Shutter blade for ship

A shutter and blade technology, applied in the field of marine shutter blades, can solve the problems of being unable to block nuclear, biochemical and other pollutants, affecting the tightness of the shutters, and not having airtightness, etc., achieving the effect of novel airtight form, light weight, and improved tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

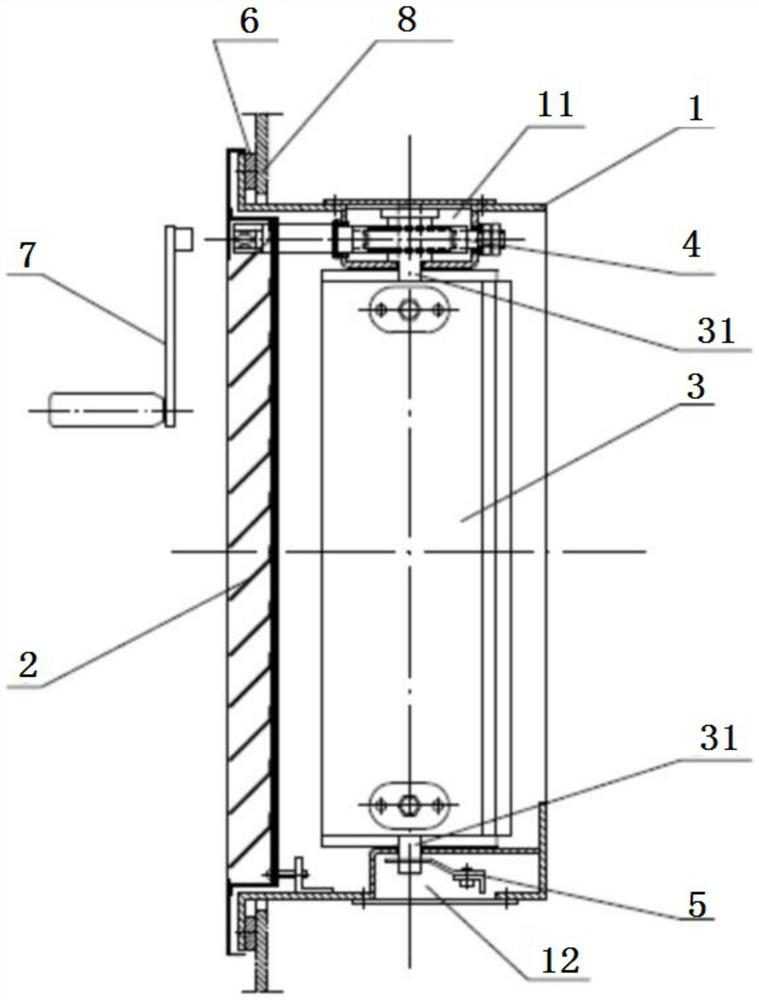

[0053] Embodiment 1, the shape of the first folded plate 35 of the marine shutter blade in this embodiment is the same as the shape of the second folded plate 36, as Figure 11-13 As shown, both ends of the cavity formed by the first folded plate 35 and the second folded plate 36 are combined and sealed by the third folded plate 37 and the first sealing strip 38 .

[0054] Both the first folded plate 35 and the second folded plate 36 are composed of a first U-shaped plate body 313 with a flanging 312 and a first protective folded edge 314 arranged at one end of the first U-shaped plate body 313. A U-shaped plate body 313 is provided with a first mounting shaft hole 315 in the middle. The first protective flap 314 is bent or bent toward the opening direction of the first U-shaped plate body 313 to shield and protect the first sealing strip 38 when the shutter is closed. The first protective flap 314 is made of a stainless steel sheet (1mm) is formed by digital punching and num...

Embodiment 2

[0059] Embodiment 2, in this embodiment, the shape of the first folded plate 35 of the marine louver blade is different from the shape of the second folded plate 36, as Figure 7-10 As shown, the first end of the cavity formed by the combination of the first flap 35 and the second flap 36 is only sealed by the first sealing strip 38, and the second end is sealed by the combination of the third flap 37 and the first sealing strip 38. . The first flap 35 is made up of a second U-shaped plate body 318 with a flange 312, a second protective flange 319 arranged at one end of the second U-shaped plate body 318, and the second protective flange 319 faces the second The opening direction of the U-shaped plate body 318 is bent or bent to shield and protect the first sealing strip 38 when the shutter is closed, and the second protective fold 314 is made of a stainless steel sheet (1mm) through several punching processes and numerically controlled folds. As a result, preferably, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com