Method for repairing screw hole of normal-pressure cutterhead and cutterhead cylinder of slurry balance shield tunneling machine

A mud-water balance and repair method technology, which is applied in earthwork drilling, mining equipment, tunnels, etc., can solve the problems of re-maintenance of damaged wire sleeves, damaged inner wires in the bolt hole of the knife barrel, and large diameter of bolt hole expansion, etc., to achieve The effect of avoiding damage to repair again, reducing construction risk, saving time cost and capital cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

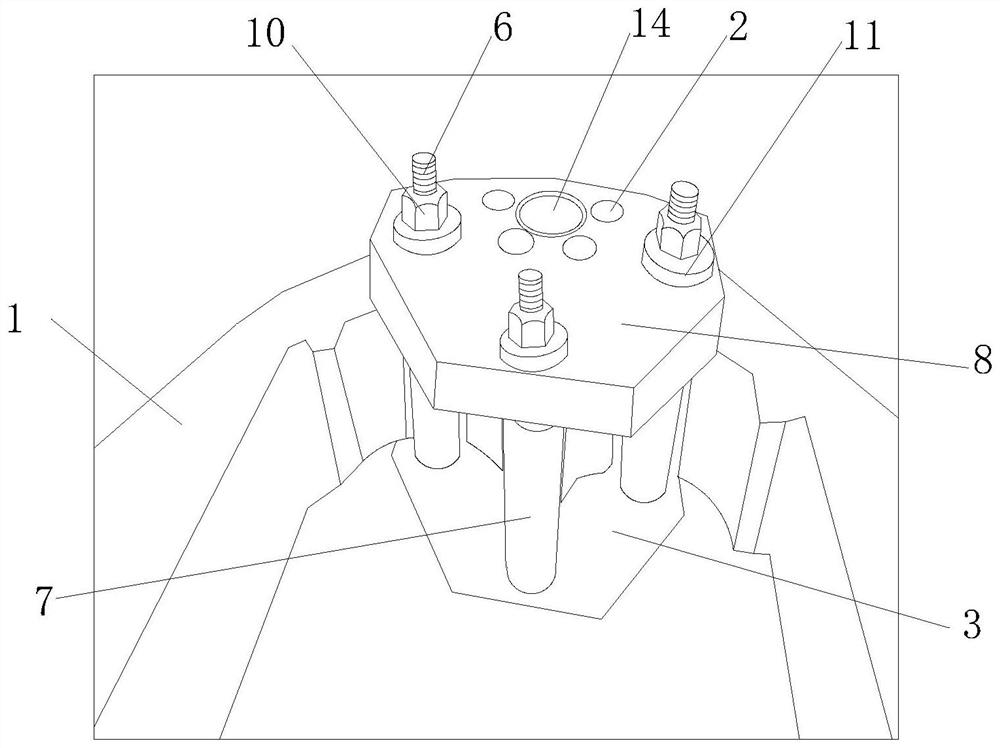

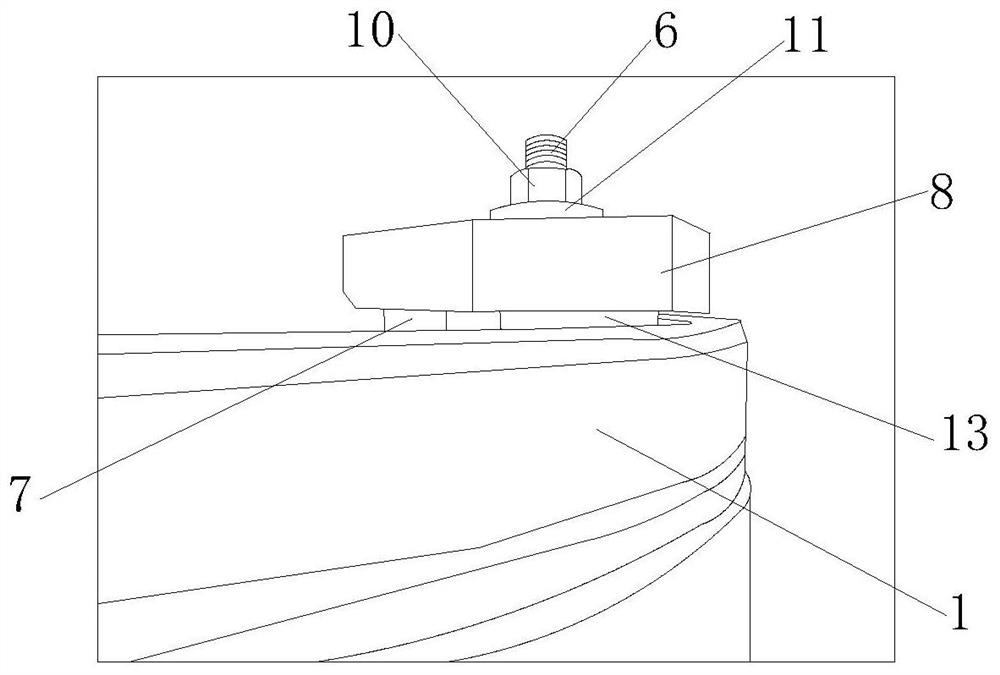

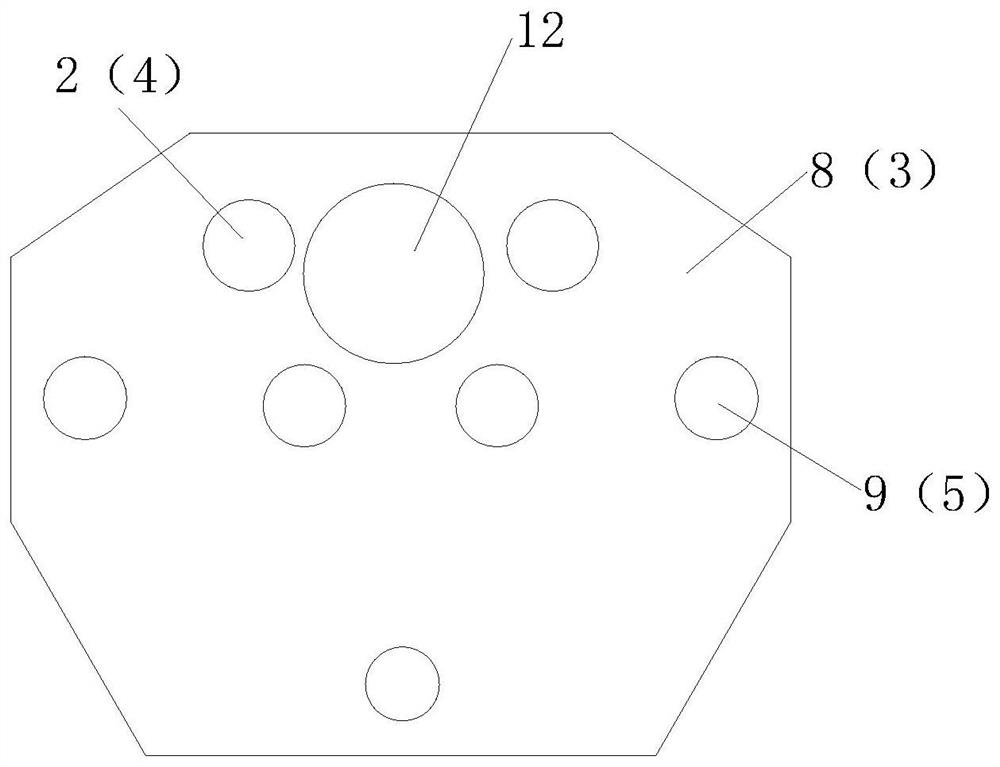

[0040] Such as Figure 1 to Figure 4 The shown method for repairing the screw holes of the normal pressure cutter head and barrel of a mud-water balance shield machine includes the following steps:

[0041] Step 1. Clean and fix the knife barrel to be repaired: clean the outer surface of the knife barrel to be repaired and the screw holes on the knife barrel to be repaired; make the flange of the knife barrel to be repaired face down and place it on the drill press, adjust The flatness of the cutter barrel to be repaired is to ensure that the flatness of the cutter barrel to be repaired is not greater than 0.5mm, and the cutter barrel to be repaired is reversely fixed on the drilling machine by a fixing member;

[0042]Step 2. Install the positioning tooling, the process is as follows:

[0043] Step 201, confirm the number and position of the screw holes to be repaired on the fixed end 1 of the knife holder, install the lower positioning plate 3 horizontally at the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com