Automatic inspection method, system and device based on flight at specified height

An automatic inspection and altitude technology, applied in the control/adjustment system, vehicle position/route/altitude control, non-electric variable control, etc., can solve the problem of low inspection efficiency, inconsistent inspection photo data standards, long cycle, etc. problems, to achieve the effect of normative and accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

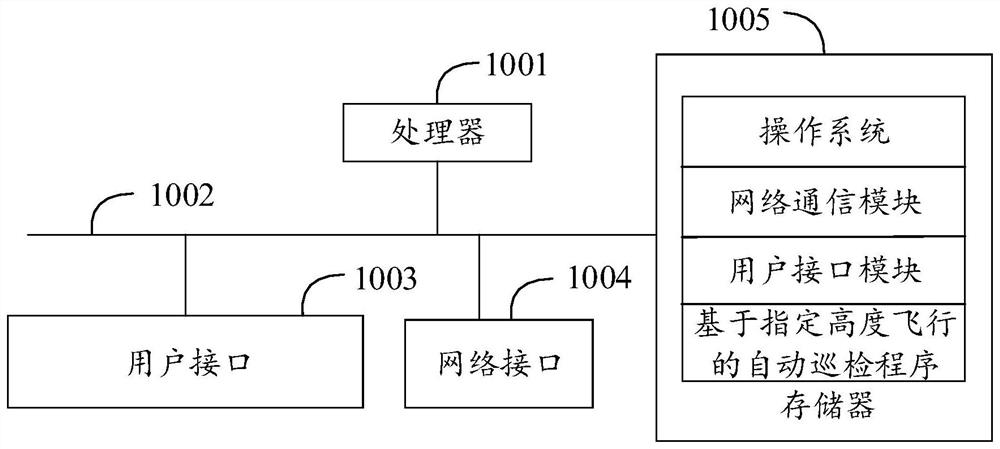

[0047] like figure 1 as shown, figure 1 It is a schematic diagram of the terminal structure of the hardware operating environment involved in the solution of the embodiment of the present invention.

[0048] The embodiment terminal of the present invention can be PC, also can be smart mobile phone, panel computer, e-book reader, MP3 (Moving Picture Experts Group Audio Layer III, moving picture expert compresses standard audio level 3) player, MP4 (Moving Picture Experts Group Audio Layer III) player, MP4 (Moving Picture Experts Group Audio Layer IV, dynamic image expert compression standard audio layer 3) Players, portable computers and other mobile terminal devices with display functions.

[0049] likefigure 1 As shown, the terminal may include: a processor 1001 , such as a CPU, a network interface 1004 , a user in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com