Wear-resistant waterline hoisting fixing seat with elastic buffering performance

An elastic buffering and fixing seat technology, applied in the field of livestock breeding, can solve the problems of unfavorable water basket hanging line sliding and pulling, inconvenience, and easy damage to the hoisting and fixing seat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and advantages of the present invention more clearly understood, the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only for explaining the present invention, not for The invention is limited.

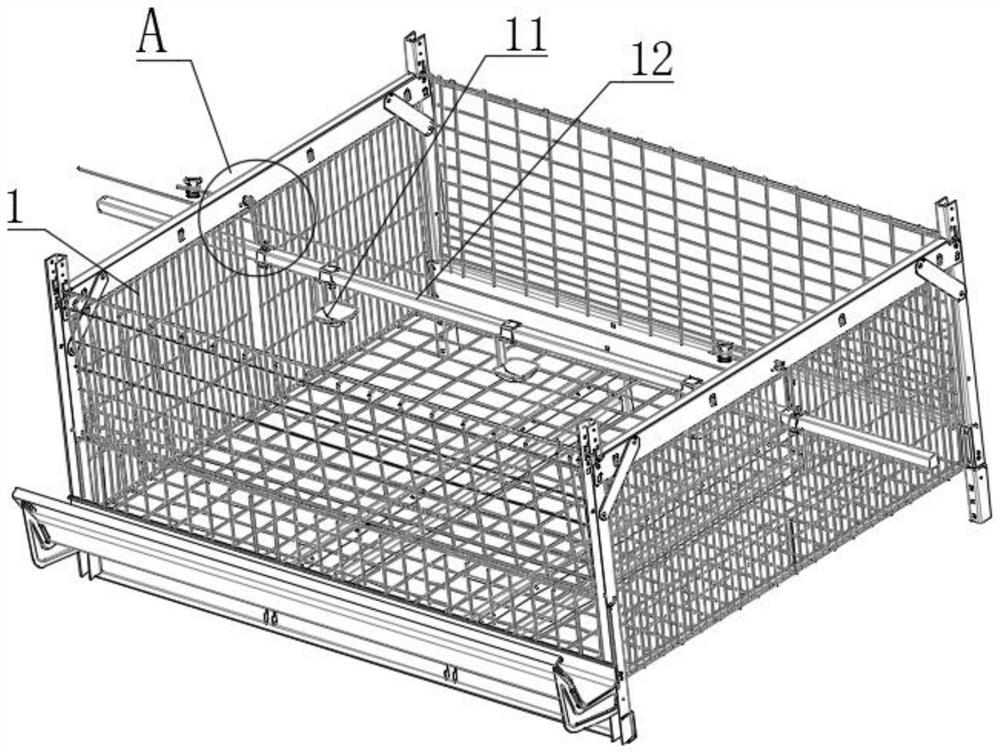

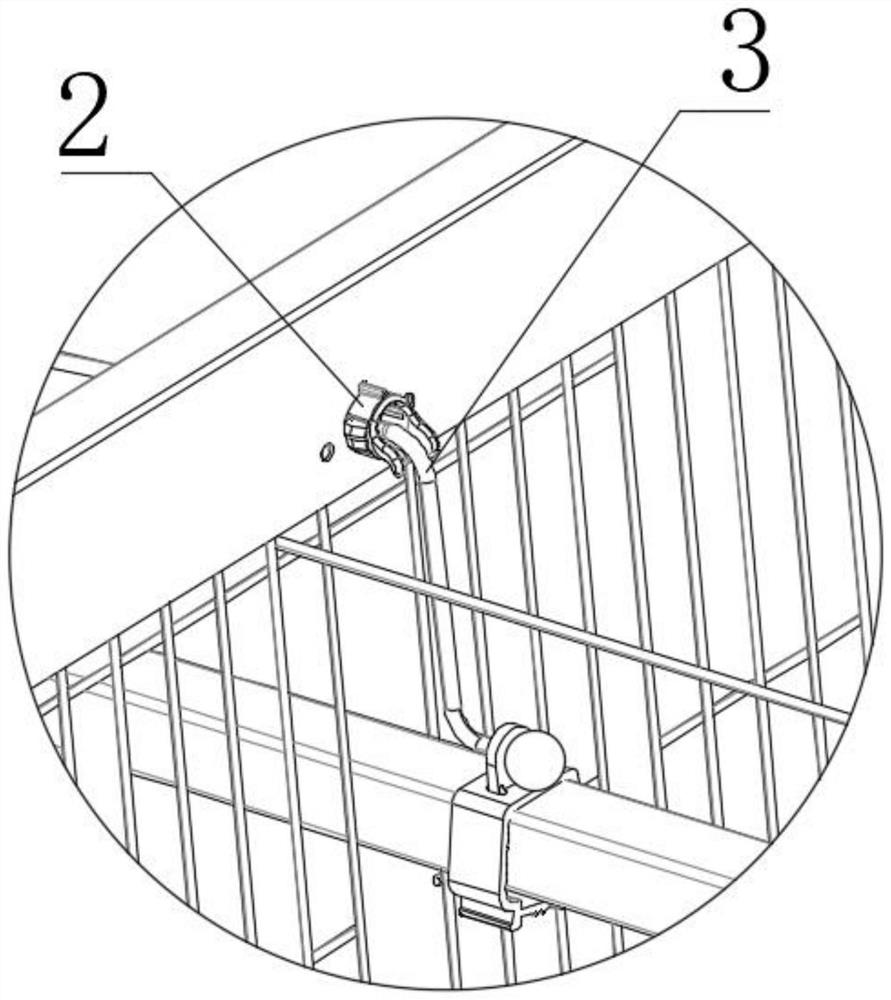

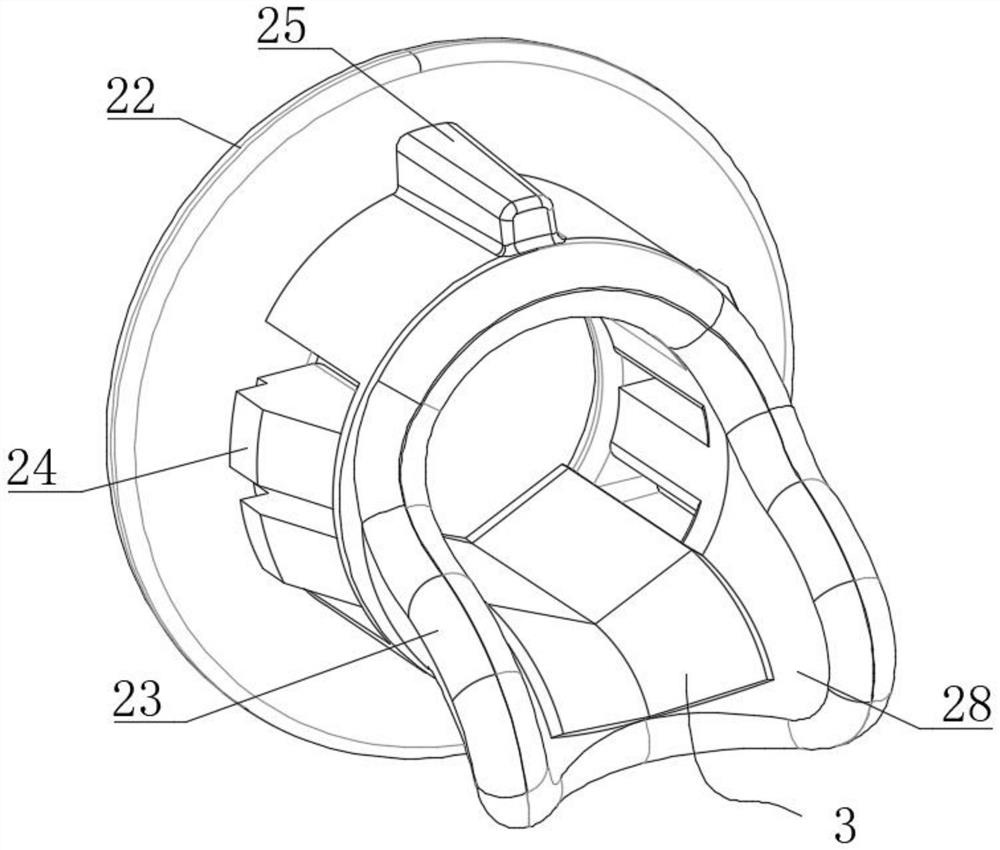

[0026] see figure 1 , figure 2 , image 3 and Figure 5 , the present invention provides a wear-resistant waterline hoisting mount with elastic buffer performance, the wear-resistant waterline hoisting mount with elastic buffer performance includes a support pipe part 21, 21 the clamping portion 24 around the outer wall;

[0027] The left end surface of the support pipe portion 21 is provided with a stop ring protrusion 22 that cooperates with the clamping portion 24 so that the hoisting mount is fixedly installed on the cage wall of the culture cage 1, and the right end surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com