A micro-control air supply adjustment valve test bench

A technology of regulating valve and test bench, applied in mechanical valve testing, manufacturing tools, workpiece clamping devices, etc., can solve the problem of affecting the repair progress and quality, unable to guarantee the performance of the air supply adjustment valve, and difficult to replace the air adjustment valve. and other problems, to achieve the effect of eliminating the need for personnel intervention, saving human resource waste, and improving the efficiency of vehicle repairing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

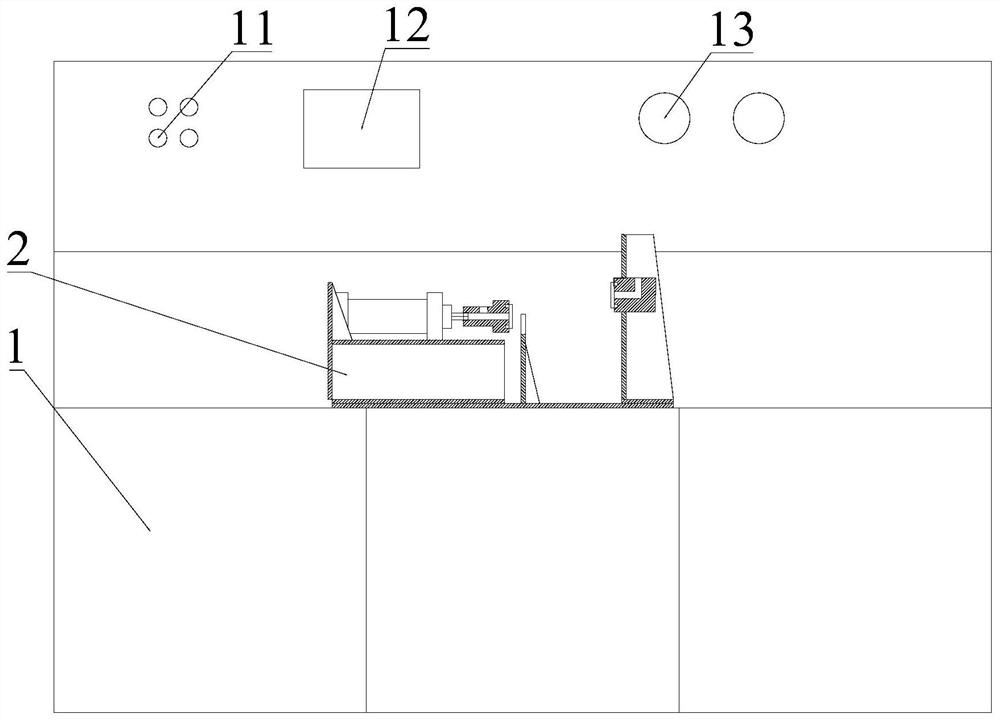

[0037] refer to figure 1 , this embodiment discloses a micro-control air supply adjustment valve test bench, including a host system and a control system, the host system includes a cabinet 1, a test clamping device 2, and an air circuit system;

[0038] Cabinet 1 is a square integral structure, and its frame is welded by square tubes, which can ensure the quality well and is not easy to deform;

[0039] At the same time, the surface of the cabinet 1 is treated with plastic spraying, which is not only anti-corrosion, but also beautiful;

[0040] The inside of the cabinet 1 is equipped with a starting disk, a filter pressure reducing valve, an electromagnetic on-off valve, an electromagnetic reversing valve, a pressure sensor and other electrical components.

[0041] The cabinet 1 is also provided with operation buttons 11 , a touch screen 12 and a pressure gauge 13 .

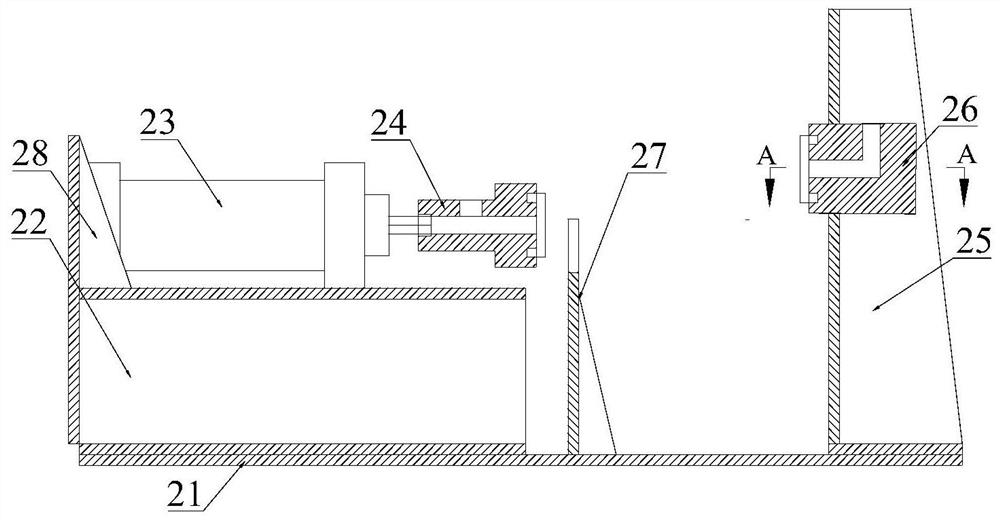

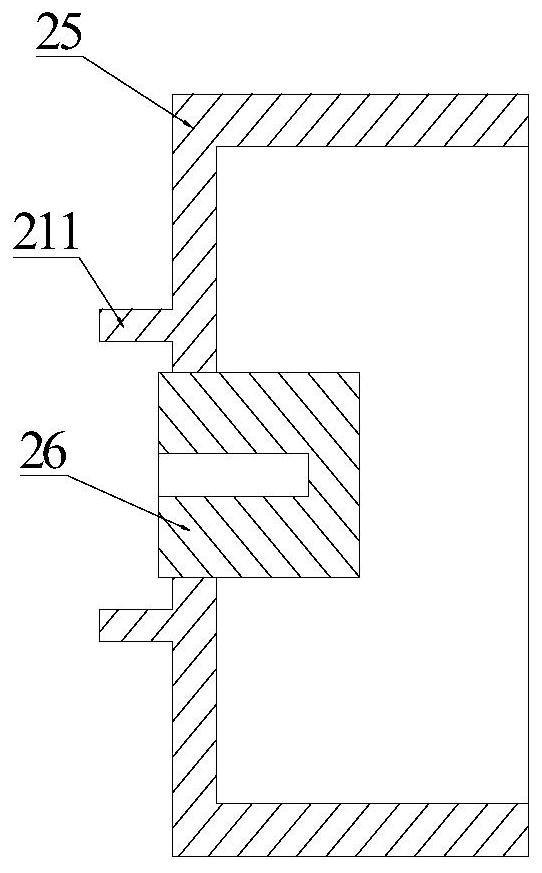

[0042] refer to figure 2 and image 3 , the test clamping device 2 includes a base plate 21, a support 2...

Embodiment 2

[0089] refer to Figure 5 The difference between this embodiment and the first embodiment is that the test clamping device 2 is also provided with a positioning sleeve shaft 29 and a positioning sleeve 210; the positioning sleeve shaft 29 is fixedly installed on the bottom plate 21, and the positioning sleeve is located on the positioning plate 27 and the Between the seat 25; the positioning sleeve 210 is detachably installed on the positioning shaft sleeve.

[0090] The test clamping device 2 of this embodiment is used to clamp the threaded air supply adjustment valve. The bottom of the threaded air supply adjustment valve is cylindrical, and the bottom of the threaded air supply adjustment valve is placed in the positioning sleeve 210. And hold the threaded air supply adjustment valve and start the cylinder 23 at the same time, and clamp and fix the threaded air supply adjustment valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com