Magnetic steel sheet feeding mechanism

A magnetic steel sheet and material storage technology, which is applied in the field of magnetic steel sheet feeding mechanism, can solve problems such as increased production costs, motor quality problems, and magnetic steel sheet fragmentation, so as to improve production efficiency, reduce production costs, and achieve high assembly quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Because different batches of rotors may need to be inserted with different sizes and different types of magnetic steel sheets, while the same batch of rotors need to be inserted with the same size and different types of magnetic steel sheets, and different types of magnetic steel sheets contain a variety of For this reason, when different types and sizes of magnetic steel sheets need to be inserted, it is necessary to configure or replace the feeding turntable and feeding fixture corresponding to different types and sizes of magnetic steel sheets.

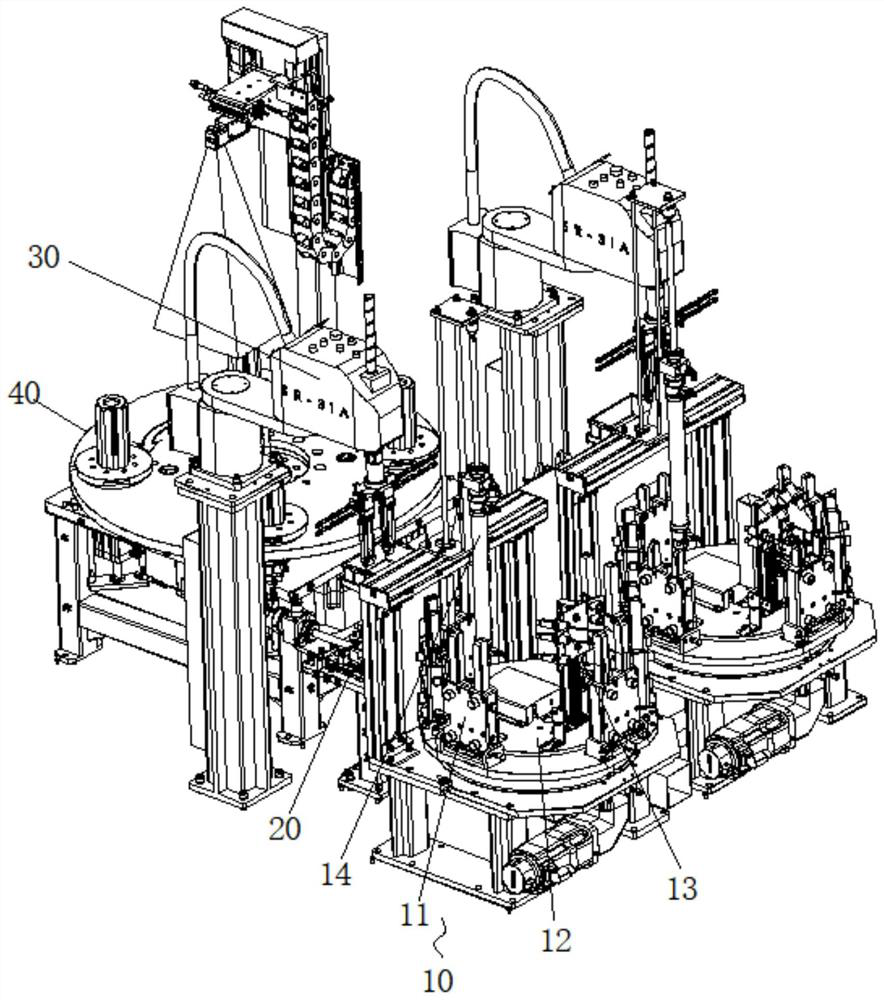

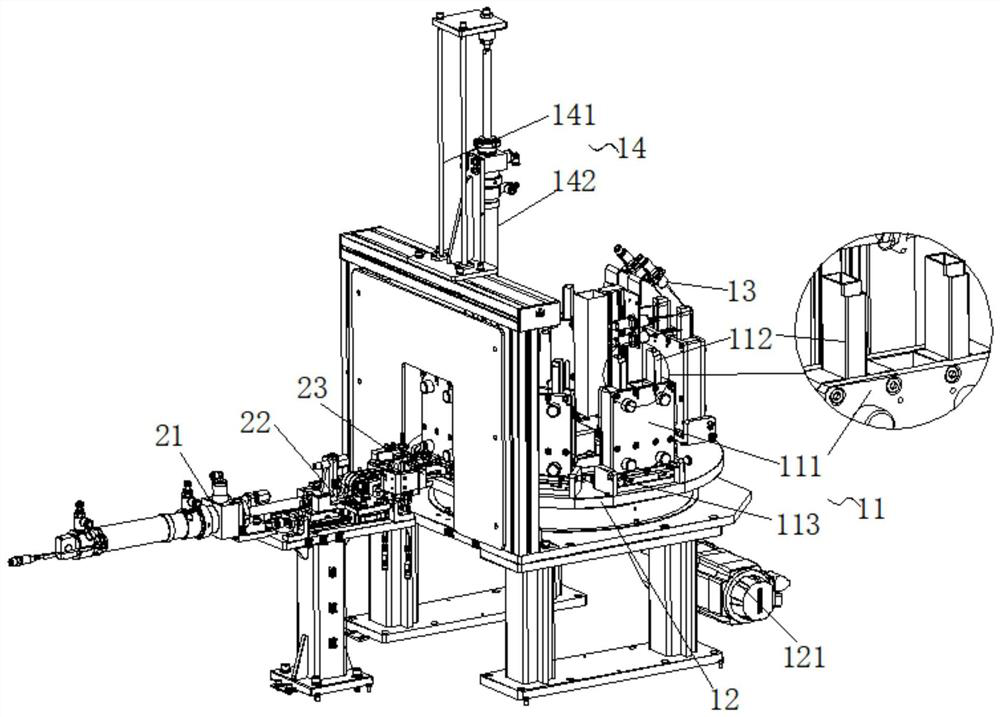

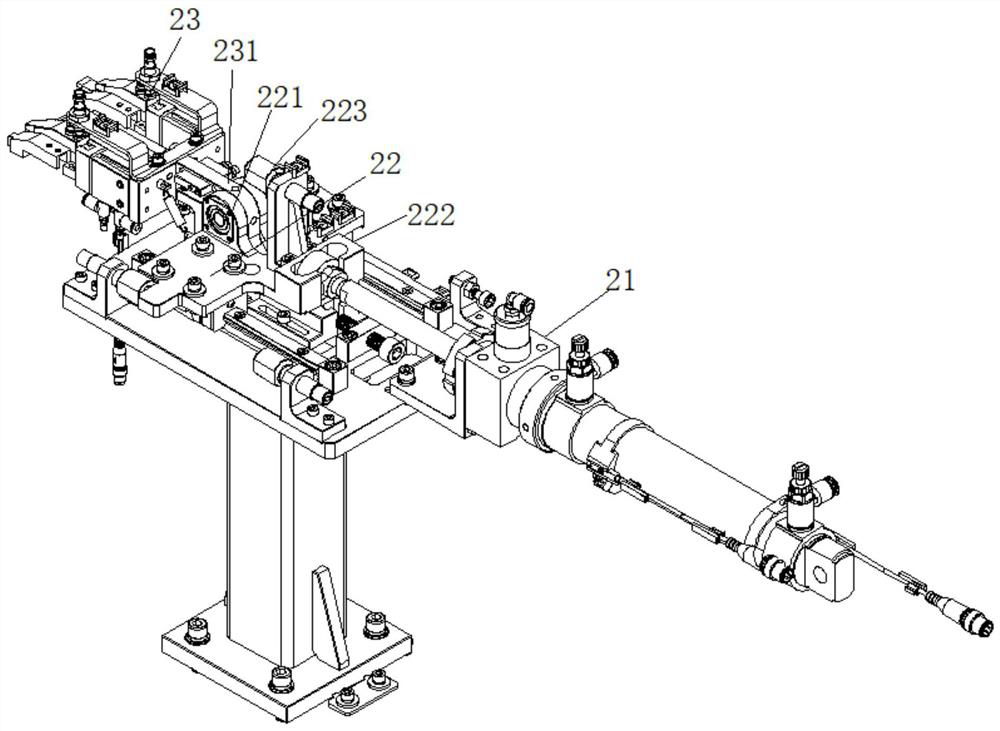

[0033] In order to solve the above technical problems, this embodiment provides a magnetic steel sheet feeding mechanism, such as figure 1As shown, it includes a feeding assembly 10 and a clamping assembly 20. The feeding assembly 10 includes at least one set of storage assemblies 11, and the storage assembly 11 is formed with a loading structure for accommodating different types and sizes of magnetic steel sheets, and then ...

Embodiment 2

[0046] This embodiment provides a magnetic steel sheet feeding mechanism, such as Figure 5 As shown, it also includes a feeding assembly 10, a clamping assembly 20, a pressing assembly 30 and a pressing platform 40. The feeding assembly 10 includes at least one set of storage assemblies 11, and the storage assembly 11 is formed for accommodating different The loading structure of the magnetic steel sheets of different sizes, and then realize the loading of magnetic steel sheets of different sizes through the loading structure on the material storage assembly 11. The clamping assembly 20 is arranged on the discharge side of the storage assembly 11, and is clamped The magnetic steel sheets on the storage assembly 11 are flipped and loaded, and the loading of different types of magnetic steel sheets can be assembled to different batches of rotors only through the storage assembly 11 when assembling the rotor, achieving compatibility with different types of rotors. The magnetic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com