Automatic testing device for power supply connecting plate

A technology of automatic testing and power supply, which is applied in the direction of measuring devices, measuring device shells, and parts of electrical measuring instruments. Effects of shifting positions and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

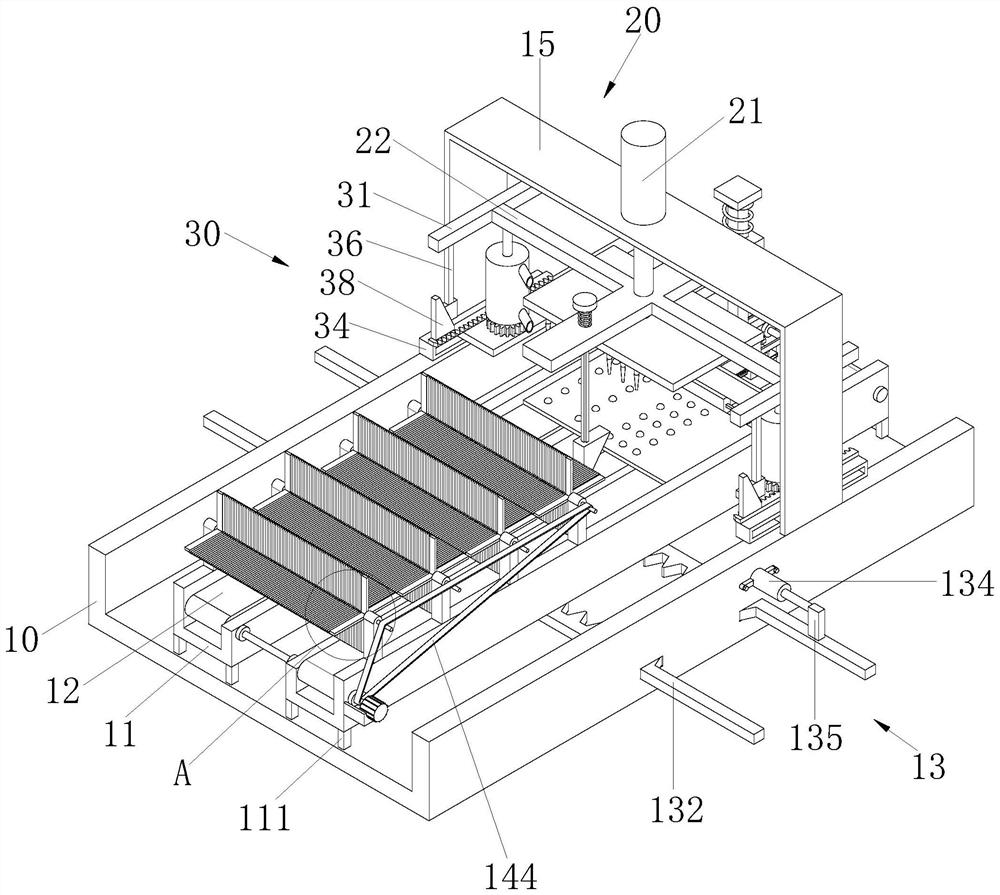

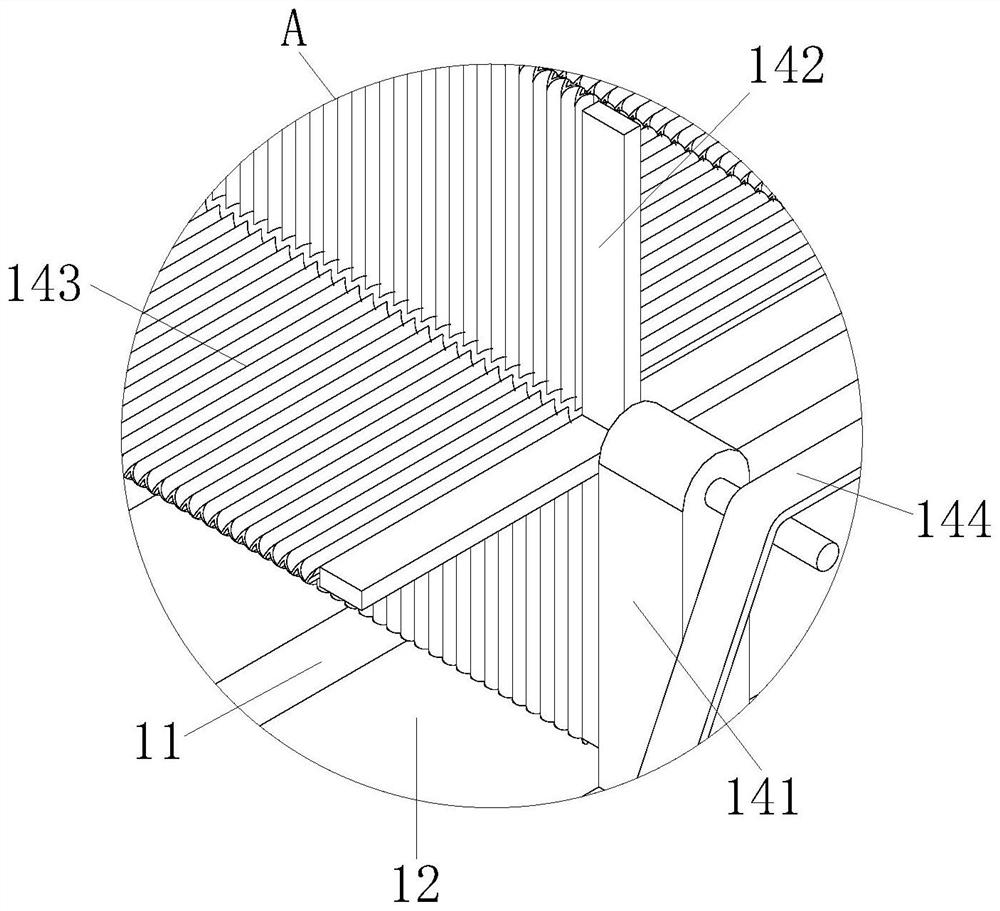

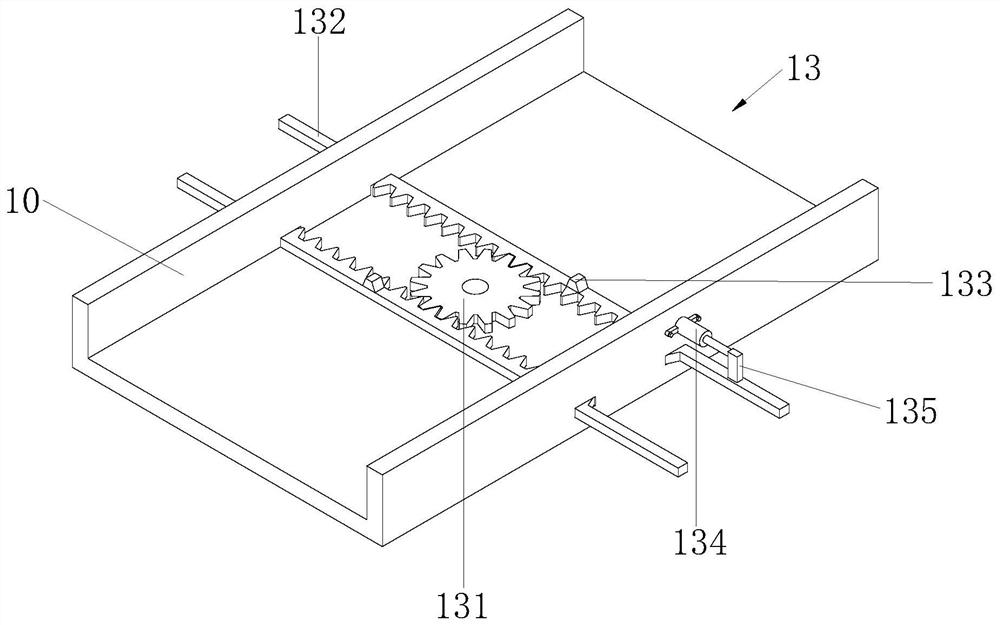

[0030] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5, an automatic test device for a power supply connection board, comprising a base 10 and a 匚-shaped plate 11 symmetrically arranged at the bottom end of the inner wall of the base 10, the height of the opposite sides of the two 匚-shaped plates 11 is greater than the height of the opposite side, and the bottom of the 匚-shaped plate 11 There are a plurality of 111, and balls are embedded in the rotation of the bottom end of 111, which reduces the friction force between the two 匚-shaped plates 11 and the base 10, and also plays a certain supporting role for the two 匚-shaped plates 11. The grooves of the template 11 are symmetrically connected with transmission shafts, the outer walls of the two transmission shafts are provided with a conveyor belt 12, and both ends of the two transmission shafts slide through the side walls of the template 11 and are fixedly connected to a Circular baffles, telescopic ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com