House building concrete pouring workbench

A concrete and workbench technology, which is applied in construction, building structure, and building material processing, can solve problems affecting the quality of concrete pouring and segregation of concrete, so as to ensure the quality of pouring, improve the quality of construction, and ensure cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following is attached Figure 1-4 The application is described in further detail.

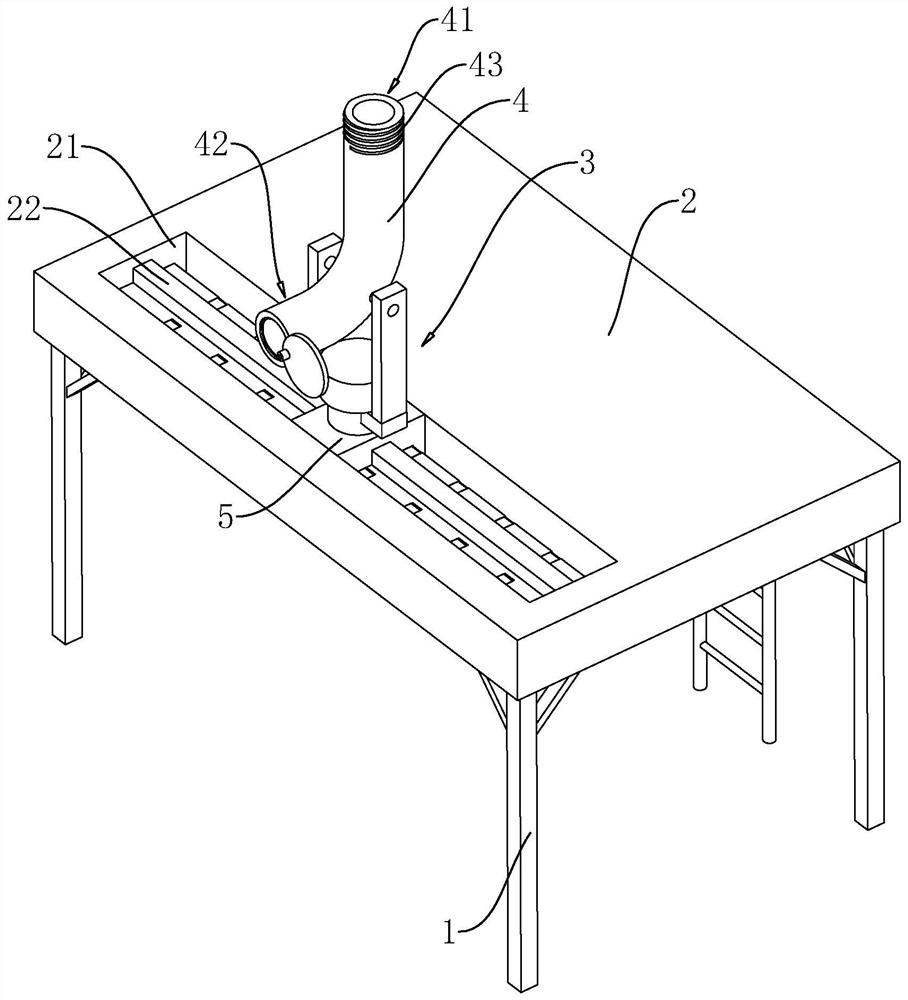

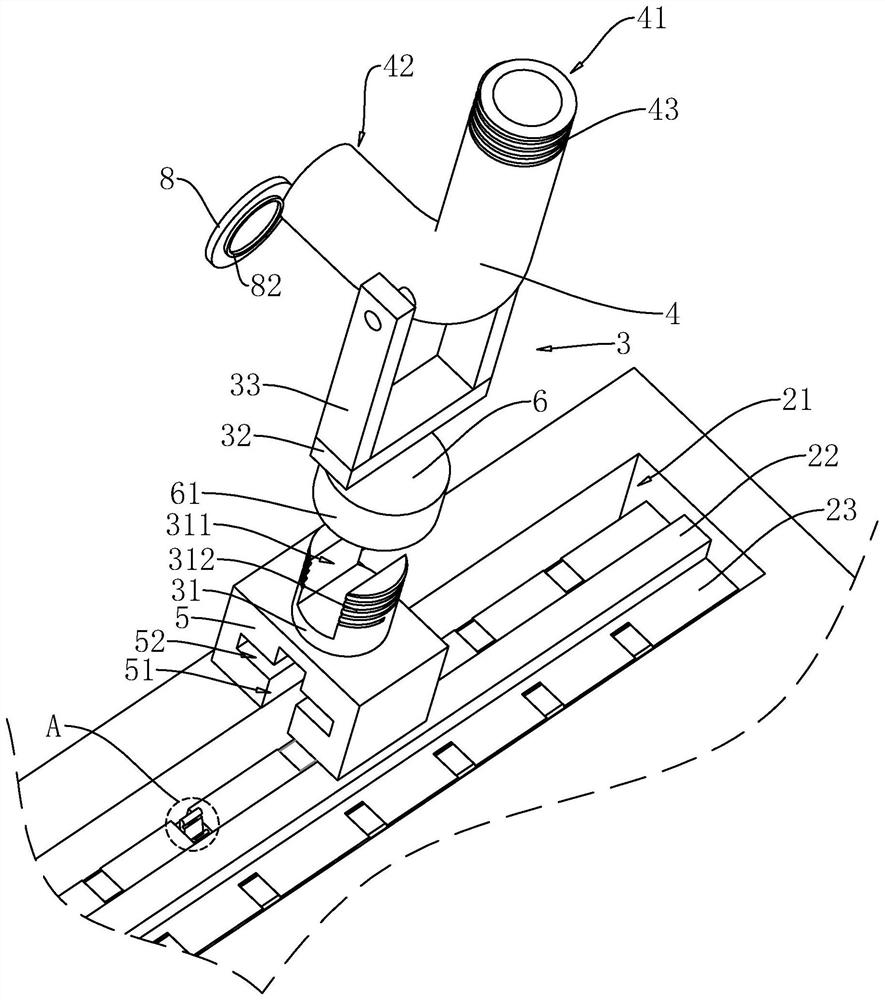

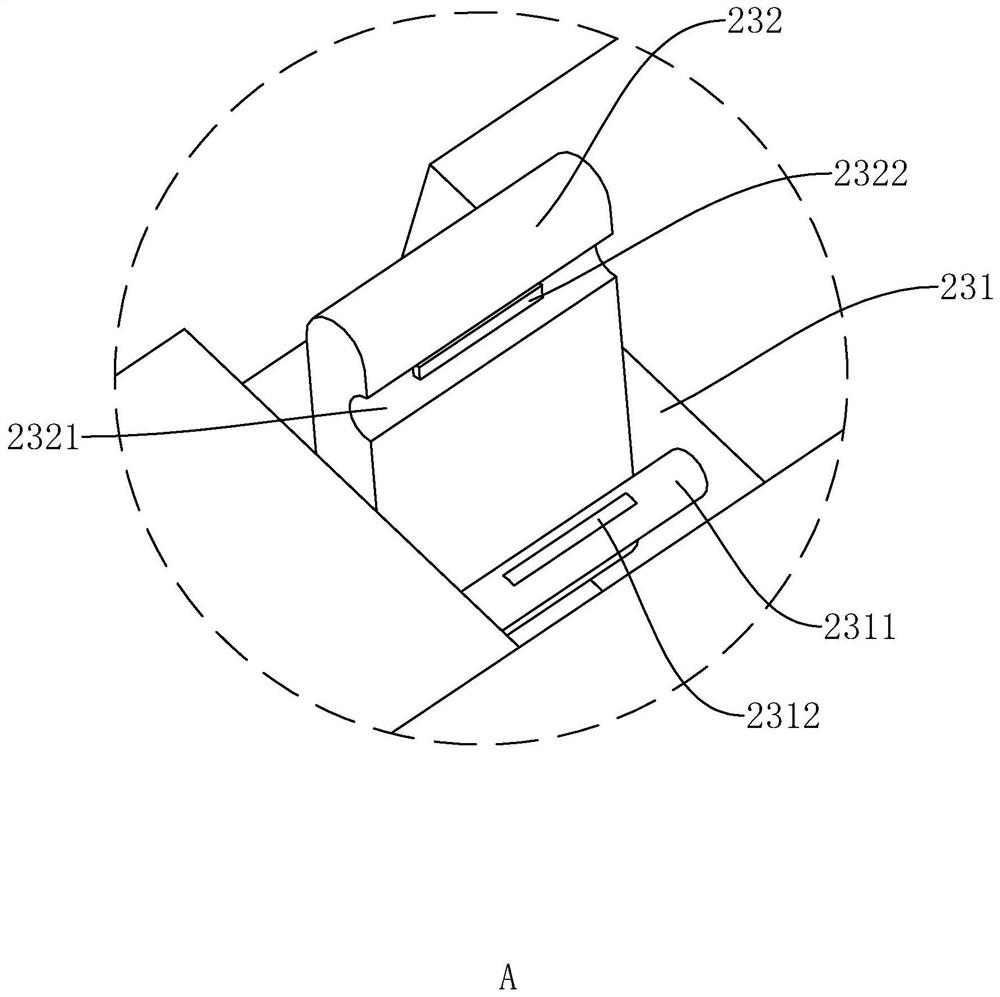

[0033] The embodiment of the present application discloses a building concrete pouring workbench. refer to figure 1 , figure 2 , including a support frame 1 and a rectangular support plate 2 fixedly connected to the upper end surface of the support frame 1 . The upper end surface of the support plate 2 is slidingly connected with a mounting frame 3, and one end of the mounting frame 3 away from the support plate 2 is rotatably connected with a connecting pipe 4, and one end of the connecting pipe 4 is a feed end 41 for inserting a material pipe for conveying concrete. One end is the discharge end 42 for concrete discharge. When pouring concrete, the material pipe is inserted into the feeding end 41 of the connecting pipe 4, the material pipe discharges the concrete into the connecting pipe 4, and then the concrete is discharged to the concrete pouring layer from the discharging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com