A calcium carbide unloading system

A technology of calcium carbide and drive motor, which is applied in the direction of furnace, electric charge control, furnace components, etc. It can solve the problems of inability to achieve precise positioning, uneven force on the trolley out of the furnace, and the trolley falling out of the furnace, so as to improve the uneven force and instability Problems and difficult to control, solve the difficulty of baking, avoid the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

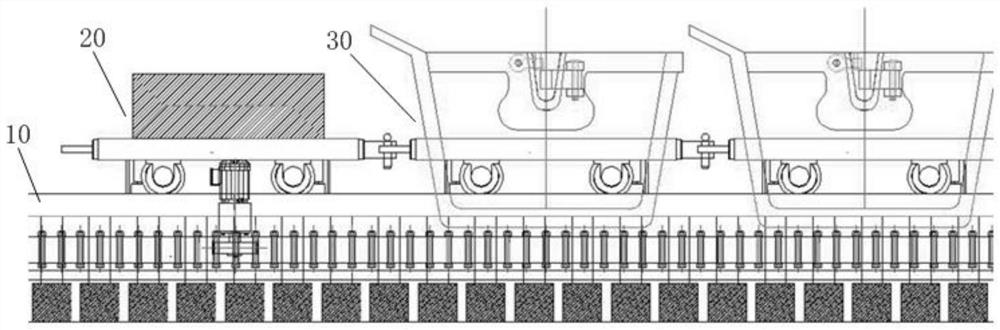

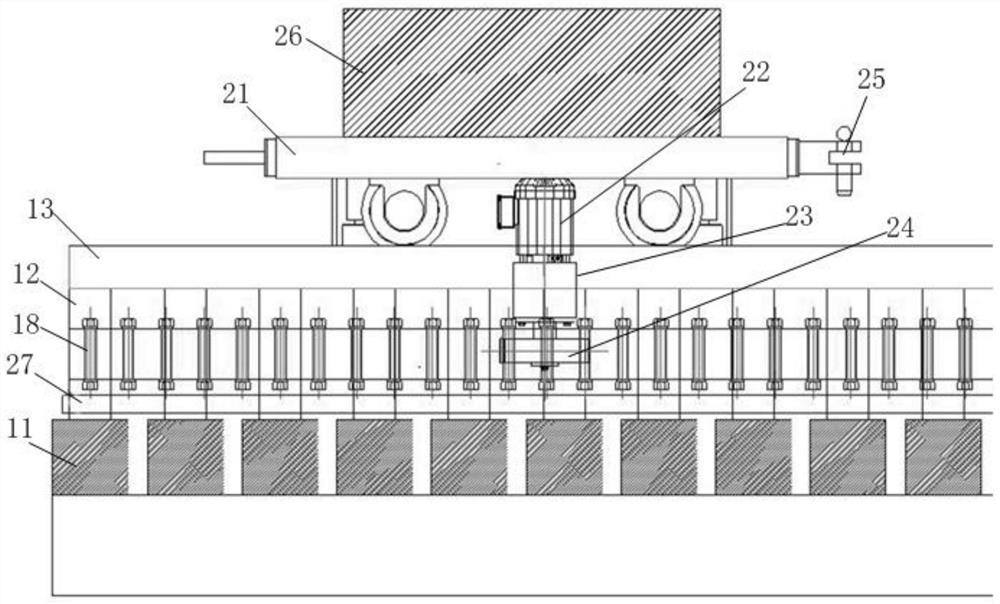

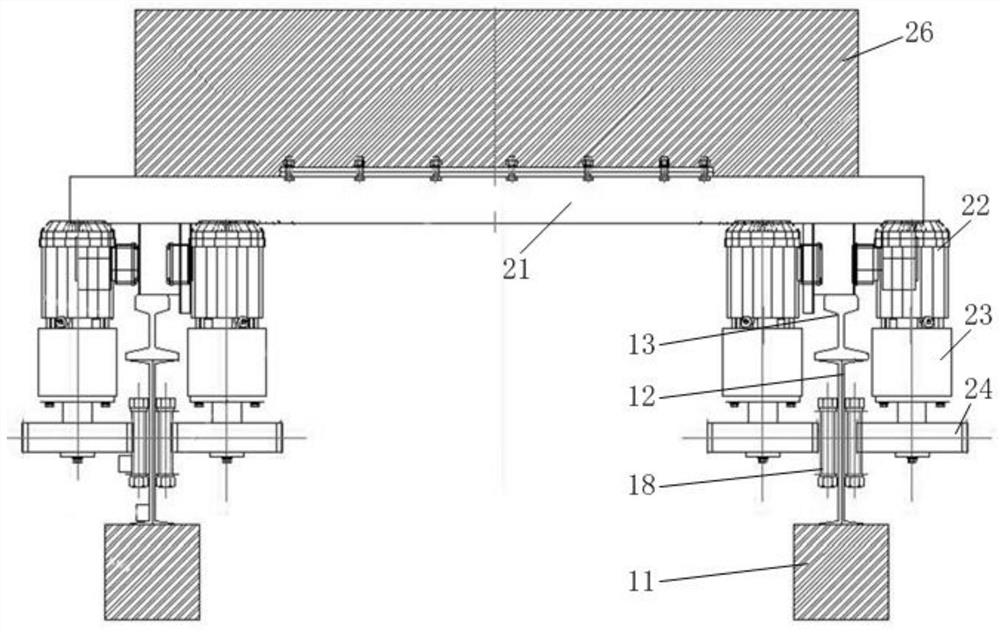

[0039] like Figure 1 to Figure 8 As shown, the calcium carbide tapping system includes a high-mounted rail system 10 laid on the tapping path, and a tapping vehicle arranged on the high-level rail system, the tapping truck includes a self-propelled tractor 20, and at least one in The furnace trolleys 30 are sequentially connected after the self-propelled tractor, wherein the number of the furnace trolleys can be specifically configured according to the amount of high temperature calcium carbide released.

[0040]The high-mounted track system 10 includes a castable ladle column 11 fixedly arranged on the ground of the furnace path, a number of profiled steel pillars 12 fixedly arranged on the castabled ladle column along the blasting direction, and fixedly arranged on the profiled steel column and kept with the ground. A rail body 13 with a certain height, and a guide mechanism arranged on the side of the profiled steel pillar and arranged in the direction of the furnace, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com