Material suction channel of split type vacuum material suction machine

A vacuum suction machine, split-type technology, applied in the field of suction machines, can solve the problems of inconvenient assembly of the suction pipe and external pipes, cumbersome and time-consuming disassembly operations, and falling off of external pipes, so as to achieve convenient disassembly and assembly and avoid safety accidents , Increase the effect of frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

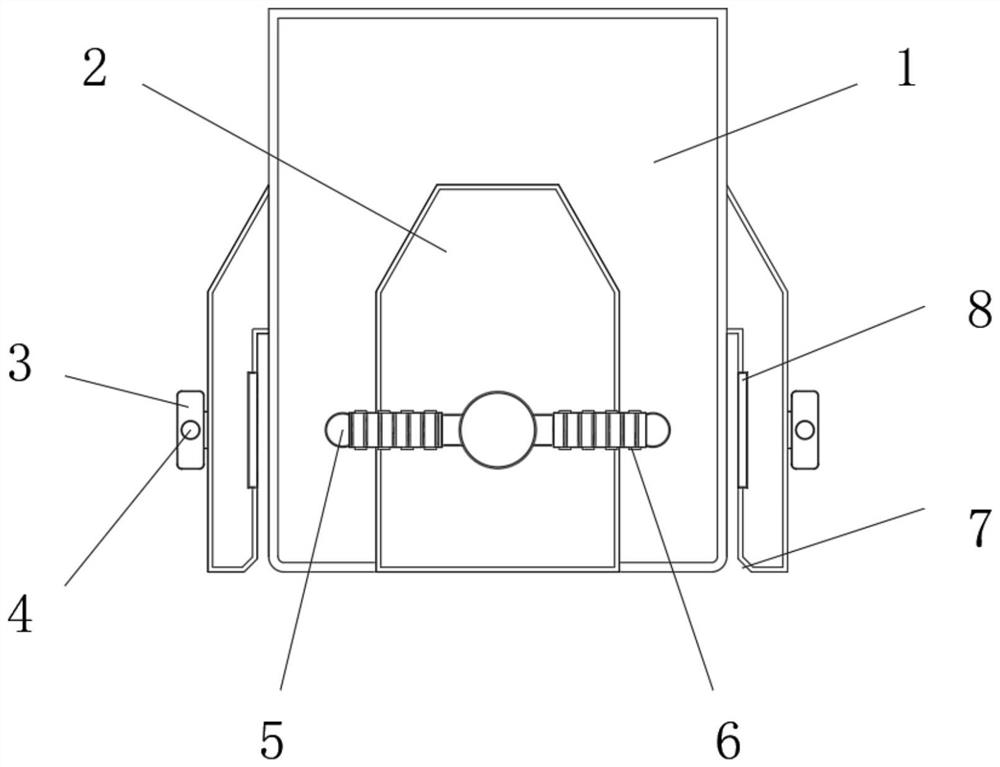

[0029] Please refer to figure 1 , Figure 4 with Figure 5 As shown, the present invention provides a suction channel of a split-type vacuum suction machine, including a suction pipe 1, the outer wall of the suction pipe 1 is radially connected with a fixed seat 2, and the inner wall of the front end of the fixed seat 2 is connected to the suction pipe. The side outer wall of the pipe 1 forms a clamping groove, and the fixing seat 2 is provided with a pressing part 15 on the surface of the clamping groove, and the pressing part 15 is threadedly connected with the fixing seat 2. The plate 20 and the base plate 16 are elastically connected. The suction pipe 1 of the split vacuum suction machine must be used in combination with an external pipe. 2 along the radial direction of the suction pipe 1 is conducive to the fixation and stability of the external pipe. The pressing part 15 inside the clamping groove resists and compresses the external pipe to ensure that the assembly of ...

Embodiment 2

[0034] This embodiment is an improvement made on Embodiment 1. For details, please refer to figure 1 with Figure 4 , the midpoint of the inner end of the pressing member 15 is connected with a screw 14, the outer wall of the fixing seat 2 is provided with a threaded hole 13 relative to the screw 14, and the end of the screw 14 runs through the threaded hole 13 and is connected with a knob 3. The outer wall of the rod 14 and the inner wall of the threaded hole 13 are screwed together, the pressing part 15 is assembled with the screw rod 14, the screw rod 14 rotates in or out relative to the screw hole 13, and the screw rod 14 pushes and compresses The space between the parts 15 is adjusted relative to the clamping groove, the pressing part 15 is suitable for external pipes of various specifications and wall thicknesses, and the knob 3 is conducive to the rotation control of the screw mandrel 14.

[0035] Such as figure 1 As shown, the present invention discloses that the sid...

Embodiment 3

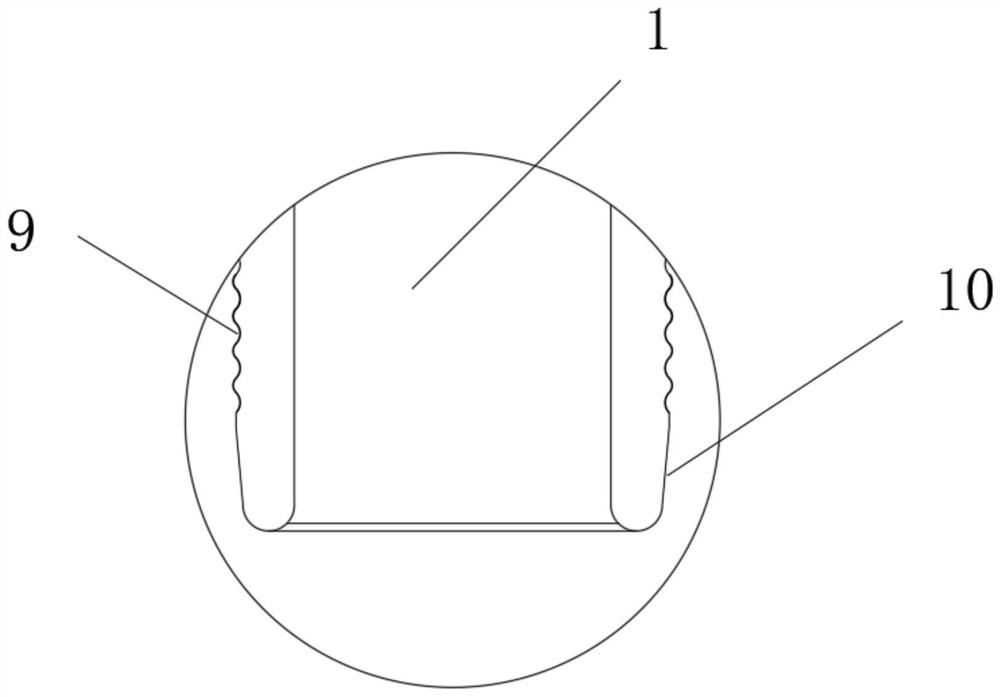

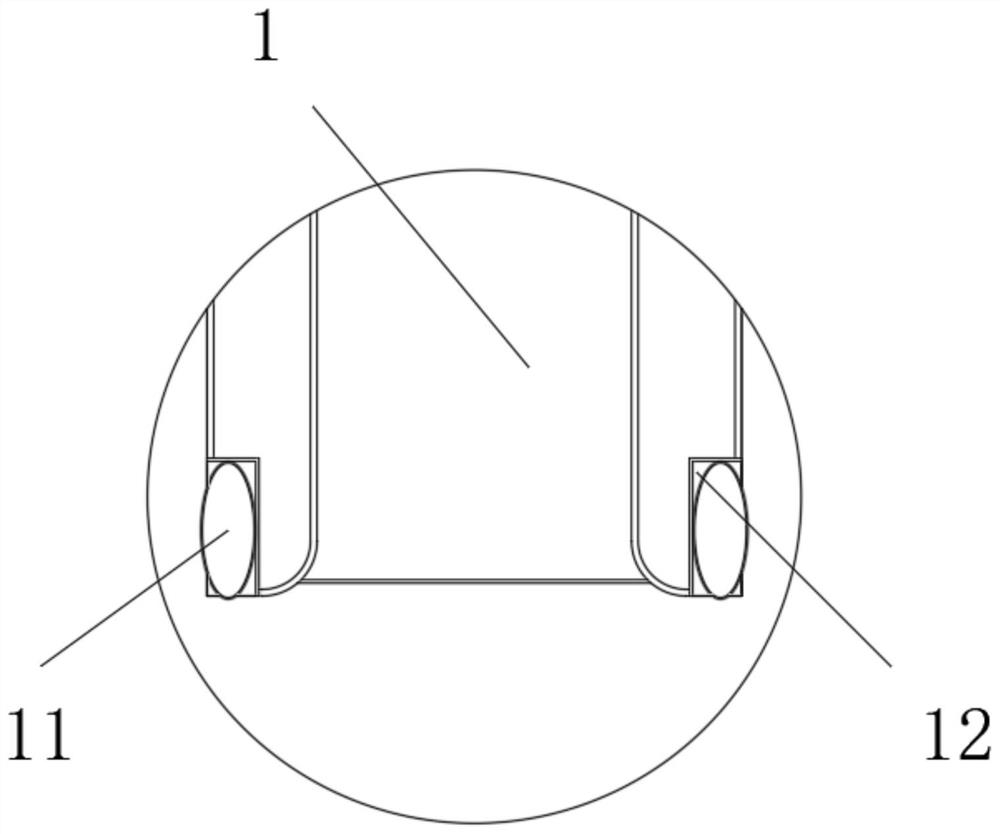

[0037] This embodiment is an improvement made on Embodiment 1. For details, please refer to Figure 4 with Figure 5 , the base plate 16 is fixed on the end of the screw rod 14, and the backing plate 20 covers and is arranged on the outer end surface of the base plate 16, and a large spring 17 is laid symmetrically between the interlayer of the base plate 16 and the backing plate 20, and the backing plate 20 of the pressing member 15 and the The large spring 17 between the base plate 16 of the pressing part 15 can be deformed and there is a certain buffer, which is conducive to the matching of the external pipe and the pressing part 15. At the same time, the large spring 17 ensures that the pressing part 15 exerts a continuous and stable force on the external pipe , The uniform and symmetrical laying of the large spring 17 ensures that the pressing member 15 exerts a continuous and stable force on the external pipe.

[0038] Such as Figure 4 As shown, the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com