Automatic positioning device for welding steel wire rods for experiments and using method of automatic positioning device

An automatic positioning and steel wire rod technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems affecting equipment flexibility, inability to position steel wire rods, and inconvenient steel wire rod clamping, etc., to improve the scope of use. and flexibility, convenient testing and testing, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

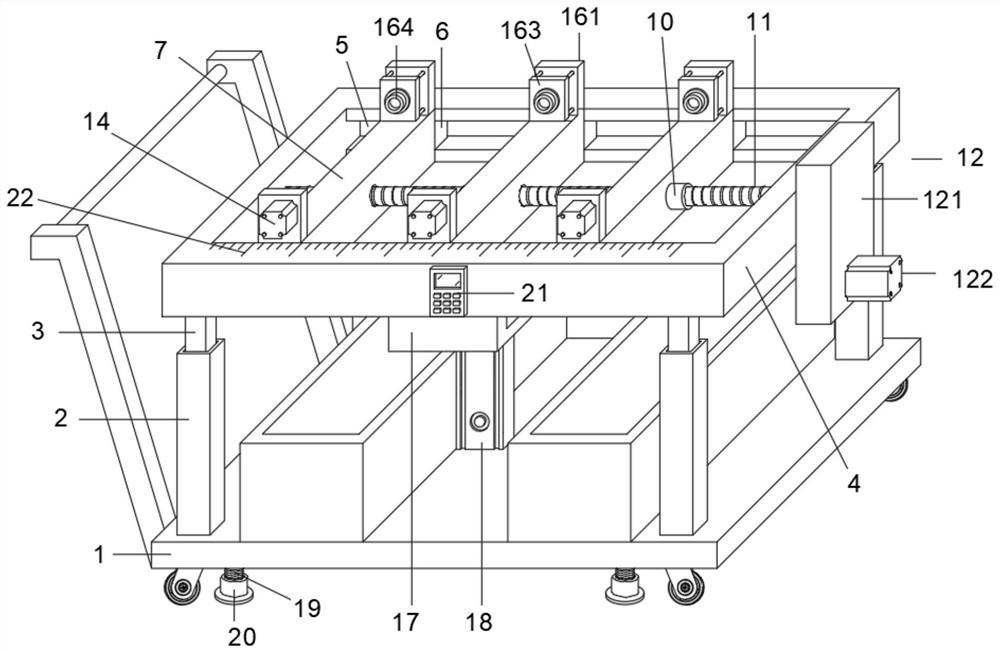

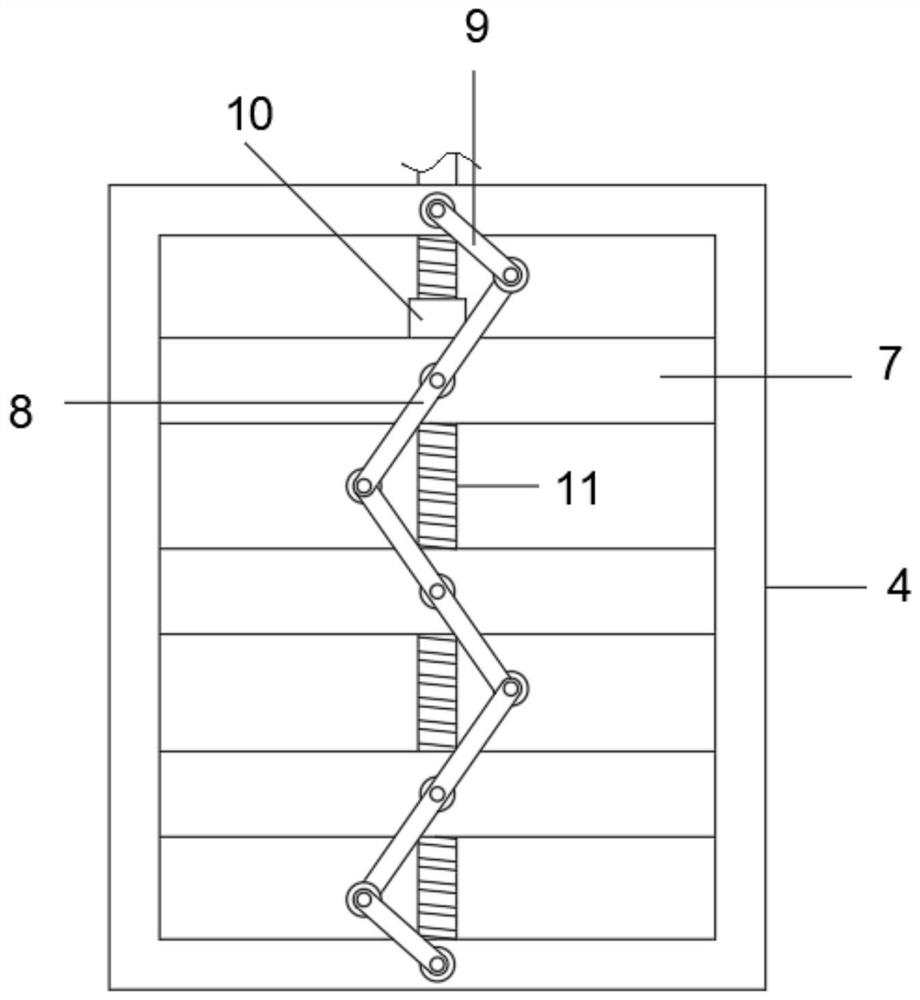

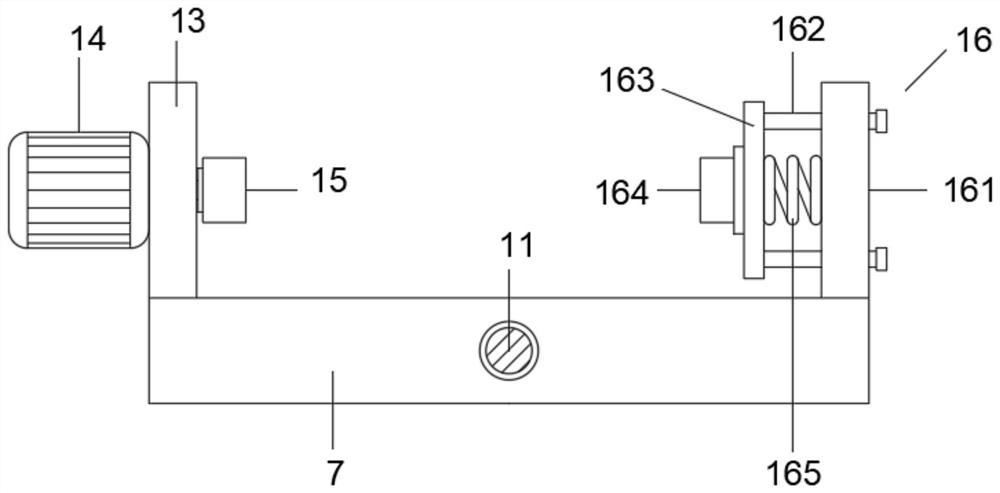

[0027] An automatic positioning device for welded steel wire rods for experiments, comprising a mobile trolley 1, a mounting frame 4, an adjustment plate 7, a drive assembly 12 and a limit assembly 16, the four corners of the top of the mobile trolley 1 are fixedly connected with fixed pipes 2, The inside of the fixed pipe 2 is slidingly connected with a support rod 3, and the top of the support rod 3 extends to the outside of the fixed pipe 2 and is fixedly connected with a mounting frame 4, which is convenient for adjusting the height of the mounting frame 4, thereby driving the steel wire rod to move up and down. The two sides of the inner wall of the mounting frame 4 are symmetrically provided with limiting grooves 5, the inside of the two limiting grooves 5 are slidingly connected with a slider 6, and the two sliders 6 are fixedly connected with an adjusting plate 7, which can prevent the adjusting plate 7 from moving When the offset occurs, it is beneficial to improve the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com