Rotary self-sharpening cutter mechanism

A technology of a rotary drive mechanism and a rotary transmission mechanism, which is applied to the parts of grinding machine tools, grinding drive devices, grinding/polishing equipment, etc., which can solve the problems of potential safety hazards, increased load, and increased processing costs, etc., to achieve Reduce defective product rate and failure rate, improve service life, and increase the effect of cutting times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

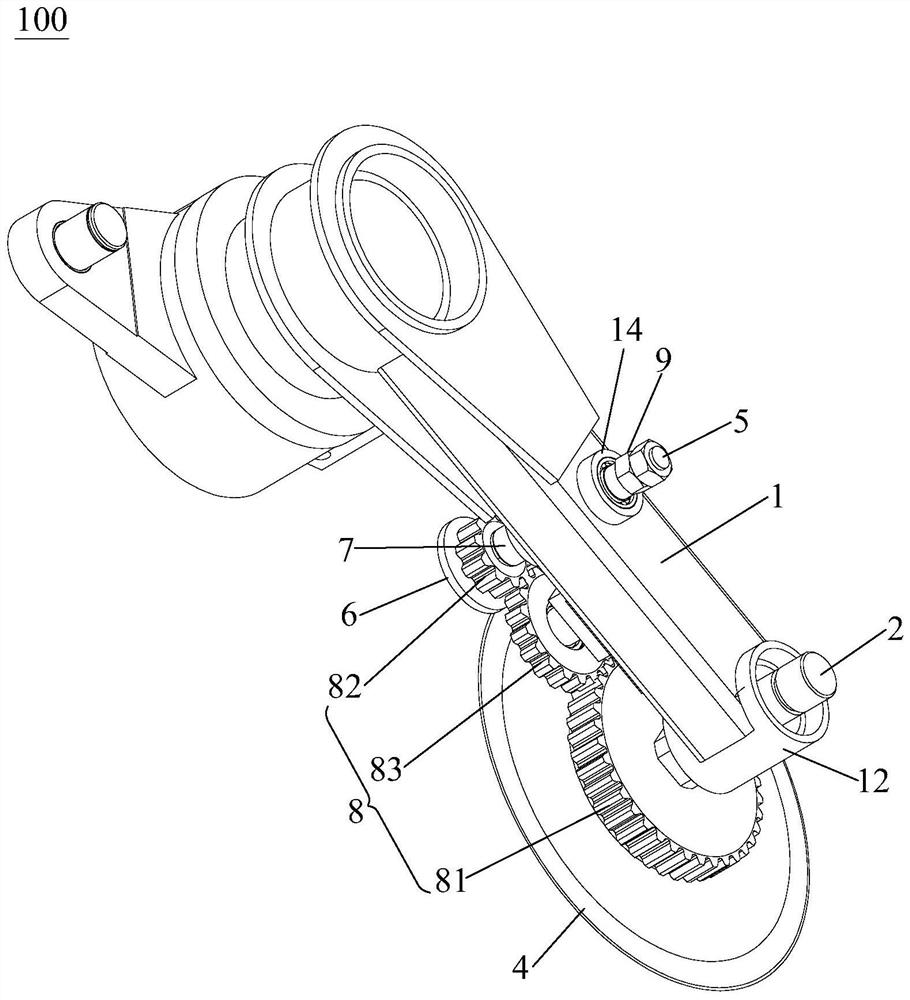

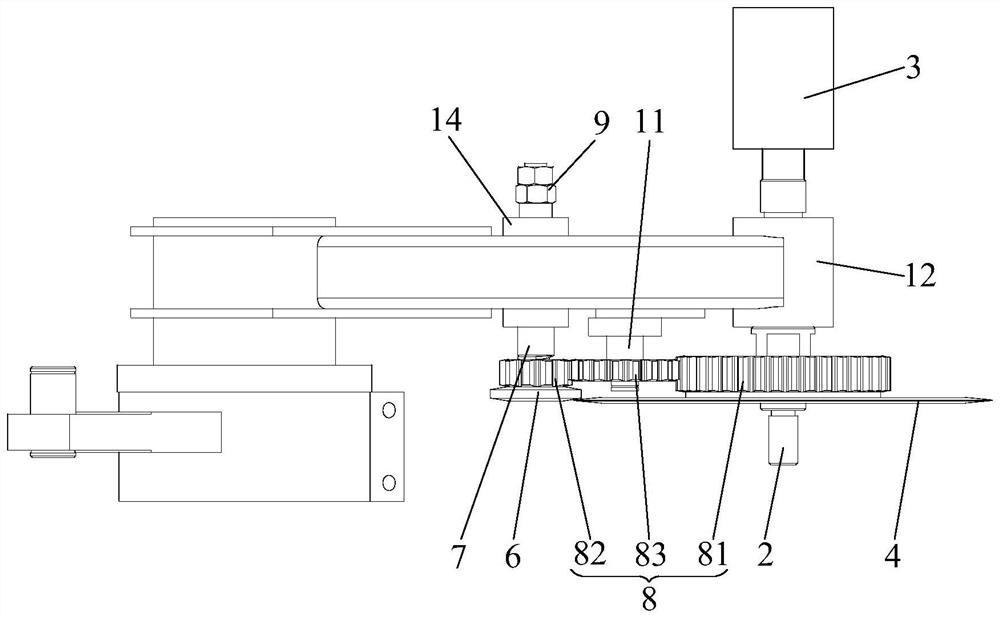

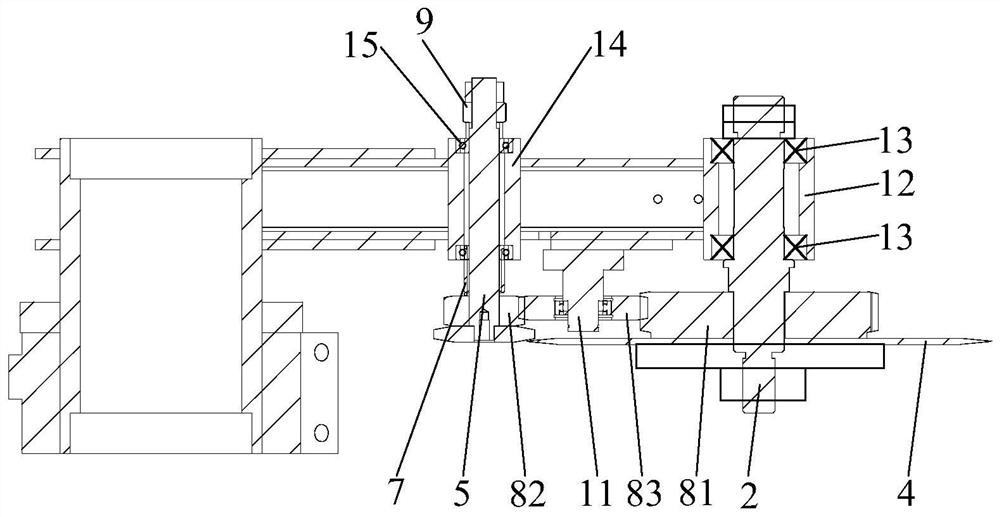

[0020] see Figure 1 to Figure 3 The rotary self-sharpening knife mechanism 100 of the present invention includes a knife arm 1, a first rotating shaft 2, a rotating drive mechanism 3, a cutting knife 4, a second rotating shaft 5, a knife sharpening member 6, an elastic member 7 and a rotating transmission mechanism 8, The first rotating shaft 2 is rotatably installed on the knife arm 1, the output end of the rotating drive mechanism 3 is connected to the first rotating shaft 2, the cutting knife 4 is fixedly connected to the first rotating shaft 2, and the second rotating shaft 5 is movably arranged on the On the knife arm 1, the knife sharpening piece 6 is fixedly connected to one end of the second rotating shaft 5, and the elastic piece 7 is arranged between t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap