Driving backboard, display panel and manufacturing method of driving backboard

A technology for driving backplanes and substrates, which is applied in the field of display panels and display panel production and driving backplanes, can solve the problems affecting the driving effect of the driving backplane, the high impedance of the second conductive layer, and the limitation, so as to improve the driving effect and reduce the The effect of self-impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

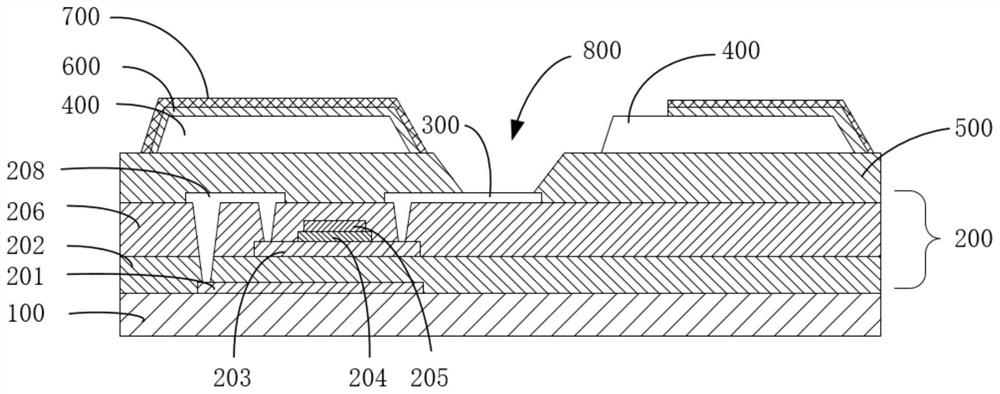

[0046] See figure 1 and combine figure 2 , the main body of this embodiment is a driving backplane, which is used to drive the light-emitting component 900. In this embodiment, the driving backplane includes:

[0047] Substrate 100;

[0048] A thin film transistor layer 200, the thin film transistor layer 200 is disposed on the substrate 100, and the thin film transistor layer 200 includes a source and drain metal layer 208;

[0049] The first conductive layer 300 and the second conductive layer 400, the first conductive layer 300 and the second conductive layer 400 are arranged on the substrate 100, the first conductive layer 300 is electrically connected to the source and drain metal layer 208 connection, the first conductive layer 300 is used to electrically connect to the positive pole of the light emitting component 900, the second conductive layer 400 is used to electrically connect to the negative pole of the light emitting component 900, and the first conductive lay...

Embodiment 2

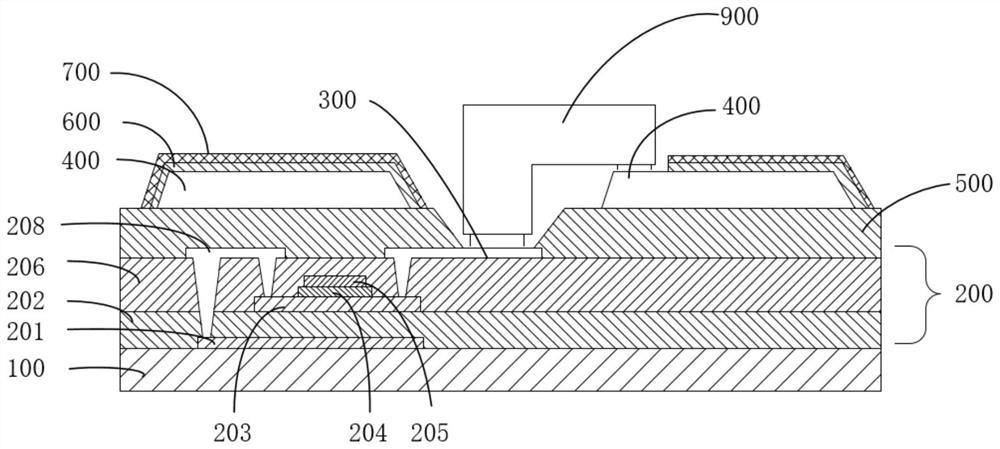

[0072] See figure 2 , this specific embodiment also provides a display panel as Example 2, the display panel provided in Example 2 includes a light-emitting component 900, and also includes a driving backplane as described in Example 1, and the light-emitting component 900 has A positive electrode connection end and a negative electrode connection end, the positive electrode connection end is electrically connected to the first conductive layer 300 , and the negative electrode connection end is electrically connected to the second conductive layer 400 .

[0073] Wherein, the above-mentioned light-emitting component 900 is specifically a MicroLED chip, and implementers can also replace the above-mentioned MicroLED chip with a MiniLED chip or an organic light-emitting diode.

Embodiment 3

[0075] Please combine Figure 3 to Figure 11 , this specific embodiment also provides a method for manufacturing a drive backplane, comprising the steps of:

[0076] providing a substrate 100;

[0077] A thin film transistor layer 200 is formed on the substrate 100, and a first conductive layer 300 for electrically connecting the anode of the light-emitting component 900 and a first conductive layer 300 for electrically connecting the cathode of the light-emitting component 900 are arranged on the thin film transistor. Two conductive layers 400, wherein the first conductive layer 300 and the second conductive layer 400 are arranged in different layers.

[0078] Wherein, on the substrate 100, a thin film transistor layer 200, a first conductive layer 300 for electrically connecting the anode of the light-emitting component 900, and a second conductive layer 400 for electrically connecting the cathode of the light-emitting component 900 are fabricated, specifically Include ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com