Automobile accessory industry supply chain intelligent replenishment system and warehouse thereof

A replenishment system and supply chain technology, applied in the supply chain intelligent replenishment system of the auto parts industry and its warehouses, can solve the problems of time-consuming, labor-intensive, high cost, low efficiency, etc., to reduce the number of days of inventory turnover and reduce out-of-stock rate index and the effect of reducing the error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

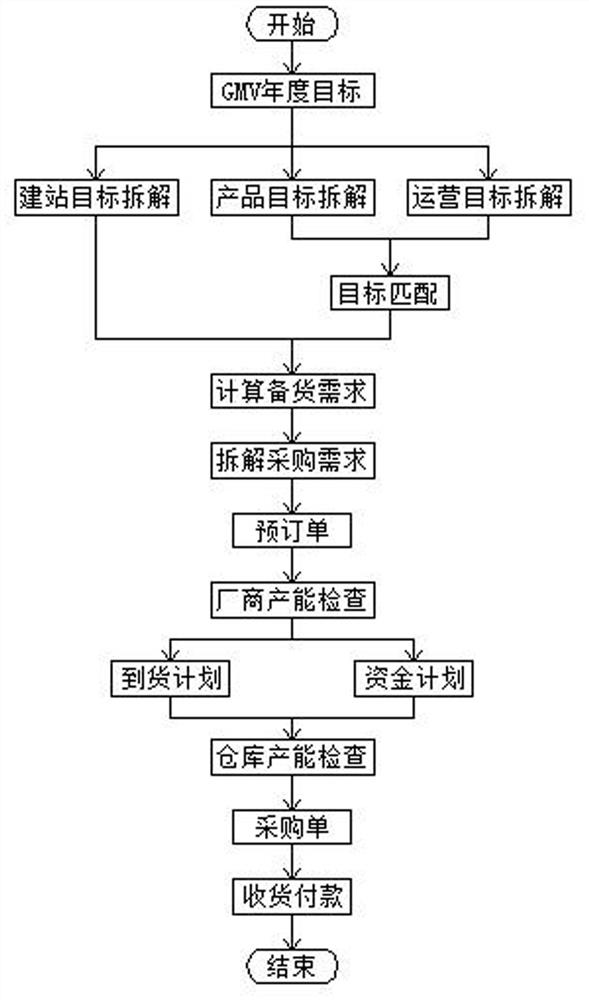

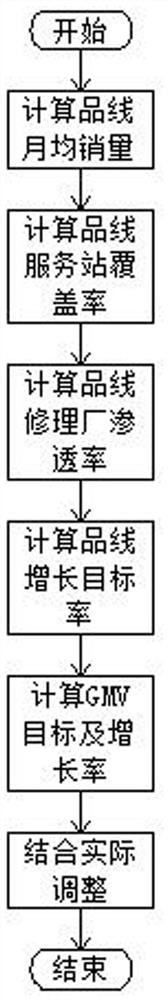

[0029] Such as Figure 1-5 As shown, an intelligent replenishment system for the supply chain of the auto parts industry is used to unify the supplier files, material files, safety stocks, sales forecast logic, transfer plan logic, and warehouse index monitoring involved in intelligent replenishment in the supply chain. Systematic management, as follows:

[0030] (1) Supplier files. The basis for smart replenishment is to sort out and systematically manage the supplier’s basic files, including basic information of suppliers, delivery dates of suppliers, starting quantities of suppliers, minimum order quantities of SKUs, and logistics Whether the fee is borne by the manufacturer, etc.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com