Cutting apparatus strip for diagnostic kit

A cutting device and test strip technology, applied in the direction of winding strips, transportation and packaging, metal processing, etc., can solve the problems of poor cutting, unusable, defective rate, etc., achieve precise concentric adjustment, prevent bending, and eliminate defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

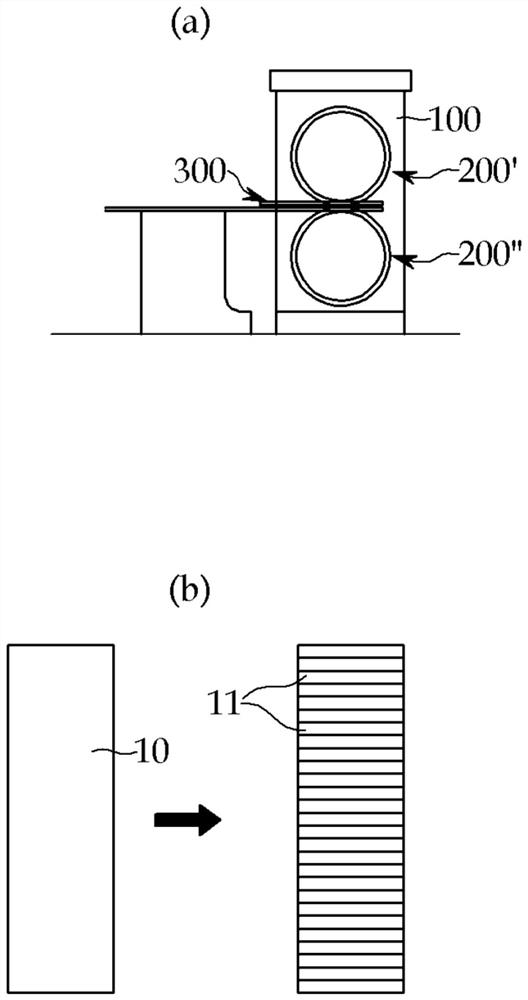

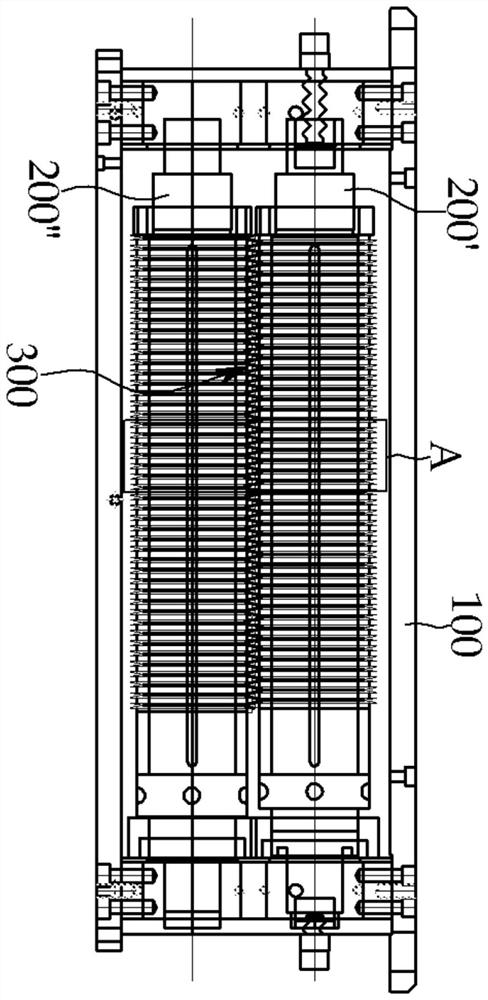

[0063] The test strip cutting device for diagnostic test paper of the present invention [embodiment 1] is, as Figure 1 to Figure 7 As shown, in terms of its structure, the diagnostic test paper 10 provided in a long plate shape can be cut into a plurality of test paper strips 11 formed in a strip along the width direction, and its structure includes a frame 100, a first shaft 200 ', the second shaft 200" and the guide member 300.

[0064] In particular, the guide member 300 is set through the first shaft 200' and the second shaft 200", and then supports the two sides of the diagnostic test paper 10, and the blade 211 is facing the first shaft 200' and the second shaft 200". The second shaft 200" can be cut into test strips 11 at the same time as it rotates, so that the diagnostic test strip 10 can be cut into test strips 11 under the condition that both sides are supported. Not only can the test strips 11 be cut according to the predetermined shape, but also can be prevented ...

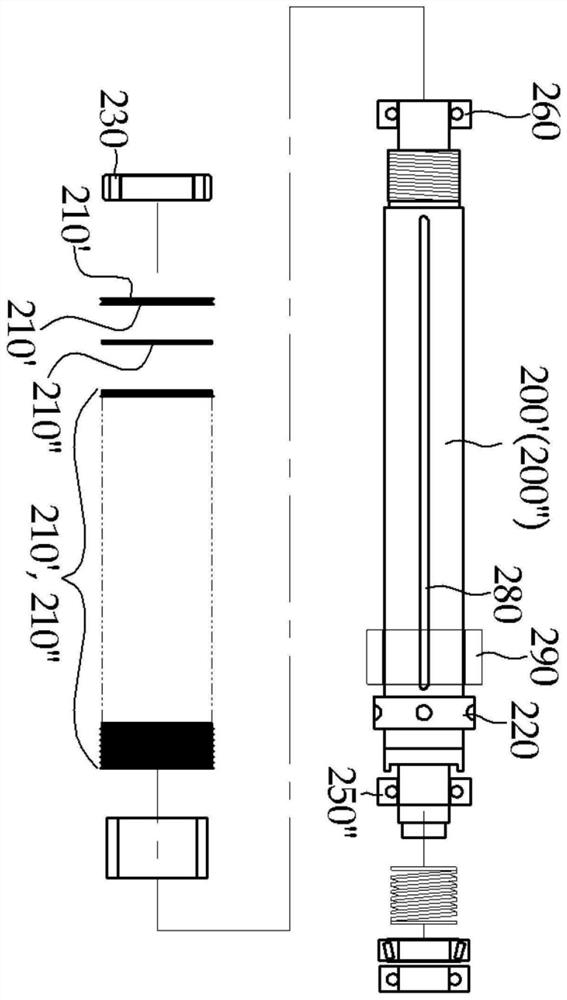

Embodiment 2

[0095] The test strip cutting device for diagnostic test paper of the present invention [embodiment 2] is, as Figure 8 As shown, the structure is the same as the above-mentioned [embodiment 1], but the difference is that a structure that can make it flow in the longitudinal direction is added on the first shaft 200'. Therefore, the supplementary structure will be mainly described here, and the rest of the structures that are the same as the above-mentioned [Embodiment 1] will not be described in detail.

[0096] [Example 2] Yes, such as Figure 8 As shown, the first shaft 200' can be adjusted to move along its length direction, and then the distance between the blades 210' assembled on the first shaft 200' and the second shaft 200" can be adjusted, so that the diagnostic test strip 10 can be better to cut.

[0097] To this end, on the first axis 200', as Figure 8 As shown, at least one tapered bearing 250' is additionally provided on one side, so that the first shaft 200'...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com