Mobile rear unloading platform based on grain transportation

A mobile and food technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of no self-unloading ability, reduced labor intensity, and reduced labor costs, so as to save labor costs and reduce labor intensity , Improve the effect of unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

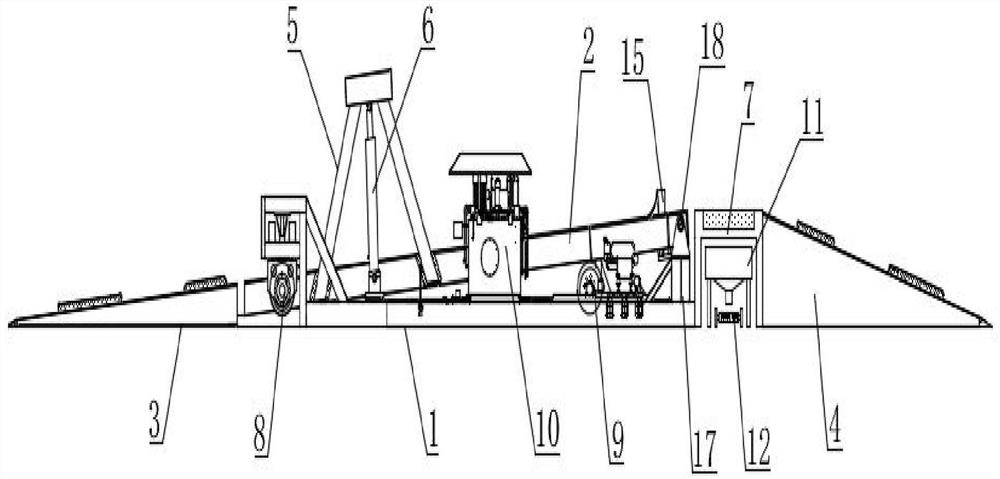

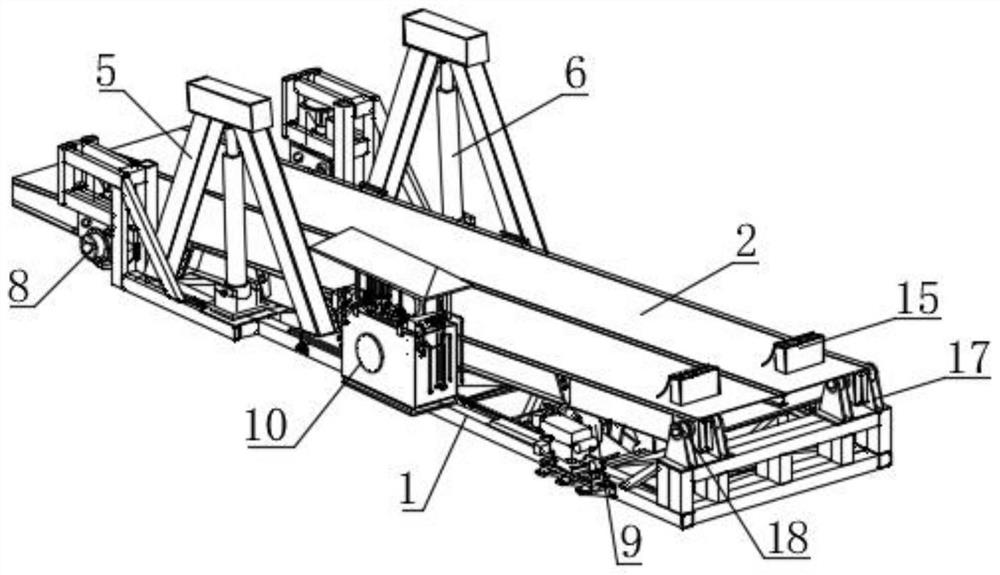

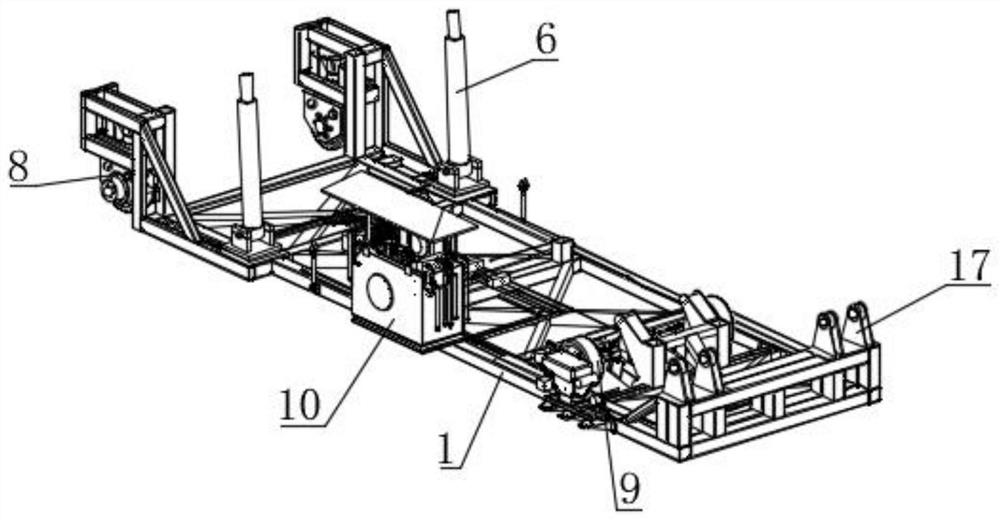

[0050] like Figure 1-9 As shown, the mobile rear unloading platform based on grain transportation proposed by the present invention includes an underframe 1, a flap 2, a first approach bridge 3, a second approach bridge 4 and a transition platform 7, and the first approach bridge 3 and the second approach bridge 4 are located at The two ends of the underframe 1, and the underframe 1 and the first approach bridge 3 are fixed by bolts (or connected by a articulated mode), and the transition platform 7 is connected by bolts to connect the underframe 1 and the second approach bridge 4 (or by articulated bridges). mode connection), the flap 2 is arranged above the underframe 1, and the end of the underframe 1 near the second approach bridge 4 is provided with a mounting seat 17, and one end of the flap 2 is rotationally connected with the mounting seat 17 through a flip shaft 18, and the flap The other end of 2 is equipped with herringbone frame 5, and the number of herringbone fr...

Embodiment 2

[0055] like Figure 7 and Figure 12 As shown, the difference between this embodiment and Embodiment 1 is that two sets of baffles 16 are installed on the top of the transition platform 7, and the setting of the two sets of baffles 16 not only plays a role in guiding the trucks driving in, but also makes the trucks Drive into the turning plate 2 smoothly, and help to make the falling grain enter the discharge port 703, prevent the grain from being spilled to both sides, and the two groups of baffle plates 16 are equipped with dust absorption processing assembly 13, dust absorption processing assembly 13 Comprise dust removal box 131, cross pipe 133, dust suction cover 134, dust suction pipe 135 and blower fan 136, two groups of baffle plates 16 opposite sides are equipped with cross pipe 133, and its connected dust suction cover 134 (or baffle) on cross pipe 133 Offer groove on the plate 16, horizontal pipe 133 and suction cover 134 are positioned at groove, avoid running int...

Embodiment 3

[0058] like figure 1 , Figure 10 and Figure 11 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that two sets of drive wheel assemblies 8 and two sets of steering wheel assemblies 9 are installed on the chassis 1, and the two sets of drive wheel assemblies 8 are symmetrical about the flap 2, Two groups of steering wheel assemblies 9 are symmetrical about the turnover plate 2, and the driving wheel assembly 8 is located at an end near the first approach bridge 3, and the steering wheel assembly 9 is located at an end near the second approach bridge 4; the driving wheel assembly 8 includes a first connecting frame 801, The driving wheel 802, the first jacking cylinder 803 and the connecting plate 804, the first connecting frame 801 is fixedly installed on the underframe 1 by bolts, and one side of the first connecting frame 801 is a triangular bracket, and the first jacking cylinder 803 is set On the first connecting frame 801 and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com