Automatic heat-preservation batch feeder for pig breeding

A feeder and pig technology, applied in applications, mixers, mixer accessories, etc., can solve problems such as blockage of the discharge port, reduction of quantitative discharge stability, and viscous feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

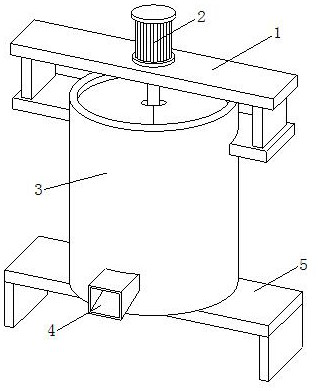

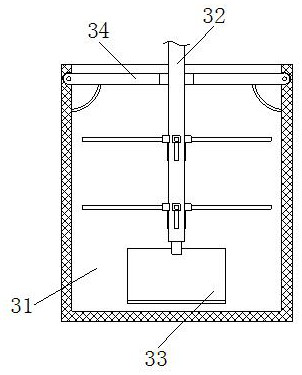

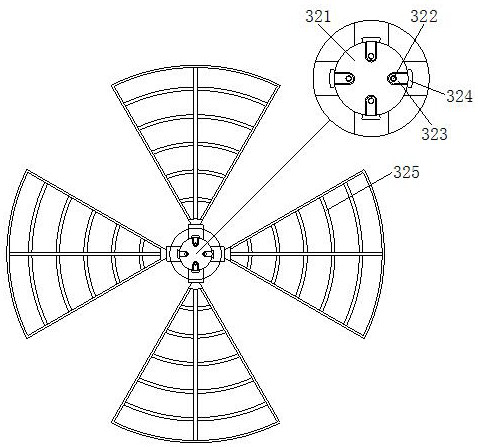

[0022] as attached figure 1 to attach Figure 5 Shown:

[0023] The present invention is an automatic thermal insulation feeder for pig breeding, the structure of which includes a support frame 1, a motor 2, a feeding host 3, a discharge port 4, and a support platform 5, and a motor 2 is fixedly installed on the top of the support frame 1. Frame 1 is welded on the outer side of the top of the feeding main machine 3, and the motor 2 is fixed to the upper end of the feeding main machine 3. The outer lower end of the feeding main machine 3 is embedded with a discharge port 4 and communicates with each other. The bottom of the feeding main machine 3 is welded on the support platform 5, the middle end of the top surface, the feeding host 3 includes a storage tube 31, a stirring mechanism 32, a discharge mechanism 33, and an opening and closing mechanism 34, the outer side of the upper end of the storage tube 31 is welded to the lower end of the support frame 1, and the stirring T...

Embodiment 2

[0030] as attached Figure 6 to attach Figure 7 Shown:

[0031] Wherein, the opening and closing mechanism 34 includes a sealing mechanism 341, a rotating shaft 342, and an elastic rod 343. The outer end of the sealing mechanism 341 is hinged to the inner wall of the container 31 through the rotating shaft 342. The lower end of the elastic rod 343 is welded to the container. Put the inner wall of the cylinder 31, the upper end of the elastic rod 343 runs through the inside of the sealing mechanism 341 with a clearance fit, the rotating rod 321 runs through the inner side of the sealing mechanism 341 with a clearance fit, the sealing mechanism 341, the rotating shaft 342 and the elastic rod 343 Both are provided with two, and are installed in a left-right symmetrical structure, which is beneficial to open and close the upper end of the storage tube 31, so that the air pressure inside the storage tube 31 can be changed to ensure that the feed is smoothly discharged from the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com