Mortar stirring method

A mixing method and mortar technology, applied in mixing plants, cement mixing devices, chemical instruments and methods, etc., can solve the problems of inaccessibility to buildings or underground construction, paint must be used immediately, manual use is inconvenient, etc., and it can be easily moved Fast, accurate parking and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

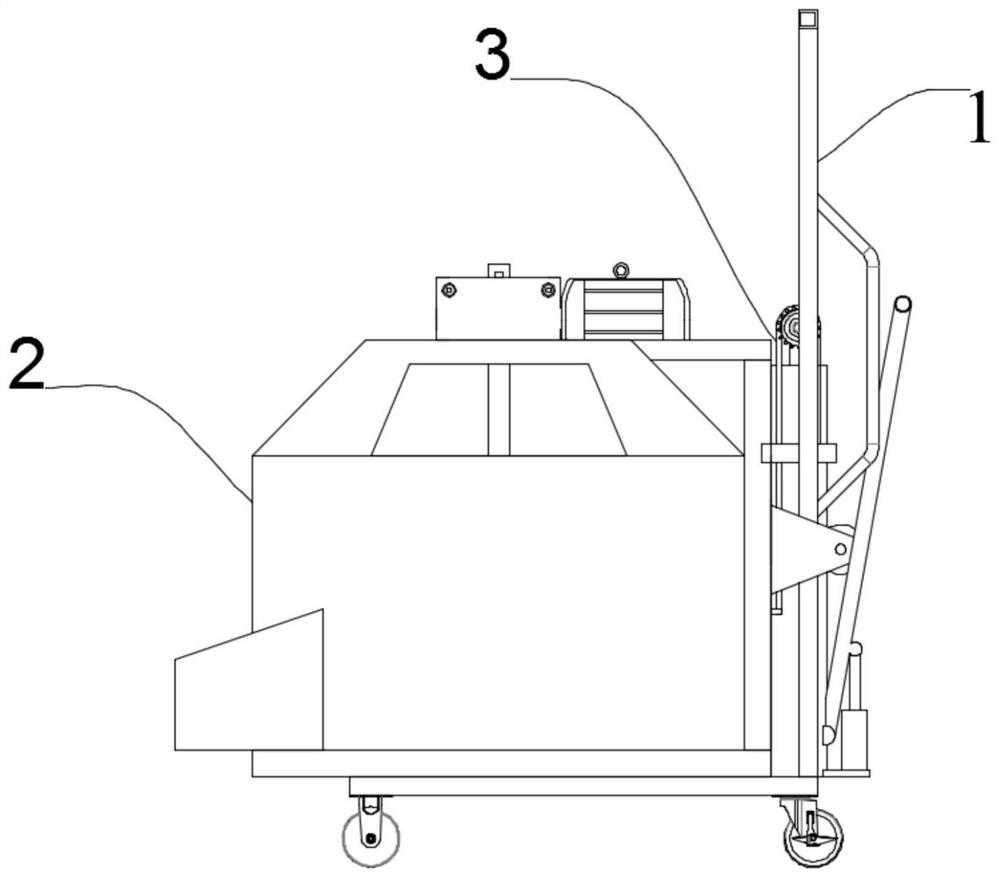

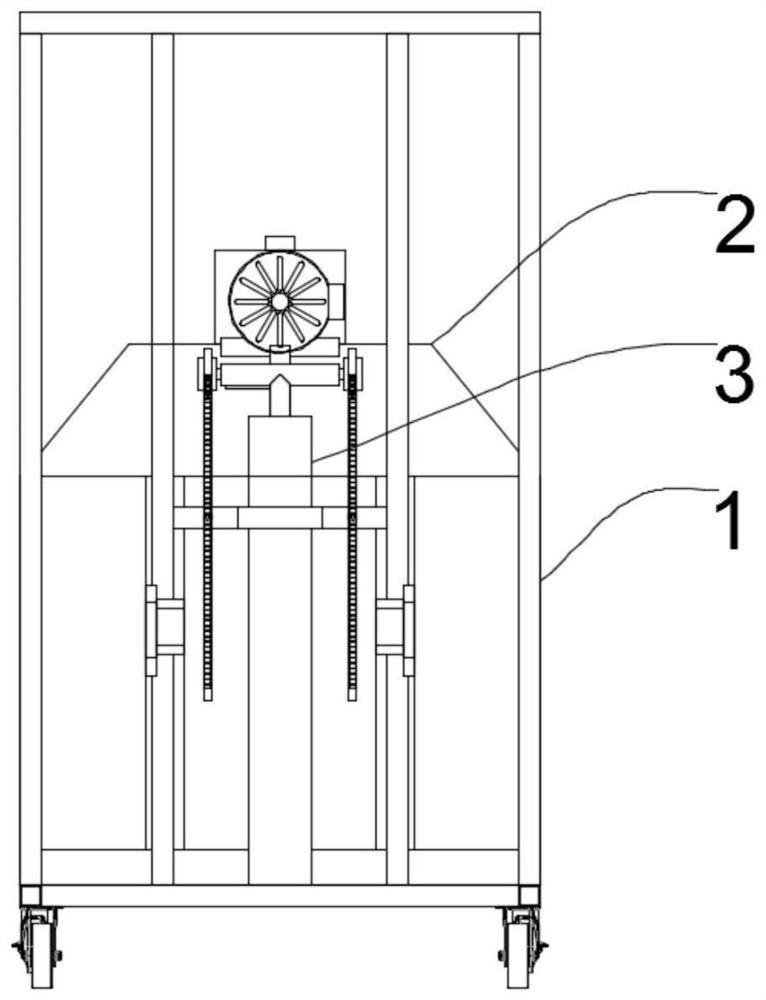

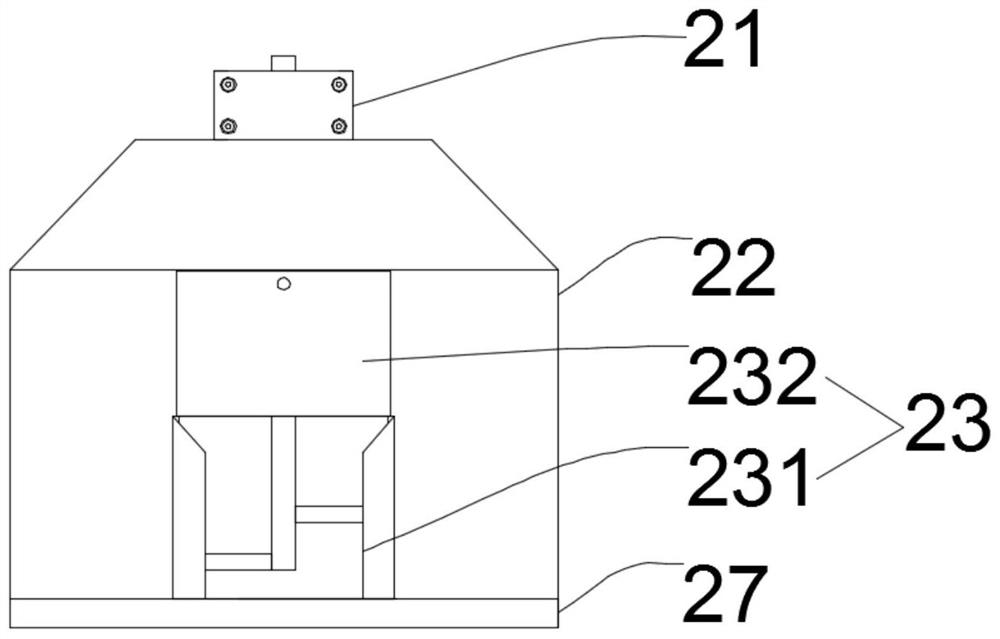

[0055] like Figure 5 As shown, both the bracket 11 and the stand 12 can also be combined into a frame structure with a forward angle of 60°-80°, the stand mixer 2 is arranged in the middle of the stand 12, and Slidingly connected with the stand 12, the lifting device 3 is arranged along the direction of the stand 12, driven by the lifting device 3, the mixed materials in the vertical mixer 2 can be delivered To a certain height of the table, suitable for indoor construction with a mezzanine in the middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com