Air disinfection equipment

An equipment and air technology, applied in the field of air treatment equipment, can solve the problems of inability to miniaturize, the anti-virus speed is not fast enough, and the one-time anti-virus rate is not high, and achieves the effect of extending the travel, preventing virus leakage, and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

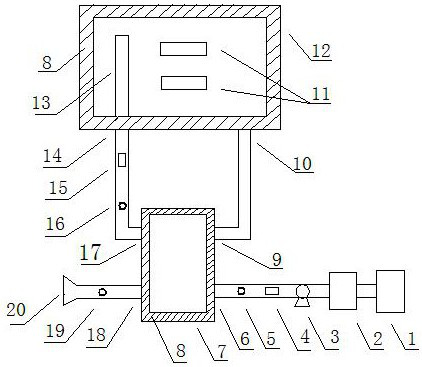

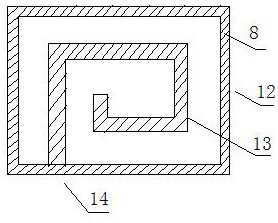

[0015] Such as figure 1 with figure 2 As shown, an air disinfection device includes a mask 1, a negative pressure chamber 2 installed behind the mask 1, and a fan 3 installed behind the negative pressure chamber 2 to form an air inlet section. The air after entering the air enters the air inlet of the plate heat exchanger 6 behind the fan 3, flows through the inner passage of the plate heat exchanger 7 to the air outlet of the plate heat exchanger 9, and absorbs heat in the plate heat exchanger 7 at the same time. The air is preheated and heated, and the virus is initially heated, dried, and dehydrated. The preheated air enters the thermostat 12 through the inlet 10 of the thermostat, exchanges heat with the surrounding objects in the thermostat 12, and is heated by the electric heating module 11 inside the thermostat. After the air is heated to the set temperature, it flows into the thermostat Copper gas pipe 13 in 12, after virus particle touches copper gas pipe 13 tube w...

Embodiment 2

[0017] Such as figure 1 As shown, the fan 3 inhales air from the mask 1 to the negative pressure chamber 2, and the negative pressure chamber 2 is a closed space of a circle, a square or other shapes. The negative pressure ensures that the air pressure in the negative pressure chamber 2 is lower than that of the mask 1. When the air pressure in the mask 1 rises, the negative pressure chamber 2 first absorbs the gas in the mask 1 to ensure that the gas does not leak out.

Embodiment 3

[0019] Such as figure 1 As shown, the flow meter-4 and the temperature sensor-5 are installed between the air outlet of the fan 3 and the air inlet-6 of the plate heat exchanger, and are used to detect the air flow and temperature of the air inlet-6 of the plate heat exchanger, and the flow rate Meter 2 15 and temperature sensor 2 16 are installed between the air outlet 14 of the thermostat and the inlet 17 of the plate heat exchanger to detect the air flow and temperature of the inlet 17 of the plate heat exchanger, and the temperature sensor 3 19 It is installed between the air outlet 18 and the air outlet 20 of the plate heat exchanger, and is used to detect the outlet air temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com