Cloth sewing and cutting equipment

A fabric and sewing technology, applied in the field of fabric sewing and cutting equipment, can solve the problems of low fabric efficiency and quality, and achieve the effects of avoiding manual errors, reducing manual processing steps, and improving processing production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

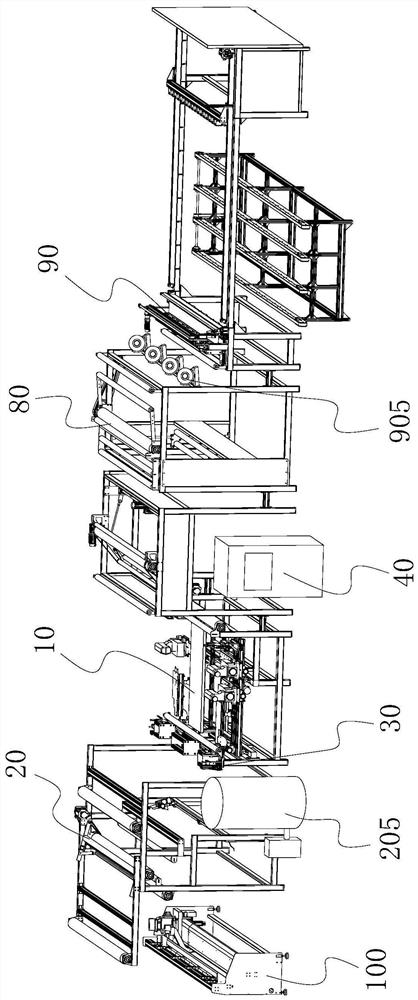

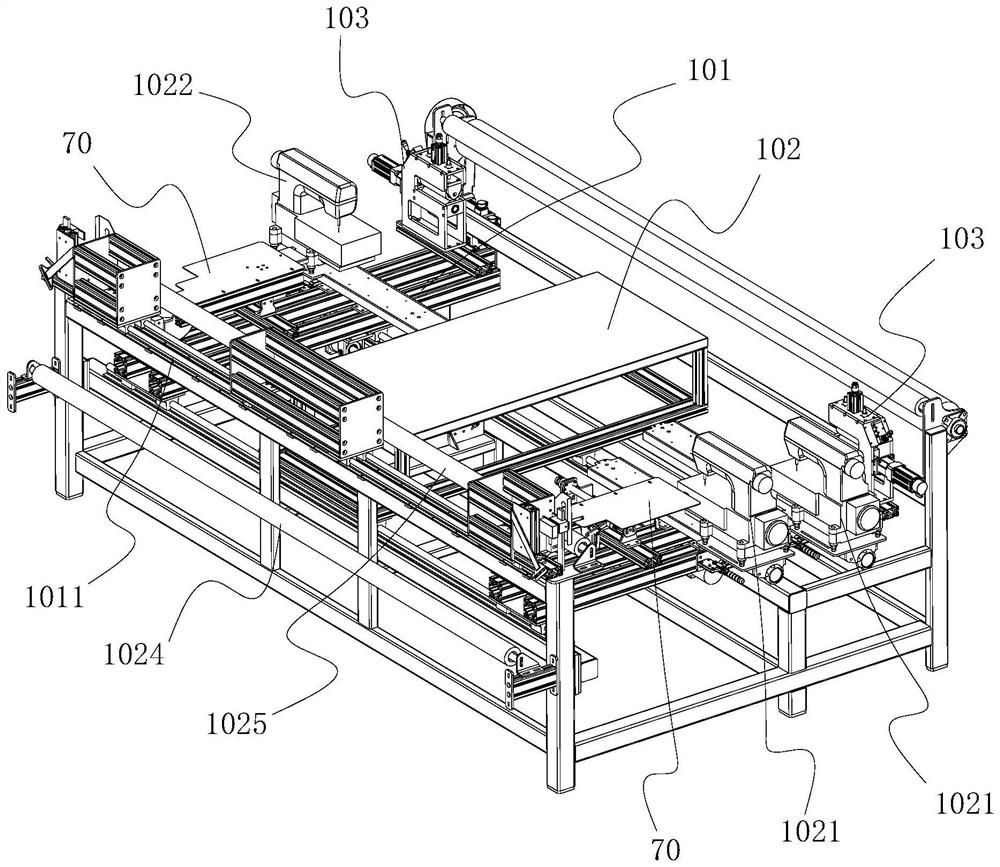

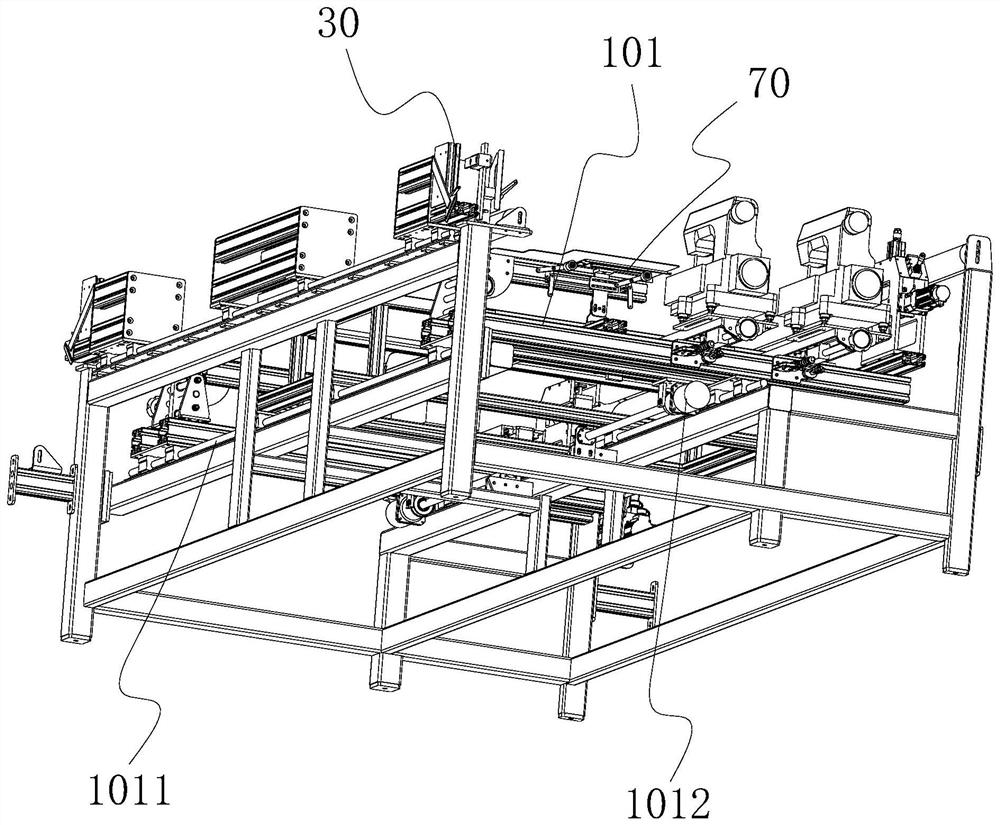

[0049] Please refer to Figure 1 to Figure 18 As shown, the present embodiment provides a cloth sewing and cutting device, including a sewing mechanism 10 , a feeding frame 20 , a material storage frame 80 , a cloth cutting mechanism 90 , a cloth splicing machine 100 , a quality detector 110 and a control center 40 . When in use, the cloth is conveyed through the feeding frame 20, and the suction edge alignment and cutting of the cloth are completed, and the cloth is cut into cloth of uniform width. Moreover, two rolls of cloth can be sewn by the cloth splicing machine, avoiding the problem of manual loading of the feeding frame 20, and improving the efficiency of cloth processing. Furthermore, the cloth is hemmed and sewn by the sewing mechanism 10, so as to avoid thread running or thread breakage at the edge of the cloth, and improve the aesthetics of the cloth. After the sewing is completed, the cloth is stored through the material storage rack 80 and delivered to the clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com