Device for preventing deviation in circular steel pipe cutting process

A steel pipe and circular technology, which is applied in the field of anti-deviation devices, can solve the problems of steel pipe cutting position deviation, fatigue, and the impact of operator work efficiency, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

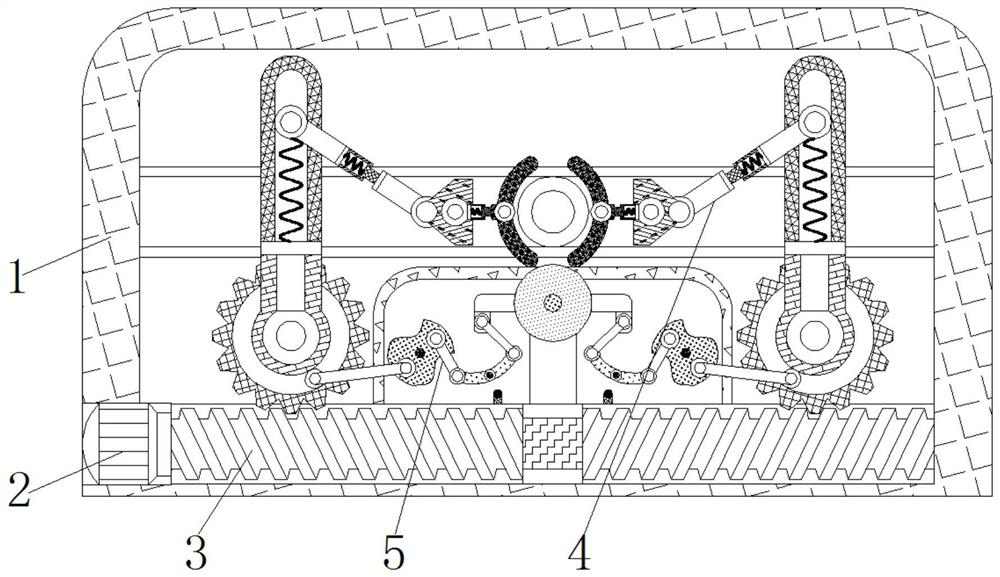

[0025] see Figure 1-3 , a device for preventing deviation during the cutting process of circular steel pipes, comprising a casing 1, a motor-2 is fixedly connected to the inside of the casing 1, a screw 3 is fixedly connected to the outside of the motor-2, and a fixing mechanism is movably connected to the outside of the screw 3 4. The fixing mechanism 4 includes a rotating wheel 41 , a rotating assembly 42 capable of being driven by the rotating wheel 41 , and a fixing assembly 43 capable of fixing the steel pipe.

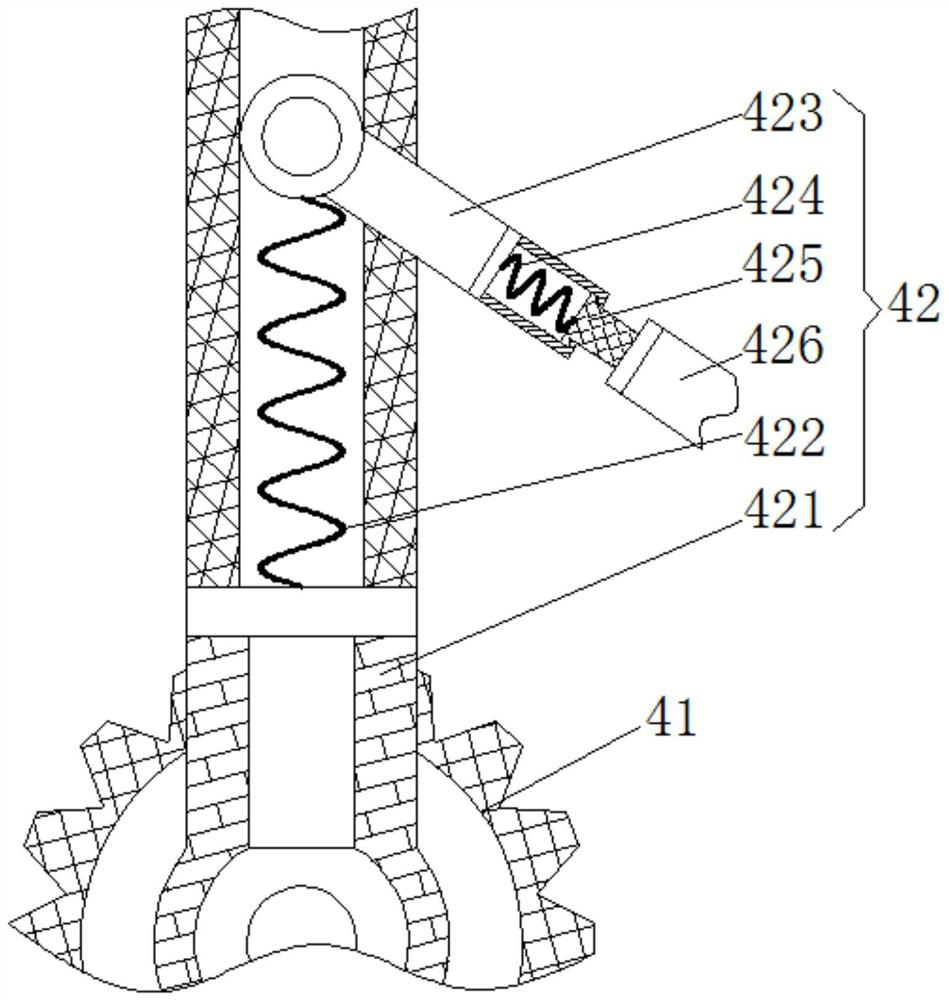

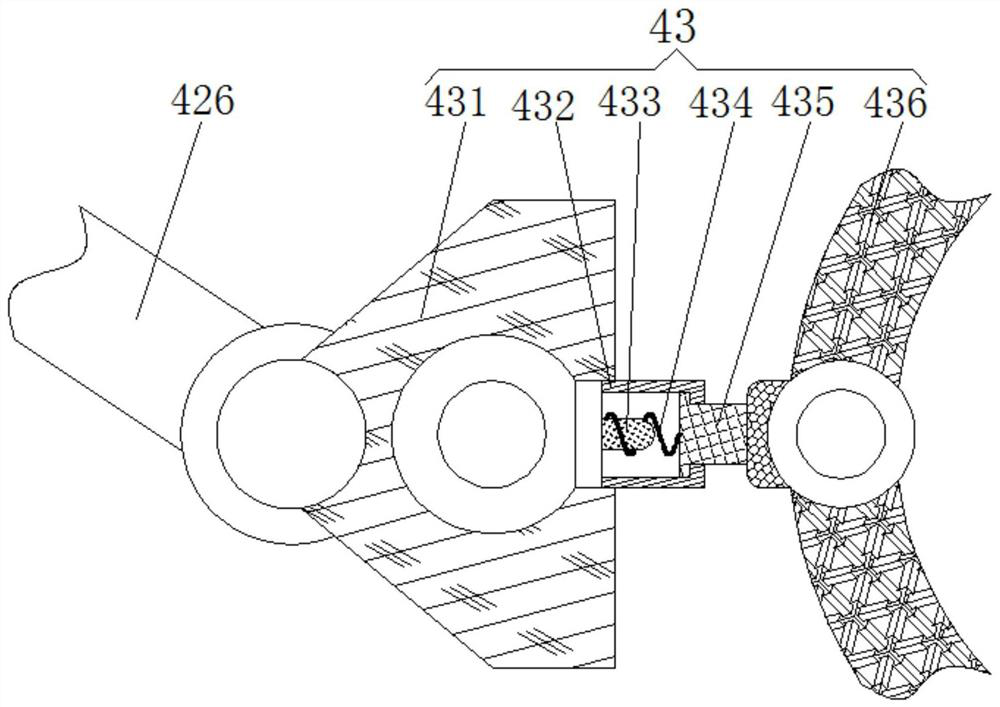

[0026] Rotation assembly 42 comprises fixed frame 421, connecting spring one 422, rotating plate one 423, connecting spring two 424, slide bar 425, rotating plate two 426, and rotating wheel 41 engagement is connected in the outside of screw rod 3, and fixed frame 421 is fixedly connected in the rotating On the outside of the wheel 41, the connecting spring one 422 is fixedly connected inside the fixed frame 421, the rotating plate one 423 is movably connected in...

Embodiment 2

[0029] see Figure 4 , the inside of the housing 1 is movably connected with a cutting mechanism 5, the cutting mechanism 5 includes a fixed groove 51, a movable assembly 52 that can be driven by the rotating wheel 41, and a lifting assembly 53 that can be lifted by the movable assembly 52, and the fixed groove 51 is fixedly connected to the casing 1 internal.

[0030] The movable assembly 52 comprises a transmission rod 521, a fixed shaft one 522, a rotating disk 523, and a connecting rod one 524. The transmission rod 521 is movably connected to the outside of the rotating wheel 41, the fixed shaft one 522 is fixedly connected to the inside of the fixed groove 51, and the rotating disk 523 The rotation is connected to the outside of the fixed shaft 1 522, the connecting rod 1 524 is movably connected to the outside of the rotating disk 523, and the end of the transmission rod 521 away from the rotating wheel 41 is movably connected to the outside of the rotating disk 523.

...

Embodiment 3

[0033] see Figure 1-4 , a device for preventing deviation during the cutting process of circular steel pipes, comprising a casing 1, a motor-2 is fixedly connected to the inside of the casing 1, a screw 3 is fixedly connected to the outside of the motor-2, and a fixing mechanism is movably connected to the outside of the screw 3 4. The fixing mechanism 4 includes a rotating wheel 41 , a rotating assembly 42 capable of being driven by the rotating wheel 41 , and a fixing assembly 43 capable of fixing the steel pipe.

[0034] Rotation assembly 42 comprises fixed frame 421, connecting spring one 422, rotating plate one 423, connecting spring two 424, slide bar 425, rotating plate two 426, and rotating wheel 41 engagement is connected in the outside of screw rod 3, and fixed frame 421 is fixedly connected in the rotating On the outside of the wheel 41, the connecting spring one 422 is fixedly connected inside the fixed frame 421, the rotating plate one 423 is movably connected in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com