Large-section wide-span rigid frame bridge swivel beam construction monitoring method and monitoring device

A technology for monitoring devices and large segments, which is applied in the direction of measuring devices, bridges, bridge construction, etc., to achieve the effects of improving position correction efficiency, increasing intelligence, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

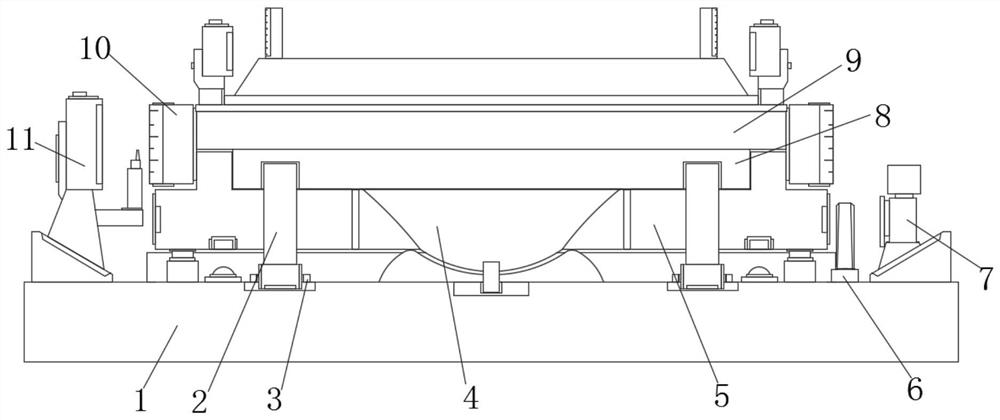

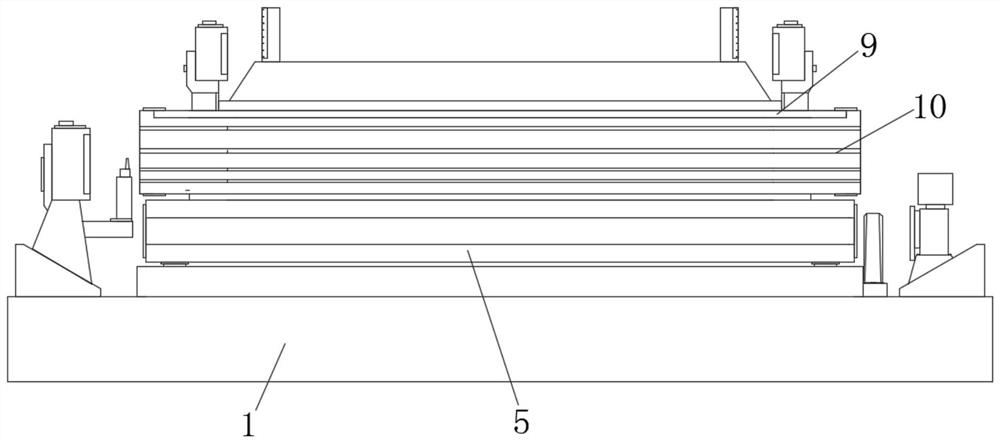

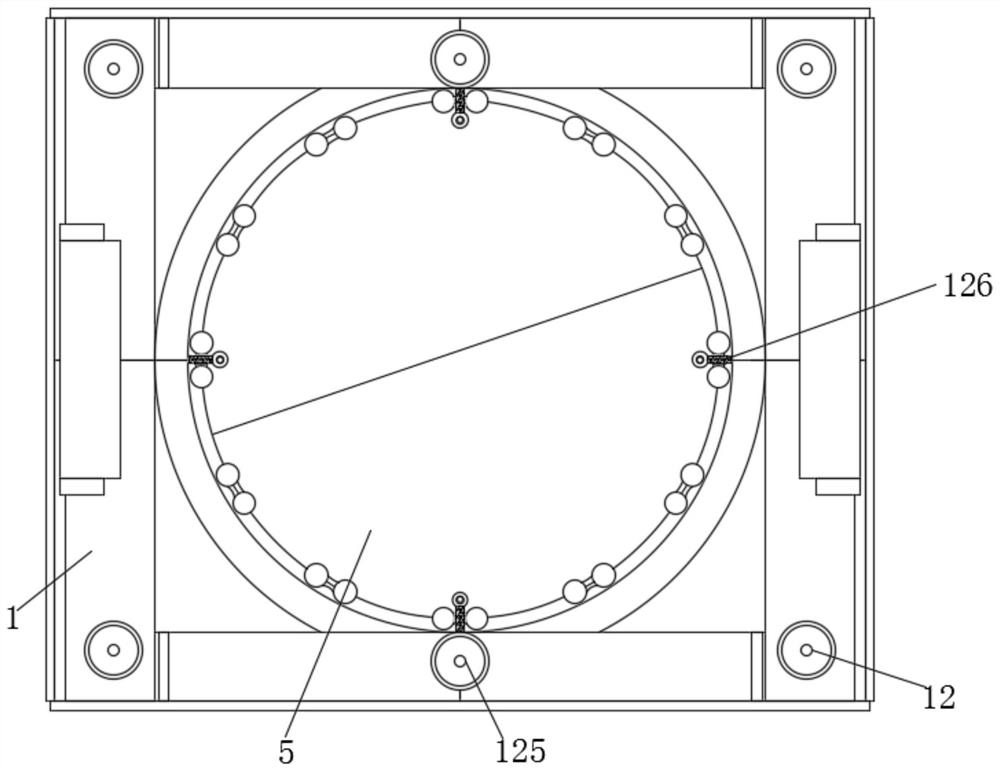

[0040] Example 1, such as Figure 1-2 As shown, through the observation cooperation of three sets of elevation observation points installed on the cantilever on the upper part of the swivel body, four sets of tower rulers and two leveling instruments, the whole process of swivel body can be monitored. The center line of the total station is used to correct the body position, and the deviation of the center line is allowed to be no more than 2cm, which is convenient for the measurement personnel to report the data obtained to the measurement and control personnel in time until the deviation requirements are met.

Embodiment 2

[0041] Example 2, such as Figure 1-5 As shown, utilizing the mutual cooperation of the second total station 11 and the swivel scale mark 10, the axis rotation angle of the swivel and the height measurement and the distance of the rotation can be monitored respectively, so that it is convenient to pass the second total station 11 and the swivel body. The scale mark 10 can control the tracking and monitoring of the rotation smoothly, and improve the monitoring efficiency and correction processing of the abnormal change of the rotation.

[0042] Working principle: When the monitoring device is in use, as the upper bearing platform 5 rotates on the lower axis with the cooperation of the ball hinge 4, the upper bearing platform 5 drives multiple sets of legs 2 to rotate under the guidance of the slideway bracket 3, and at this time The 360° prism 6 can be used to correspond to the structure of the first total station 7, and the plane observation and elevation observation can be ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com