Underwater buoyancy tank separation structure and separation method suitable for hexagonal barrel type foundation overwater prefabricated platform

A technology of cylindrical foundation and separation structure, which is applied to underwater structures, foundation structure engineering, water conservancy projects, etc., can solve the problems of restricting the direction of transfer and removal of cylindrical foundations, and the inability of floating ships to enter, etc. The effect of reusable, safe and efficient transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

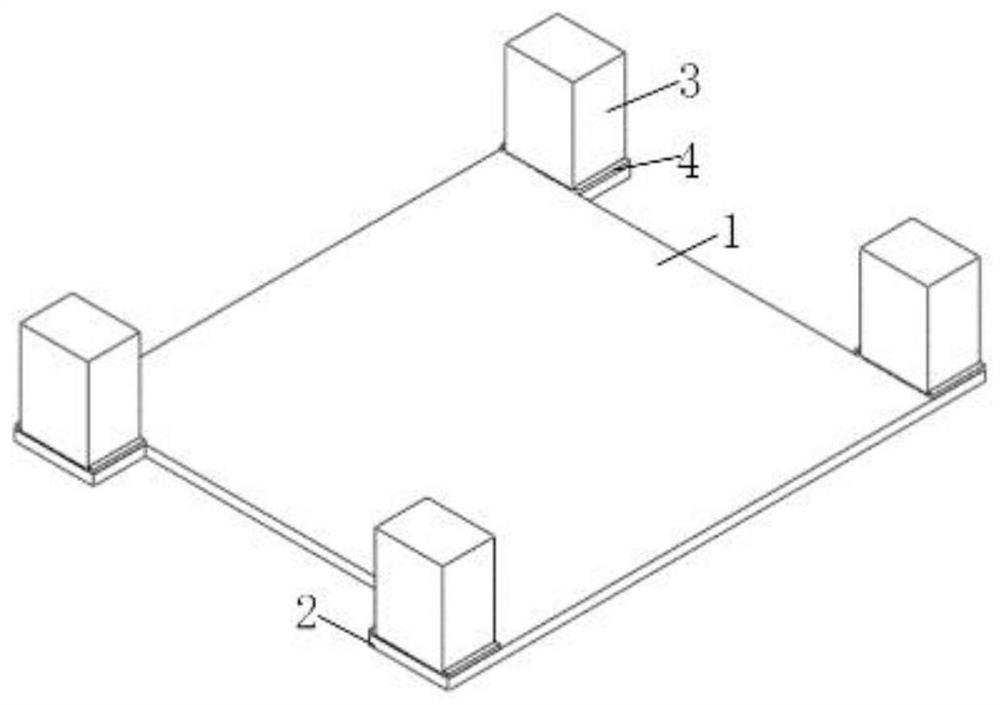

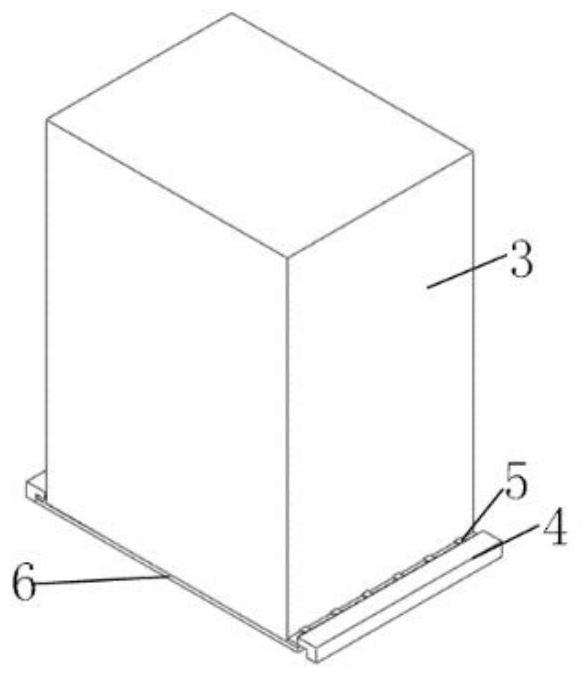

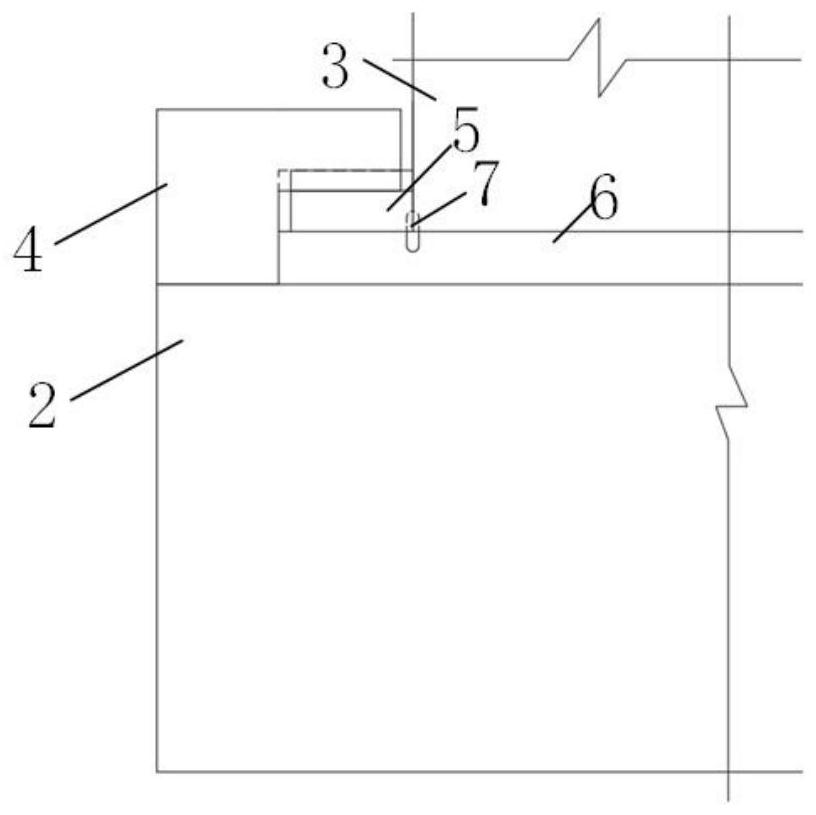

[0032] Such as Figures 1 to 10 As shown, an underwater floating tank separation structure suitable for a prefabricated platform on a hexagonal cylindrical foundation, the structure includes a main platform 1, a permanent dry cabin 2, a separate floating tank 3, buckles 4, and racks 5 , air cushion 6 and roller 7.

[0033] Such as Figure 1 to Figure 3 As shown, the four corners of the main body platform are each provided with a permanent dry compartment 2 for placing a detached pontoon, and the bottom of the opposite side of the detached pontoon 3 is respectively provided with a bayonet rack 5 (such as figure 2 with 3 As shown), a group of rollers 7 are respectively installed on the lower part of the card racks, and a brake device (omitted in the figure) is also arranged on the rollers, and a position corresponding to each card rack on the permanent dry cabin is respectively provided with a card rack The matching buckle 4 has a buckle slot corresponding to each tooth at t...

Embodiment 2

[0037] A method for separating underwater floating tanks suitable for prefabricated platforms above water with hexagonal cylindrical foundations, comprising:

[0038] 1. When the prefabricated platform on the water is floated as a whole, the separate buoyancy box moves to the buckle position on the permanent dry cabin under the action of the rollers, and the position is adjusted to reach all the teeth on the rack and the buckle. The buckle slots can be meshed with each other. At this time, the interior of the air cushion is inflated, and the jacking separation buoy box moves upward to make the rack and buckle mesh with each other, the roller brakes, and the air valve of the air cushion closes;

[0039] 2. When the platform arrives at the prefabricated site, the platform is in a floating state, and the tubular foundation tube skirt part is constructed (see Figure 5 ), as the weight of the upper structure of the platform increases, the draft of the platform increases gradually;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com