Wear-resisting ball heat treatment device

A technology of heat treatment devices and wear-resistant balls, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as low efficiency, troublesome loading and unloading, etc., and achieve the effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

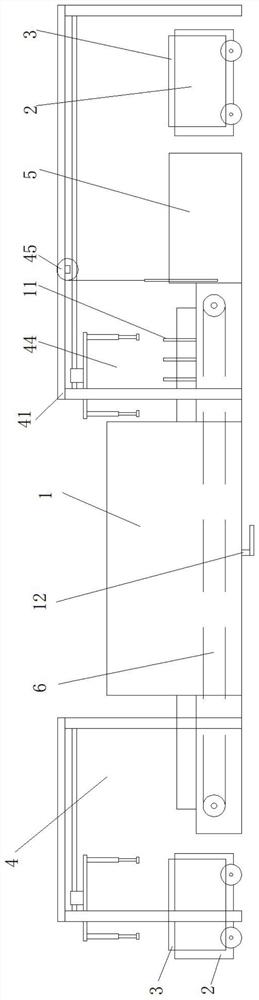

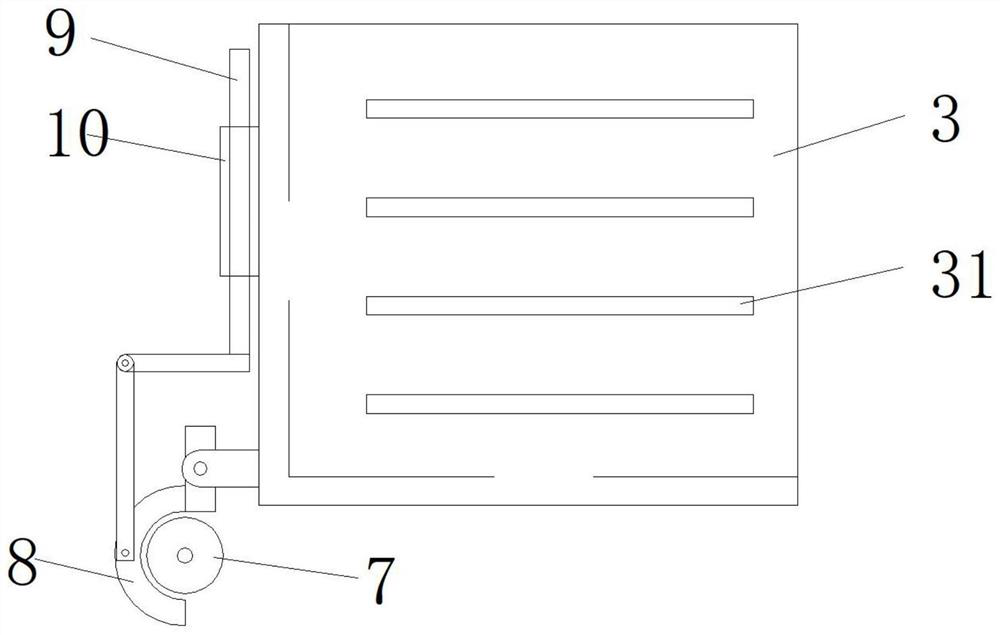

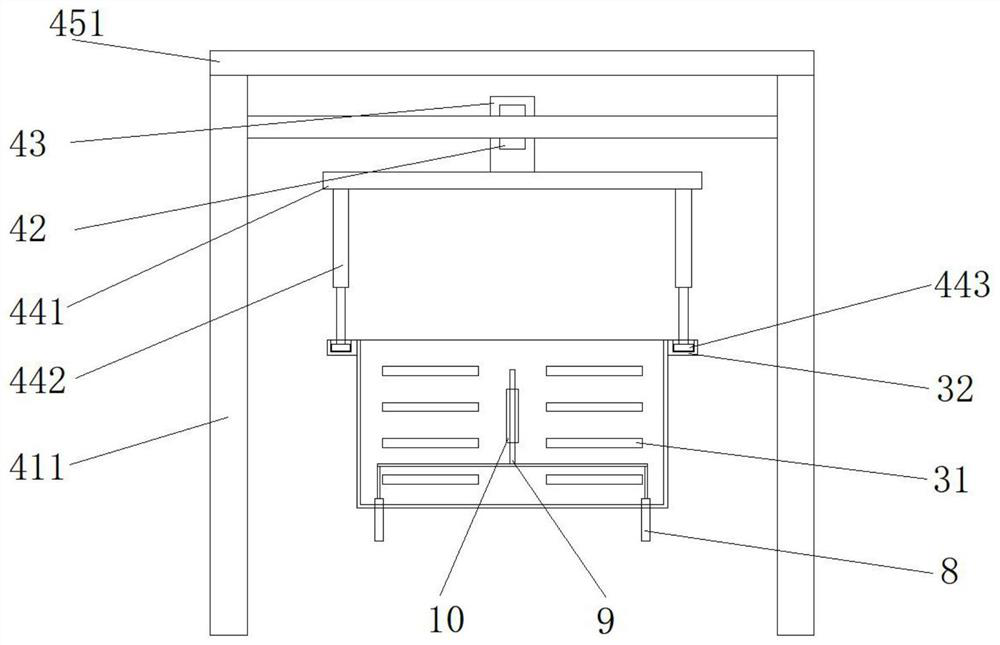

[0023] figure 1 The specific embodiment of the present invention is shown: a heat treatment device for wear-resistant balls, including a heat treatment furnace 1 and a material transport trolley 2, the material transport trolley 2 is provided with a storage basket 3, the material transport trolley is convenient for transportation, and the cast resistance The grinding balls are placed in the holding basket. The feed port and the discharge port of the heat treatment furnace 1 are respectively provided with a retrieving mechanism 4, and the discharge port of the heat treatment furnace 1 is also provided with a water-cooled box 5, and the water-cooled box 5 is provided on one side of the loading basket 3 entrances. There is a gate 51, and the retrieving mechanism 4 on the side of the discharge port is provided with a lifting device 45 corresponding to the valve 51. The water cooling box 5 is provided with a chute on both sides of the position of the gate 51, and the gate 51 moves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com