Novel loading method for segment assembly bridge girder erection machine load test

A technology of load test and bridge erection machine, which is applied in the direction of spring mechanism, mechanical component testing, machine/structural component testing, etc., to save manpower and material resources, prevent slippage, and prevent beam damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be described below in conjunction with the embodiments of the present invention, as described herein is merely, not all of the embodiments of the invention, not all of the embodiments of the invention. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

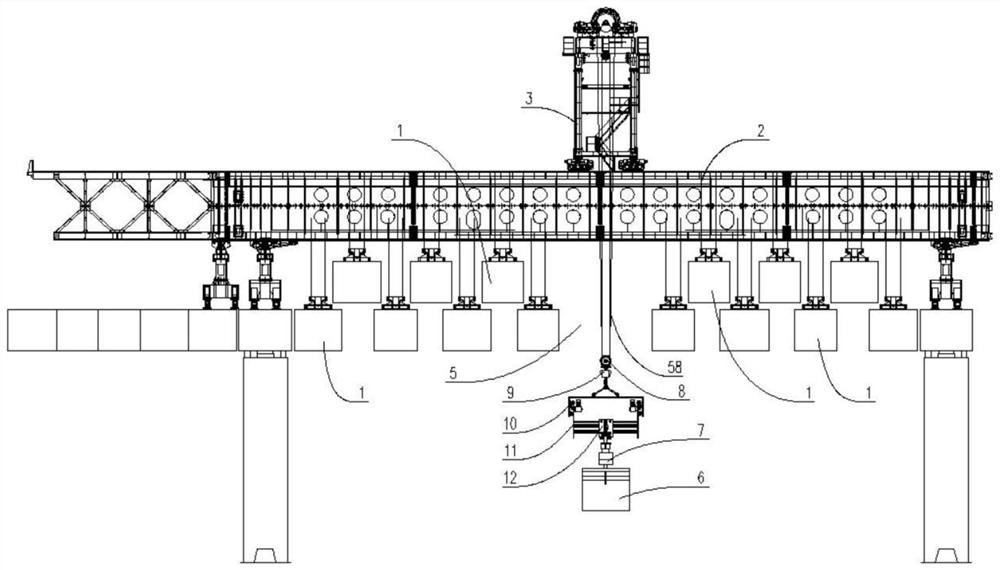

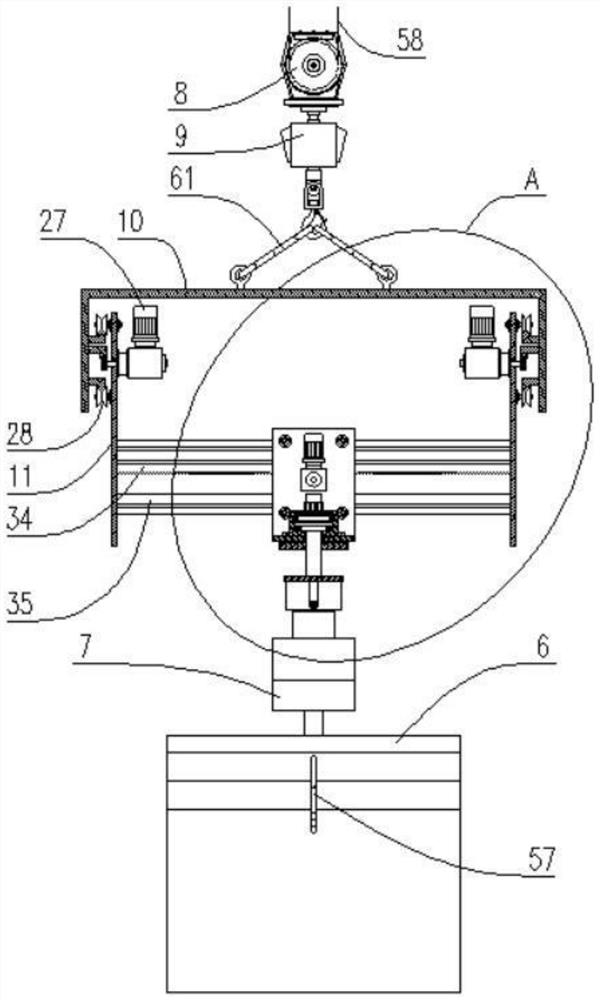

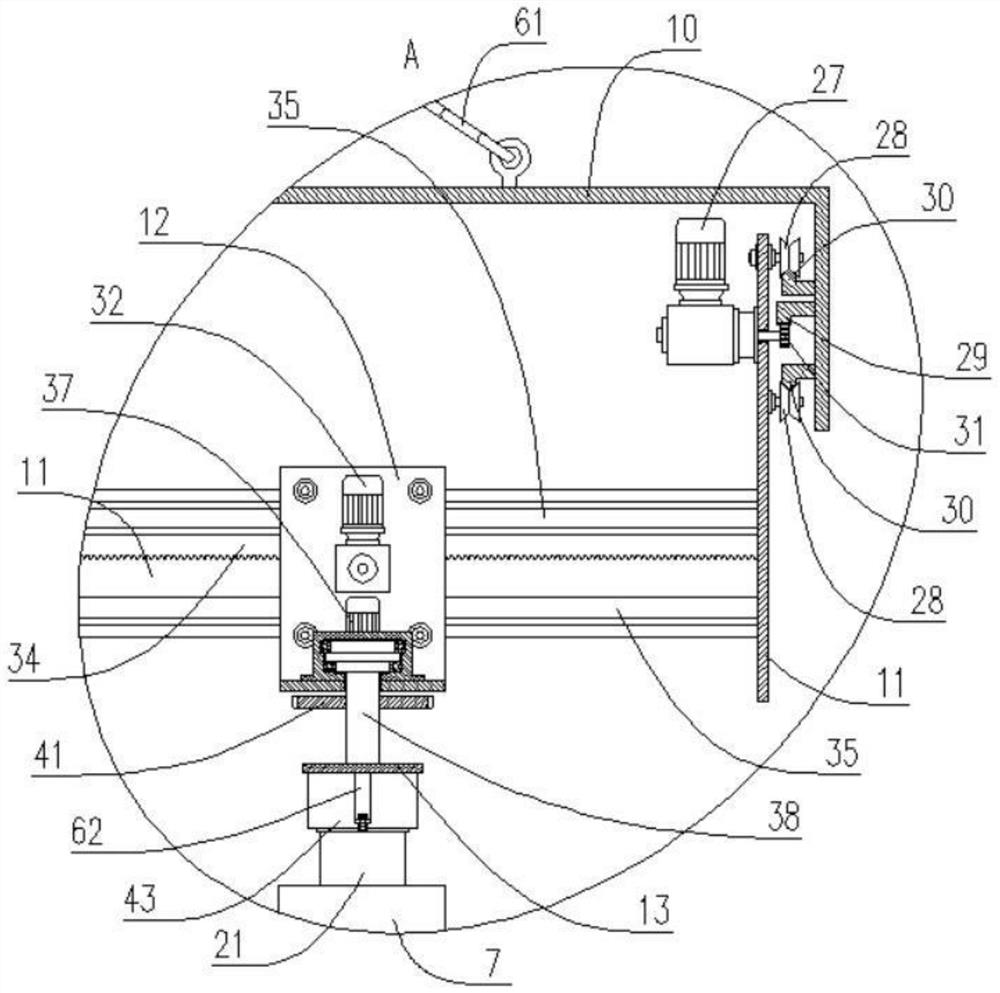

[0040] Refer figure 1 , A new segment assembled bridge load test method, including the following steps:

[0041] Step 1: After the segment assembly bridge is evenly hanging, all segment block 1 is hung, and the offset space 5 of the heavy-day 3 spreader is reserved in the cross-section of the segment assembly bridge main frame 2. Place a weighting segment block 6 below the ground below 5;

[0042] Step 2: Move the spreader to the lower space 5 by the lifting temperature 3, decease the spreader, so that it passes from the of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com