Wear-resistant air compressor pistons used in new energy vehicles

A technology for new energy vehicles and air compressors, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of improving piston wear resistance, reducing friction strength, and unable to greatly improve piston life, etc. Achieve the effect of reducing wear strength, reducing friction strength and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

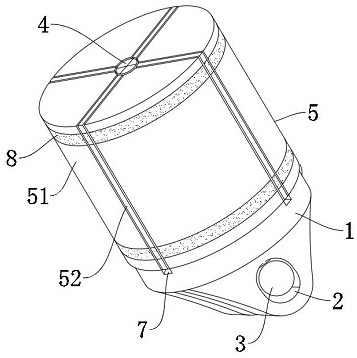

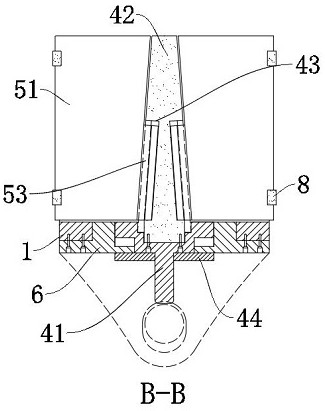

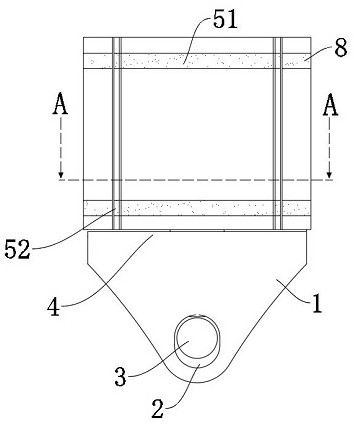

[0020] see Figure 1-8 , an embodiment 1 provided by the present invention: including a base 1, a waist hole 2 and a shaft pin 3, the base 1 is composed of a disk and two connecting piles, and the two connecting piles are welded on both sides of the bottom end of the disk , a waist hole 2 is opened on the connecting pile, and a shaft pin 3 is arranged in the waist hole 2, such as figure 1 As shown, the pivot pin 3 is used to connect external parts.

[0021] The bottom of the base 1 is fixed with a limit seat 6, and the center of the limit seat 6 protrudes and is provided with a through hole. The top of the limit seat 6 runs through the disc and is flush with the upper surface of the disc. It is connected and fixed by bolts to the disc. The upper surface of the base 1 is provided with an engaging assembly 4. The engaging assembly 4 includes a fixing seat 41 and an engaging platform 42. The bottom of the fixing seat 41 is stepped, and the bottom end of the fixing seat 41 runs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com