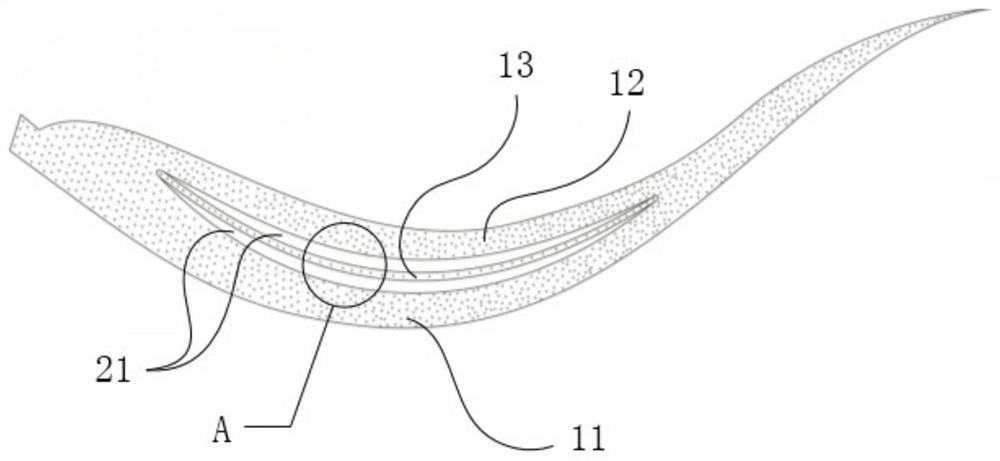

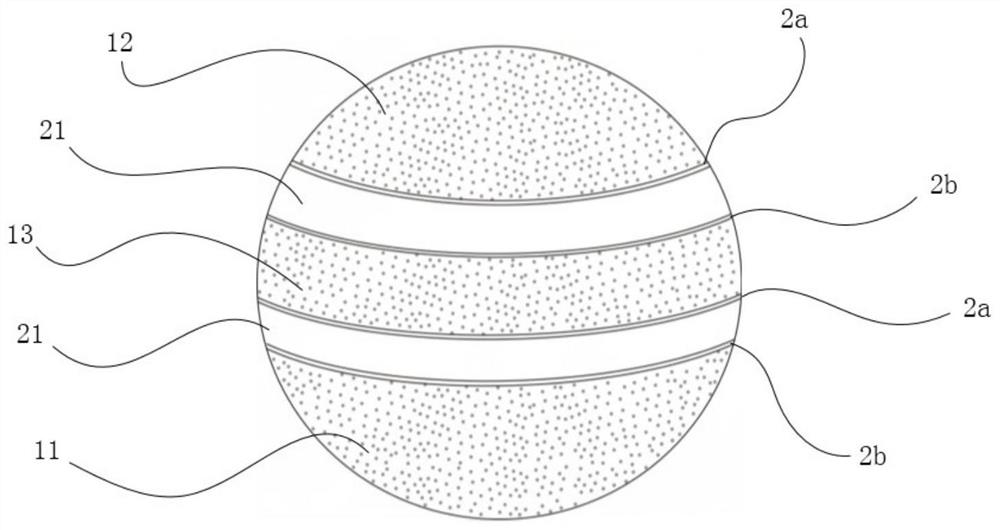

[0030] 2) The mold cup has an integrated structure, and it is difficult to form a slippery feeling between the sponge layers inside the mold cup;

[0031] 3) The cost of the existing mold cup manufacturing process is high and the manufacturing process is complicated.

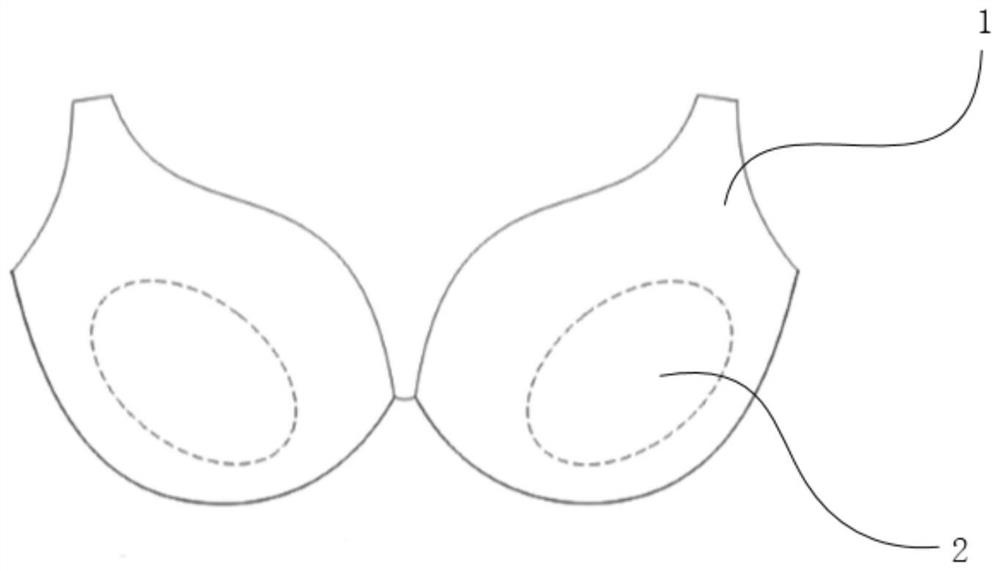

[0032] In order to improve the defects of the existing comfortable bras, the technical solution of the present invention discloses a new type of soft and smooth mold cup, which is different from the situation that the inner layer of the existing mold cup is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com