Differential humidity sensor based on substrate integrated waveguide doublere-input resonant cavities

A substrate-integrated waveguide and humidity sensor technology, applied in the field of sensors, to achieve the effect of improving sensing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to better describe the design process and purpose, the present invention will be further described below in conjunction with the embodiments and accompanying drawings:

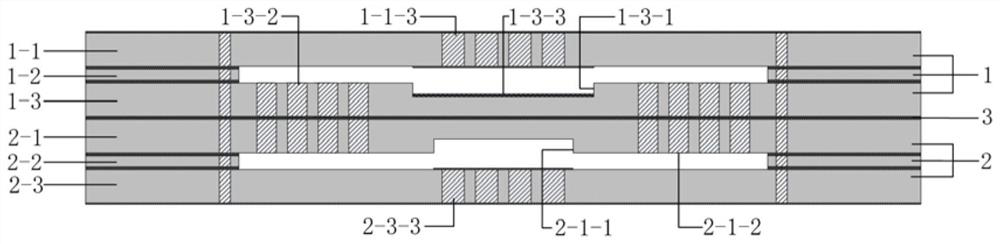

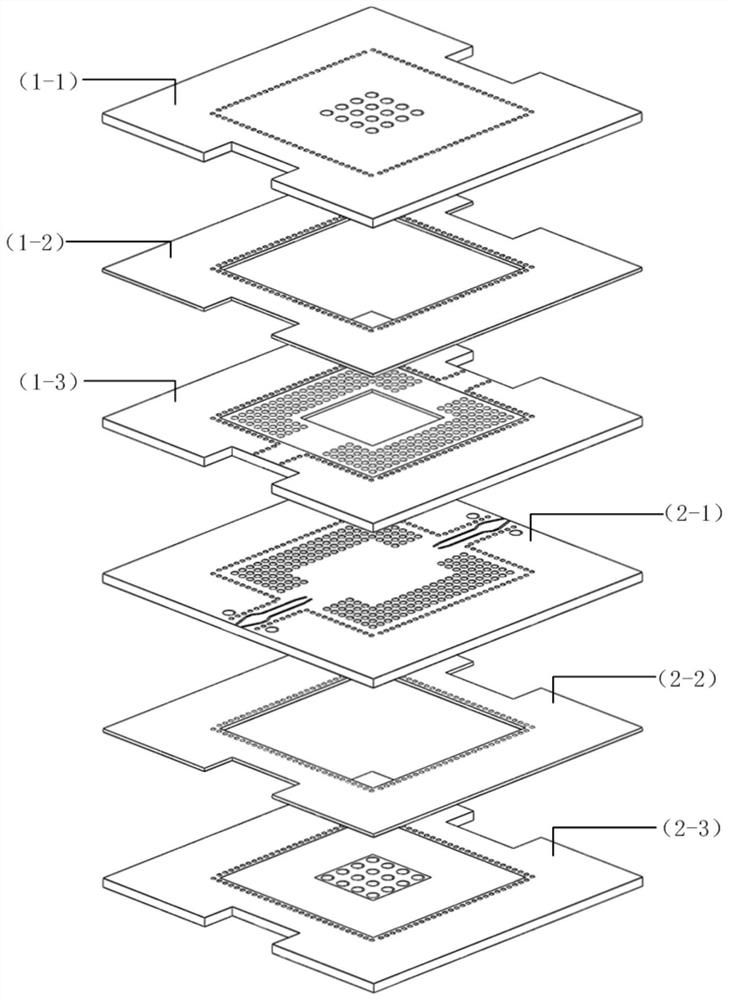

[0039] Such as figure 1 As shown in Figure 7(a) and Figure 7(b), the differential humidity sensor based on the substrate-integrated waveguide dual-entry resonant cavity proposed by the present invention includes two resonant cavities stacked up and down and two sections of "coplanar waveguide + strip shape line" feeder (3).

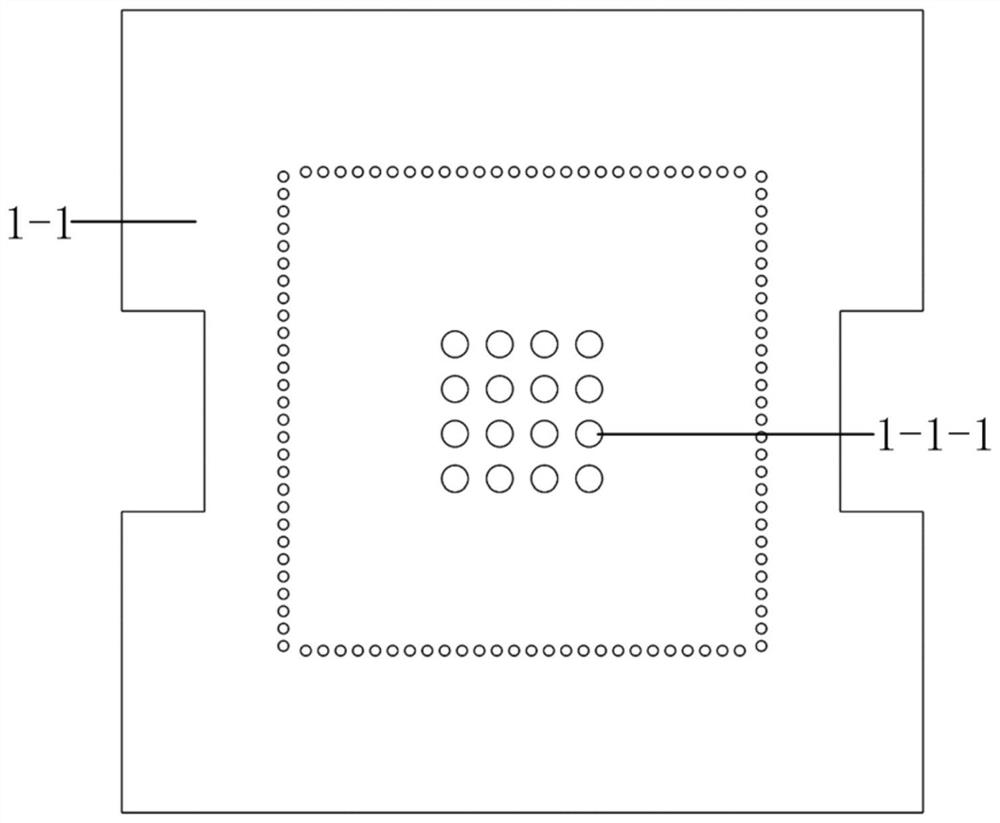

[0040] The upper resonance cavity (1) is composed of an upper dielectric substrate (1-1), an intermediate dielectric substrate (1-2) and a lower dielectric substrate (1-3). The lower resonance cavity (2) is composed of an upper dielectric substrate (2-1), an intermediate dielectric substrate (2-2) and a lower dielectric substrate (2-3). Each dielectric substrate has a three-layer structure of a top metal layer, an intermediate dielectric layer and a bottom metal layer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com