Large-scale road maintenance machinery network control system and design method thereof

A technology of large-scale road maintenance machinery and network control system, applied in the field of railway construction machinery, can solve the problems of low cost performance of hardware, high cost of expanding input and output points, complicated secondary construction of system network structure, etc. The effect of topology expansion, solving communication rate bottlenecks and communication delay problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

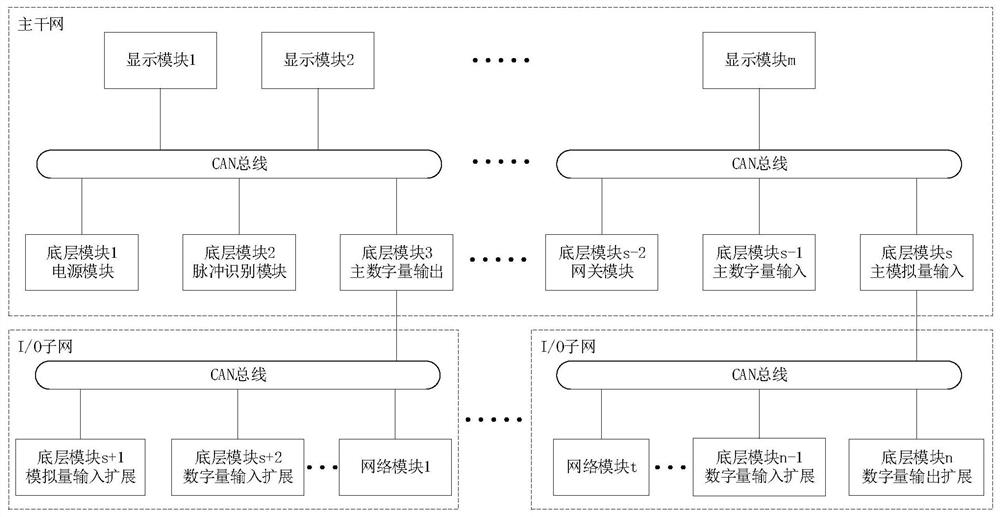

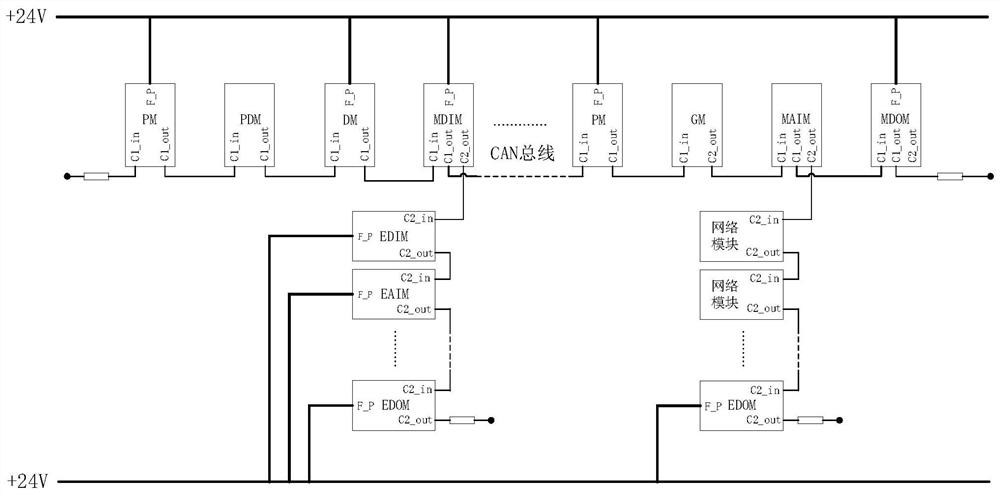

[0101] as attached Figure 4 As shown, an embodiment of the large-scale road maintenance machinery network control system of the present invention specifically includes: a main control module 1, a centralized control module 2, a display module 3, an Ethernet switch 4, and several I / O modules. The train-level network is composed of the main control module 1, the centralized control module 2, the display module 3 and the Ethernet switch 4. The in-vehicle network is composed of the main control module 1, the centralized control module 2 and the display module 3, or the main control module 1, the centralized control module 2, the display module 3 and the Ethernet switch 4. The I / O sub-network is composed of the main control module 1, the centralized control module 2 and several I / O modules (which may specifically include modules such as AIM, AOM, DIM, and DOM). A three-level control network is composed of a train-level network, an in-vehicle network, and an I / O sub-network to rea...

Embodiment 2

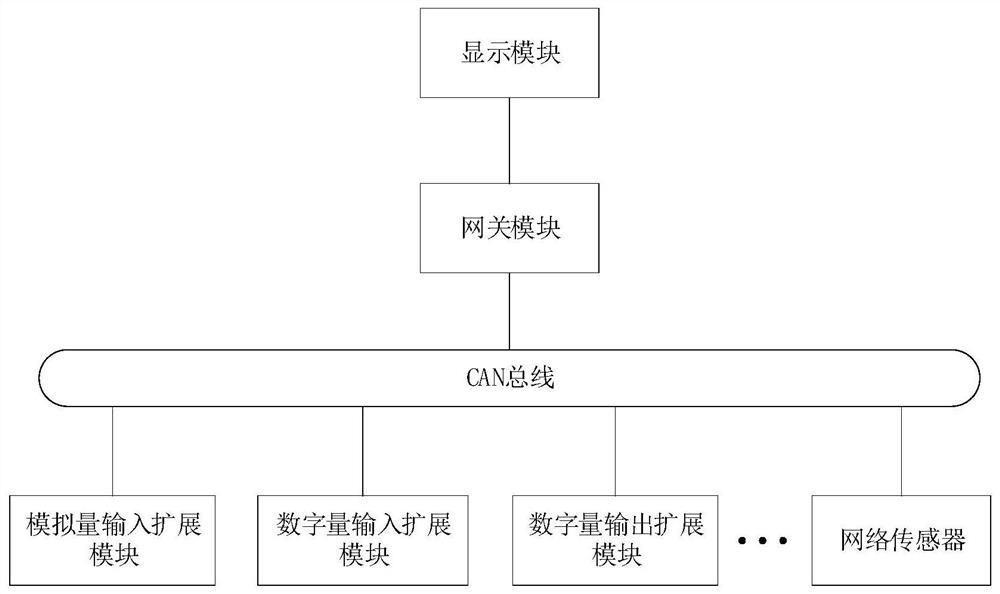

[0118] as attached Figure 5 As shown, another embodiment of the large-scale road maintenance machinery network control system of the present invention specifically includes: a main control module 1, a display module 3, an Ethernet switch 4, and several I / O modules. The train-level network is composed of the main control module 1, the display module 3 and the Ethernet switch 4. The in-vehicle network is composed of the main control module 1 and the display module 3, or the main control module 1, the display module 3 and the Ethernet switch 4. The I / O sub-network is composed of the main control module 1 and several I / O modules. A three-level control network is composed of a train-level network, an in-vehicle network, and an I / O sub-network to realize decentralized control of the running and operating functions of large-scale road maintenance machinery.

[0119] The main control module 1 serves as the core of the entire large-scale road maintenance machinery network control sy...

Embodiment 3

[0124] as attached Figure 6 As shown, the third embodiment of the large-scale road maintenance machinery network control system of the present invention specifically includes: a centralized control module 2, a display module 3, an Ethernet switch 4, and several I / O modules. The train-level network is composed of the centralized control module 2, the display module 3 and the Ethernet switch 4. The in-vehicle network is composed of the centralized control module 2 and the display module 3, or the centralized control module 2, the display module 3 and the Ethernet switch 4. The I / O sub-network is composed of the centralized control module 2 and several I / O modules. A three-level control network is composed of a train-level network, an in-vehicle network, and an I / O sub-network to realize decentralized control of the running and operating functions of large-scale road maintenance machinery.

[0125] The centralized control module 2 is the core of the network control system of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com