Fan blade fault prediction method and system and storage medium

A technology for wind turbine blades and fault prediction, applied to wind turbines in the same direction as the wind, wind turbines, neural learning methods, etc., can solve problems such as large manpower input, complex working environment, and failure to reflect blade damage, and achieve enhanced operation The effect of maintenance and avoiding breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

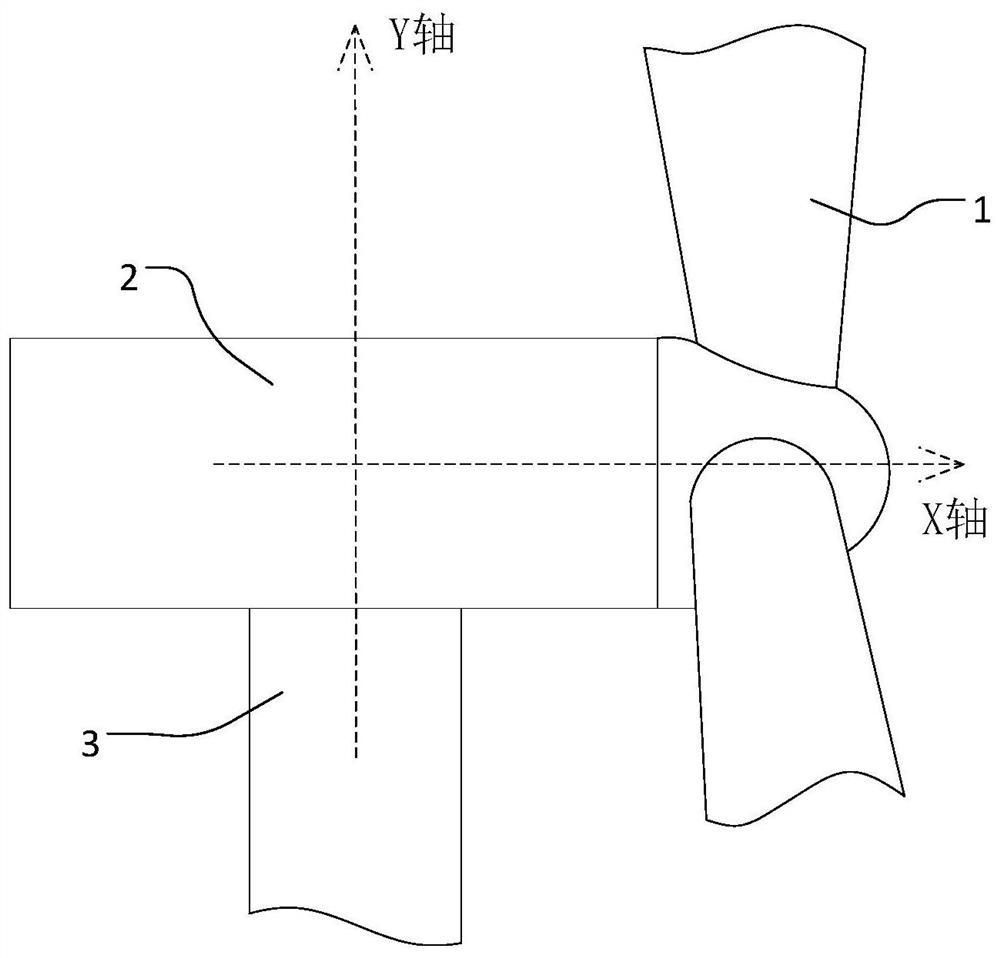

[0032] This application provides a deep learning-based fault prediction method for wind turbine blades on the basis of existing wind farms without adding new structural elements. The general structure of wind power generator (referred to as fan in this application) is as attached figure 2 As shown, including blade 1, nacelle 2 and tower 3, in nacelle 2, a data collection element (not shown) for collecting various data in the wind turbine operation process is provided, the blade failure prediction method in the present application The probability of wind turbine blade failure is predicted from existing operational data collected by these data collection elements.

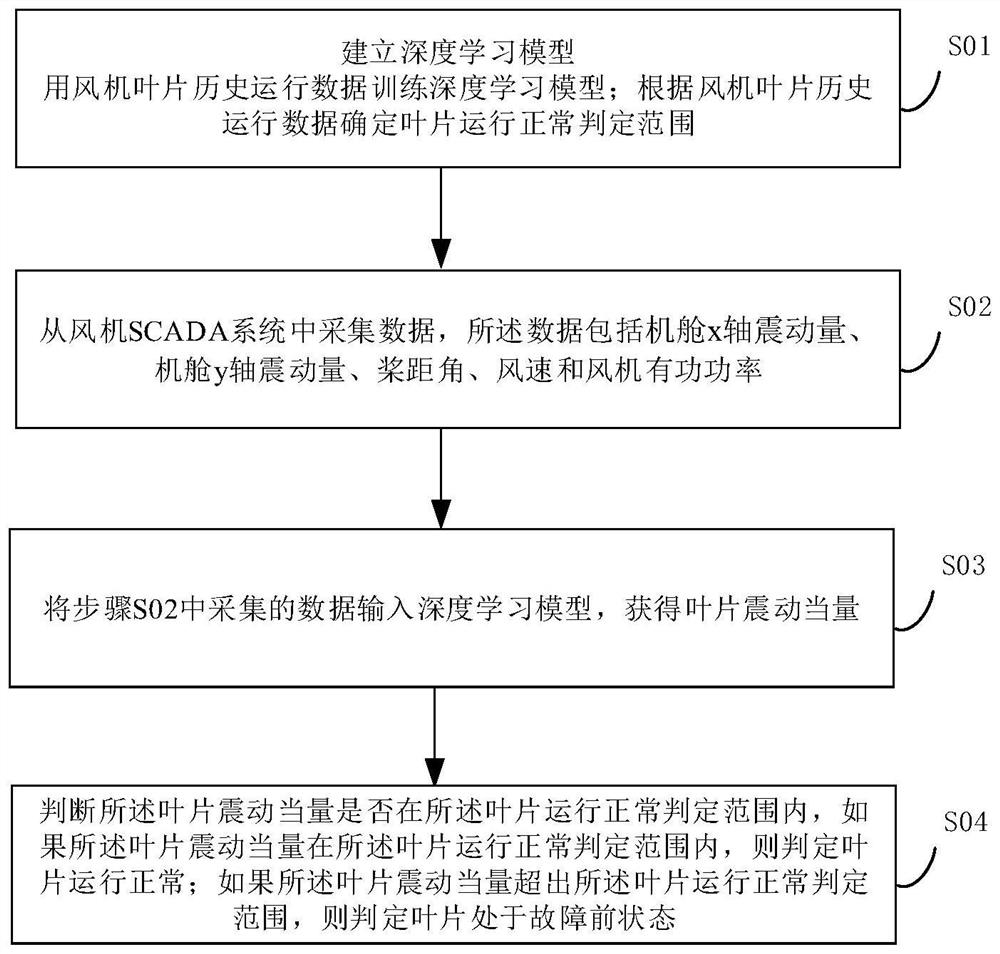

[0033] See attached figure 1 , the prediction method in this application includes the following steps:

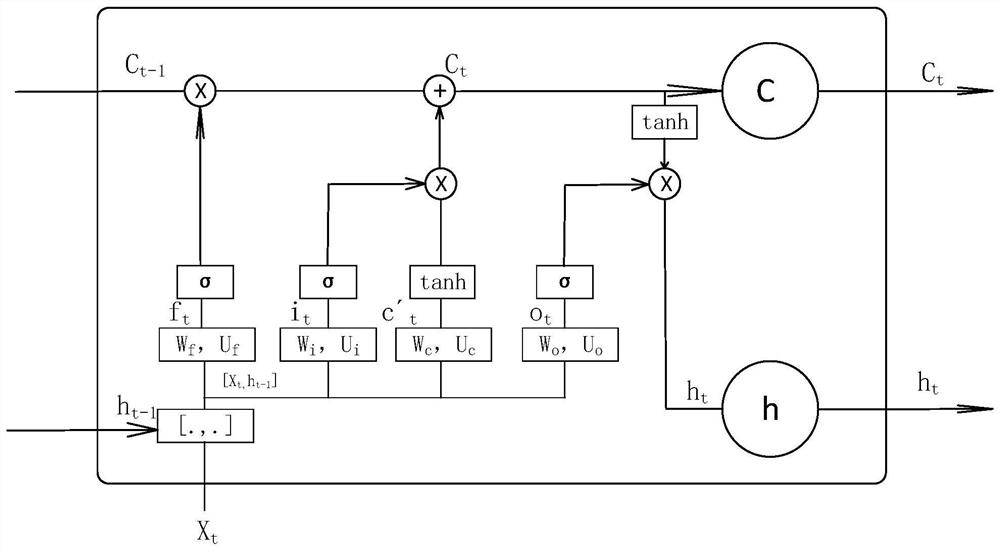

[0034] Step S01: establish a deep learning model, the input of the deep learning model includes the vibration of the x-axis of the cabin, the vibration of the y-axis of the cabin (such as figure 2 As shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com