Steel plate edge rolling machine

A technology of steel plate coiling and circular knitting machines, which is applied in the field of steel plate processing, can solve the problems of inconvenient blanking of finished coiled tubes, etc., and achieve the effect of improving production efficiency, improving processing accuracy, and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

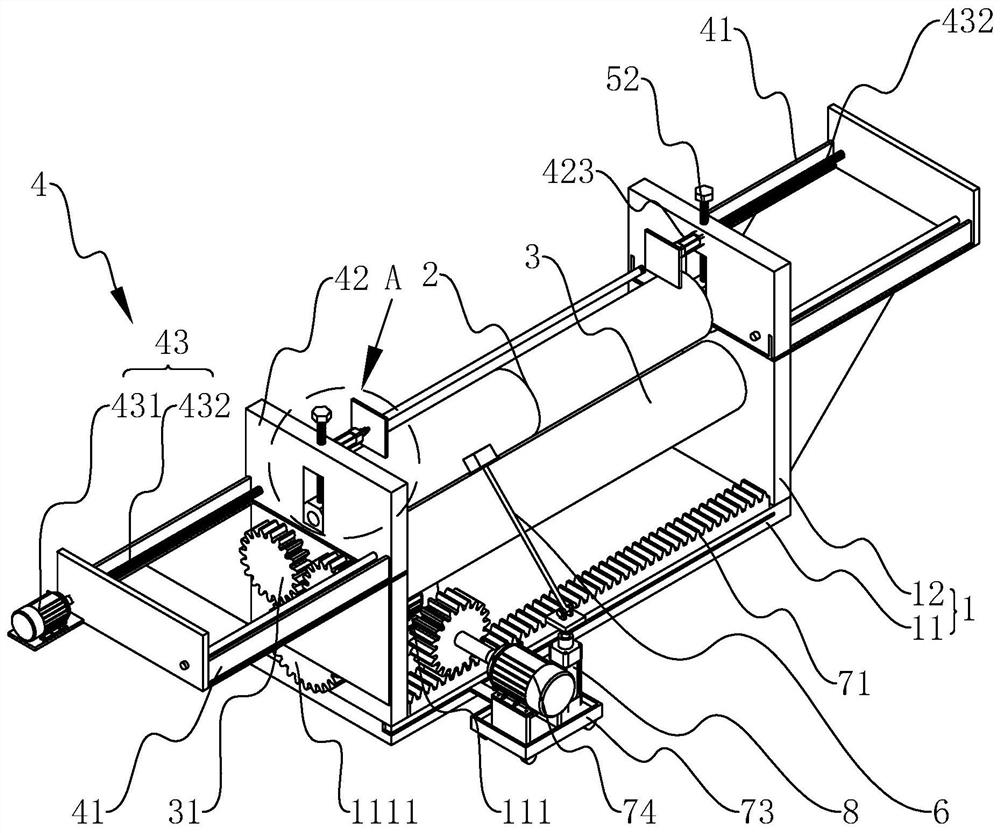

[0037] The following is attached Figure 1-5 The application is described in further detail.

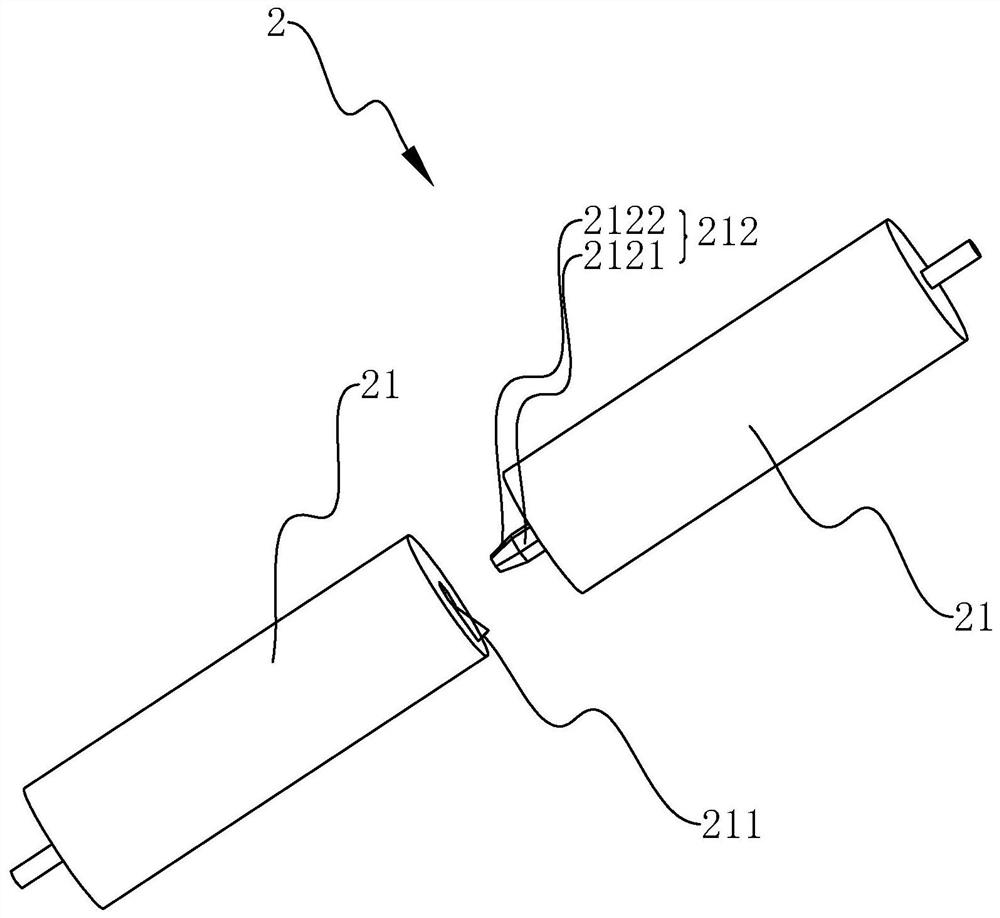

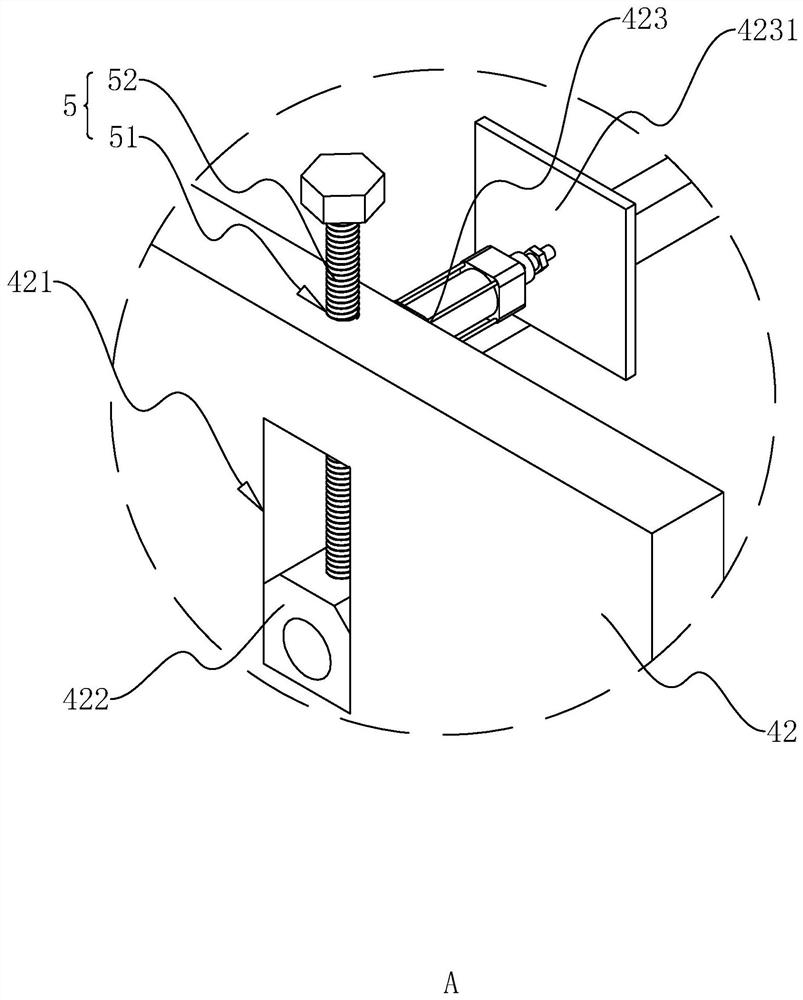

[0038] The embodiment of the present application discloses a steel plate rolling machine. refer to figure 1 , The steel plate rolling machine includes a carrier frame 1, and the carrier frame 1 includes a bottom plate 11 and side plates 12 welded to both ends of the bottom plate 11. A driven roll 2 and two driving rolls 3 are arranged between the two side plates 12. The driving roll 3 and the driven roll 2 are arranged in the horizontal direction and can rotate around their own axes. The driven roll 2 and the driving roll 3. A rolling channel for the steel plate to pass is formed between the roller surfaces. The bottom plate 11 is fixed with a rotating motor 111 by bolts, the output shaft of the rotating motor 111 is fixedly provided with a driving gear 1111, and the fixed sleeves of the two driving rollers 3 are provided with a driven gear 31, and both transmission gears are mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com