Continuous deslagging device and method for vertical shaft

A shaft and locking device technology, which is applied to shaft equipment, earth-moving drilling, mining equipment, etc., can solve the problems of discontinuous slag discharge, slag particle blockage, and low efficiency, so as to reduce the downhole failure rate, suppress dust, The effect of simple underground structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

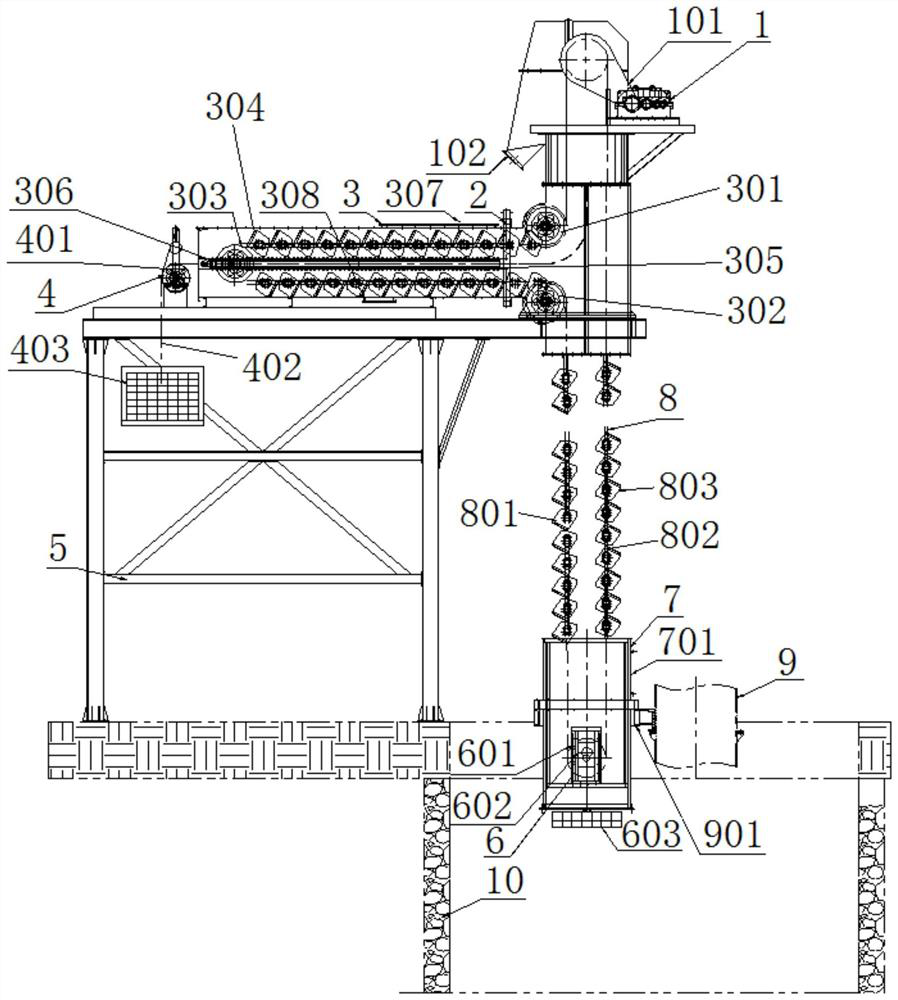

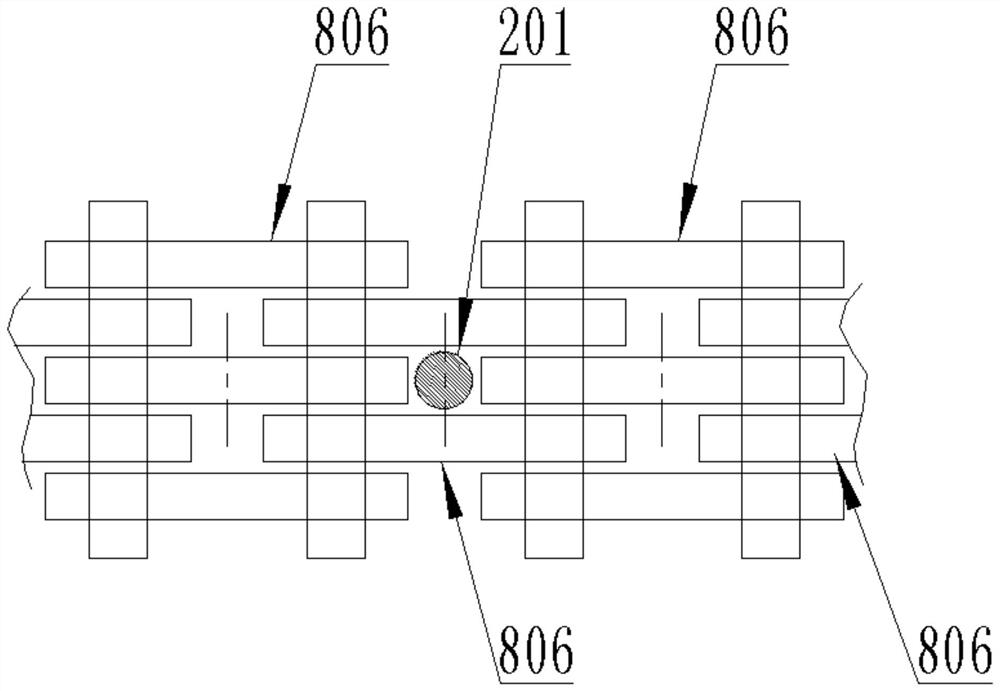

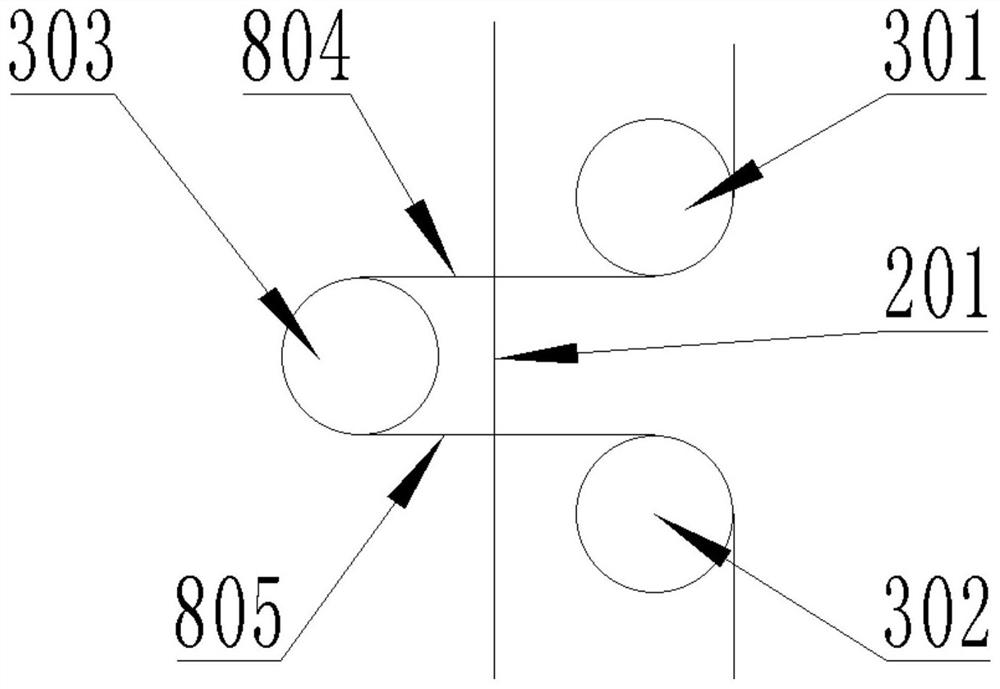

[0034] A continuous slagging device for a vertical shaft, the continuous slagging device for a vertical shaft includes a conveying system 8, a chain storage device 3 and a locking device 2, the chain storage device 3 includes a first redirection and fixed shaft group 301, The second reversing fixed shaft group 302 and reversing moving shaft group 303, conveying system 8 contains conveying chain 801, and conveying chain 801 contains chain 802 and chain bucket 803, and chain 802 bypasses first reversing fixed shaft group 301, revamping To the moving shaft group 303 and the second redirecting fixed shaft group 302, two adjacent chain links 806 in the chain 802 are detachably connected, located between the redirecting moving shaft group 303 and the first redirecting fixed shaft group 301 A section of conveyor chain 801 is the first conveyor chain section 804, and a section of conveyor chain 801 between the reversing moving shaft group 303 and the second reversing fixed shaft group ...

Embodiment 2

[0060] This embodiment is a change to Embodiment 1. The main difference between this embodiment and Embodiment 1 is that the first reversing fixed shaft group 301 and the second reversing fixed shaft group 302 are arranged on the left and right, and the reversing moving shaft group 303 is located on the front side, rear side, upper side or lower side of the first redirecting fixed shaft group 301, such as Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com