Self-parallel rolling linear guide rail

A linear guide, guide rail technology, applied in the direction of linear motion bearings, bearings, shafts and bearings, can solve problems such as poor installation accuracy guide rail pair life, waste of resources, guide rail pair damage, etc., and achieve the effect of solving poor installation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

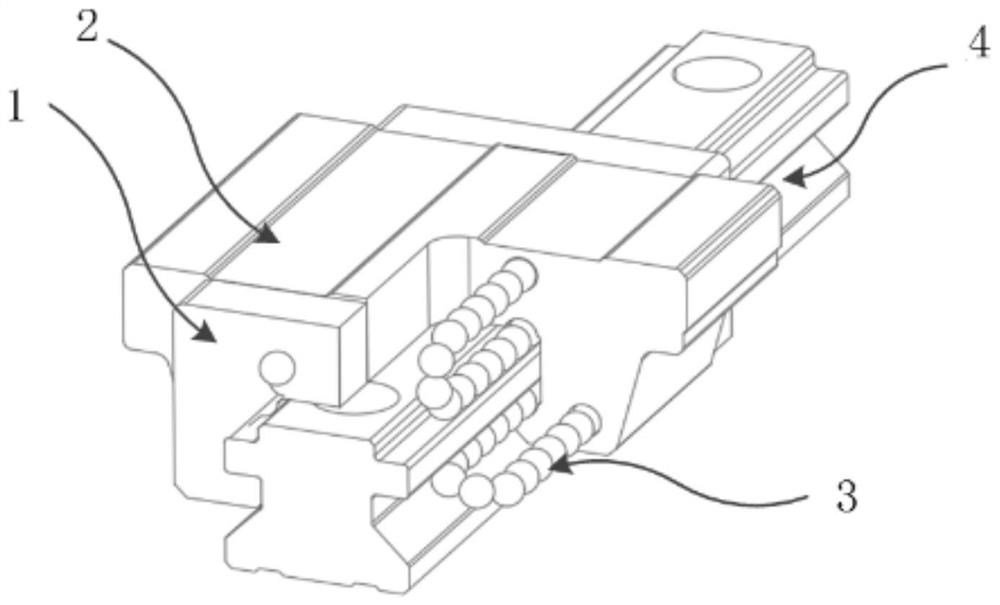

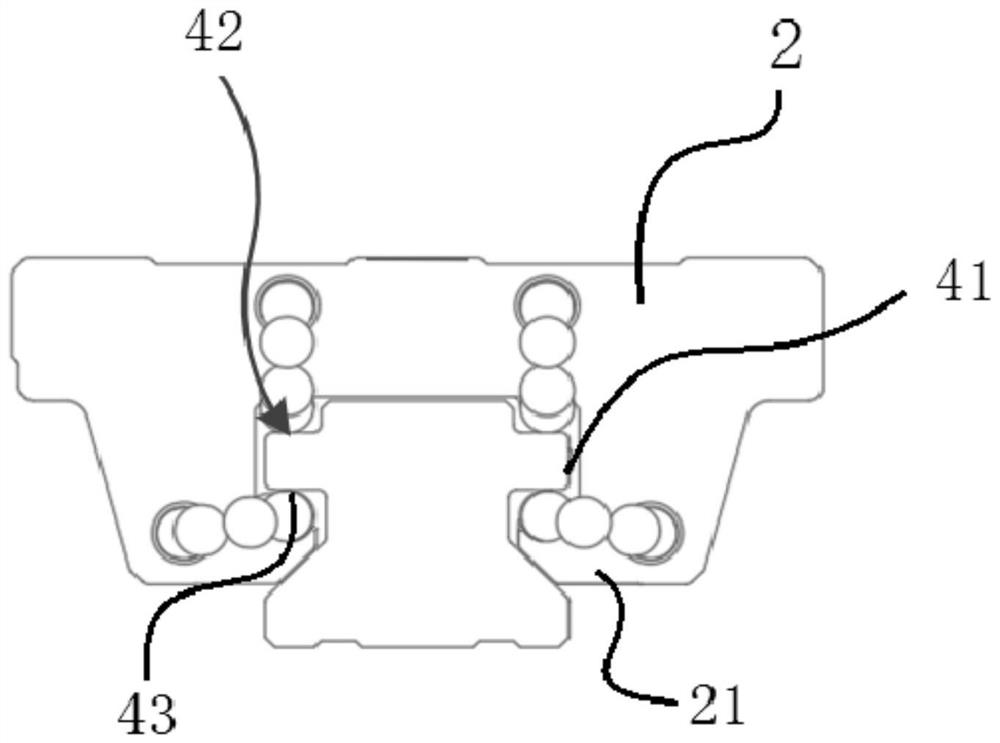

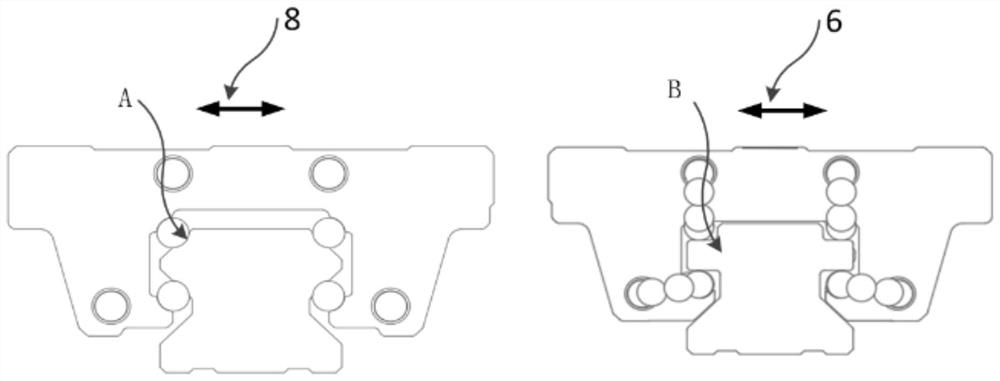

[0018] like figure 1 and figure 2 , a self-parallel rolling linear guide rail of the present invention, including a reverser 1, a slider 2, a guide rail 4 and a rolling line 3 composed of several steel balls, the slider 2 is slidably connected to the guide rail 4, and two reversers 1 is fixed on the front and rear sides of the slider 2, and the rolling line 3 rolls between the slider 2 and the guide rail 4, and realizes circular reciprocating motion through the reverser 1.

[0019] Two rectangular bosses 41 are symmetrically arranged on the left and right side walls of the guide rail 4, and the first right angle surface 42 is formed between the upper end surface of the rectangular boss 41 and the side wall of the guide rail 4, and the lower end surface of the rectangular boss 41 and the guide rail 4 The second right-angled surface 43 is formed between the side walls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com