Multi-group automatic three-strand braid production device

A technology of automatic production and rotating rods, applied in clothing, applications, wigs, etc., can solve problems such as hidden safety hazards, low production efficiency, and existence of equipment during operation, and achieve the effects of saving production costs, improving production efficiency, and avoiding losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

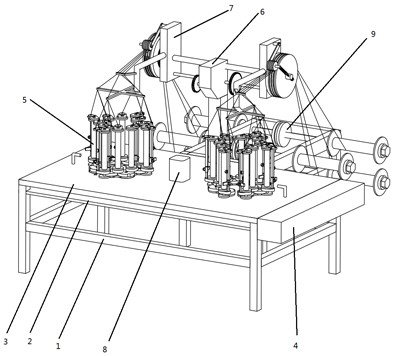

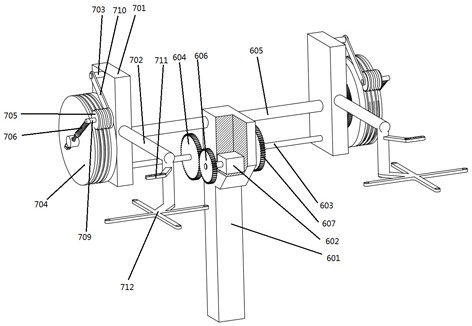

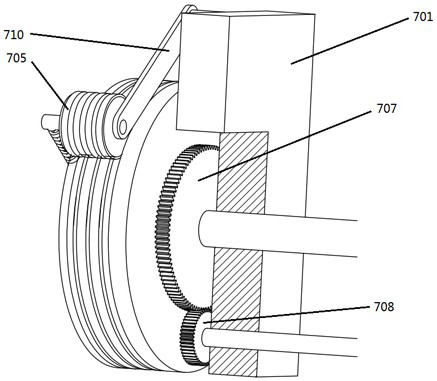

[0035] Example 1, such as figure 1 As shown in —11, the three-strand braid multi-group automatic production device includes a support 1 mechanism, and the support 1 mechanism includes a support 1, an upper plate 3, and a lower plate 2. There are four pairs of circular grooves on each side, the lower plate 2 is located below the upper plate 3; the right side of the bracket 1 is provided with a controller 4, the controller 4 is preferably a Mitsubishi FX2N-64MT-001 controller 4, and the controller 4 is used for Control motor one 8 and motor two 602, the middle part of the upper plate 3 is provided with motor one 8, motor one 8 is preferably a Serre 42HS08 stepping motor, the output end of motor one 8 is provided with a driving gear 10, the left and right sides of motor one 8 Four braiding mechanisms 5 are respectively arranged symmetrically, and a strut mechanism 6 is arranged on the middle rear side of the upper deck 3, and the strut mechanism 6 includes a strut 601, a motor tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com