Automatic feeding system for electrophoretic coating of conical sleeves and feeding process based on automatic feeding system

A technology of tapered casing and automatic feeding, which is applied in the direction of electrolytic coating, electrophoretic plating, coating, etc., can solve the problem of inability to automatically arrange the tapered casing, avoid the increase of labor cost, improve the alignment efficiency, The effect of meeting the requirements of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the techniques, creative features of the present invention, it is more clear and easy to understand, and the present invention is further illustrated in conjunction with the accompanying drawings and specific embodiments:

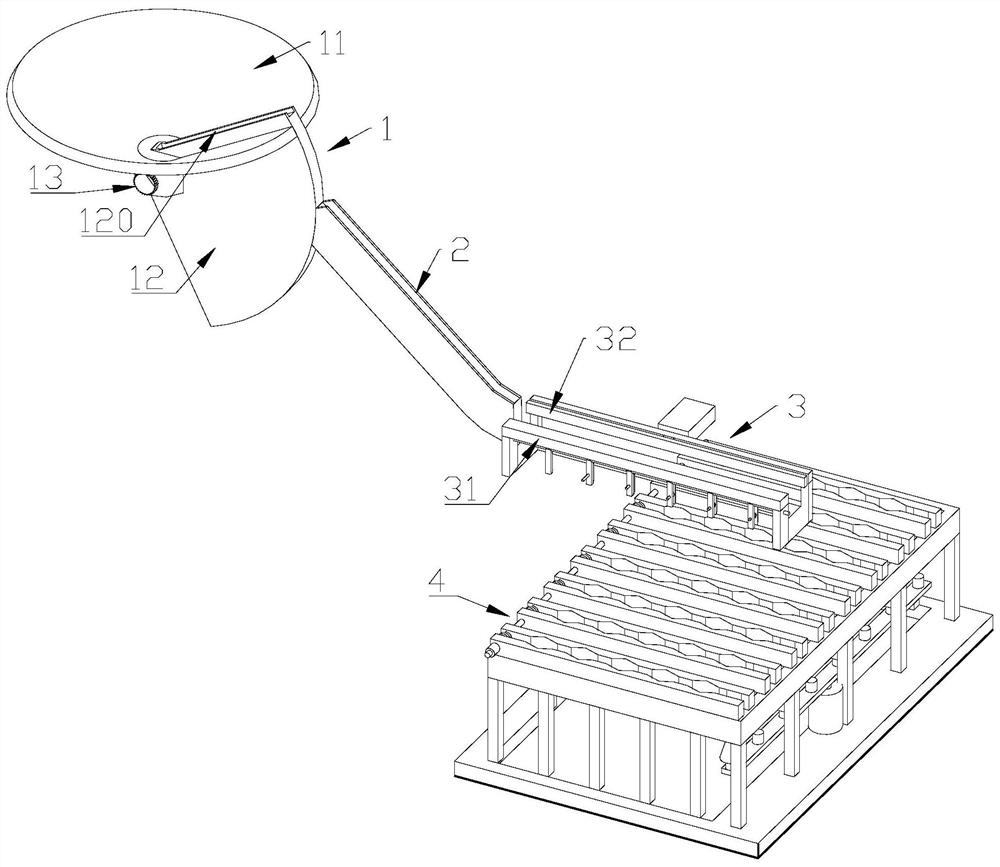

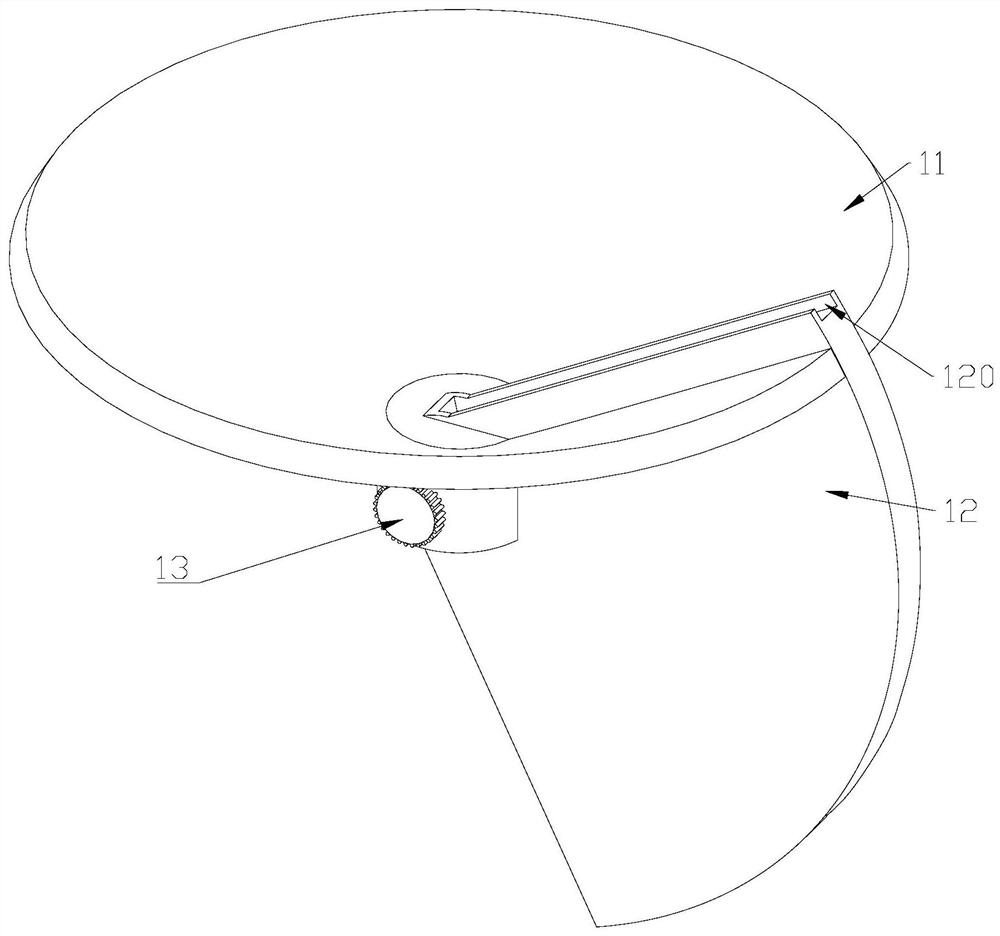

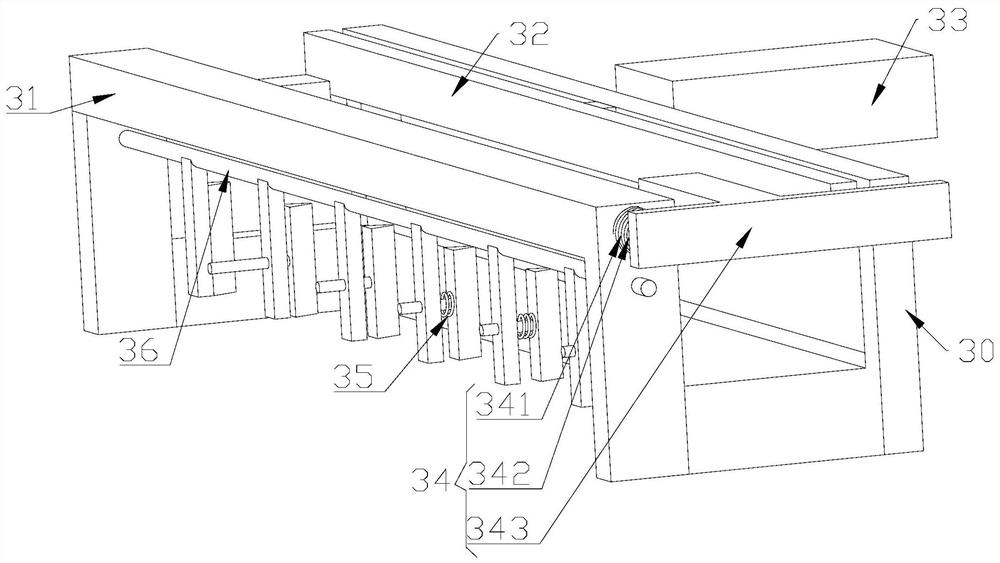

[0033] like Figure 1 to 6 As shown, the present invention first discloses a tapered casing electrophoretic painted automatic upper system, including: an automatic alignment device 1 for automatically arrangeing the tapered sleeve and outputs; intermediate rail 2, with vertical The angle between the direction is acute angle, and the intermediate rail 2 is in communication with the output of the automatic alignment device 1; the transfer disk 3 is used to undertake the tapered sleeve output from the low end output of the intermediate guide and make the adjacent cone sleeve. There is interval; and the output tray 4, which is used to undertake the tapered sleeve output from the transfer plate 3 and discharge the cone sleeve.

[0034] The aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com