Glass tempering treatment equipment and dedicated liquid washing mechanism thereof

A technology for processing equipment and special fluids, used in metal processing equipment, grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

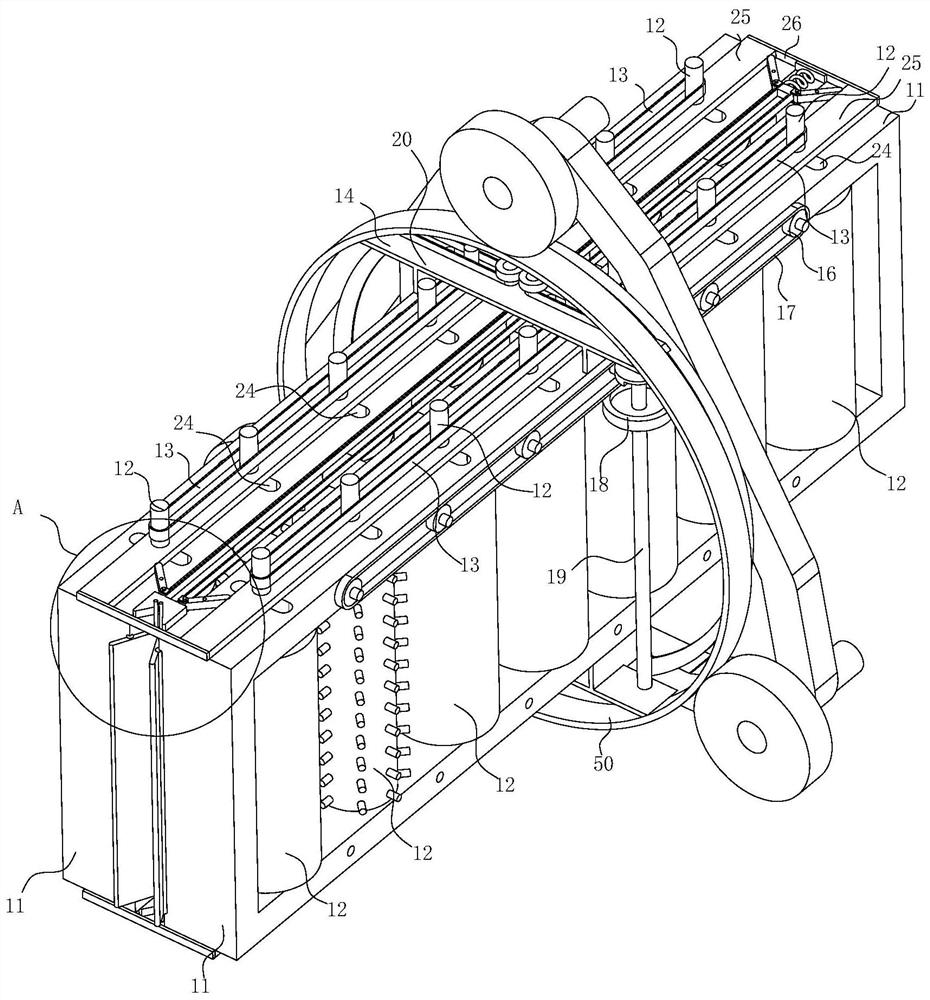

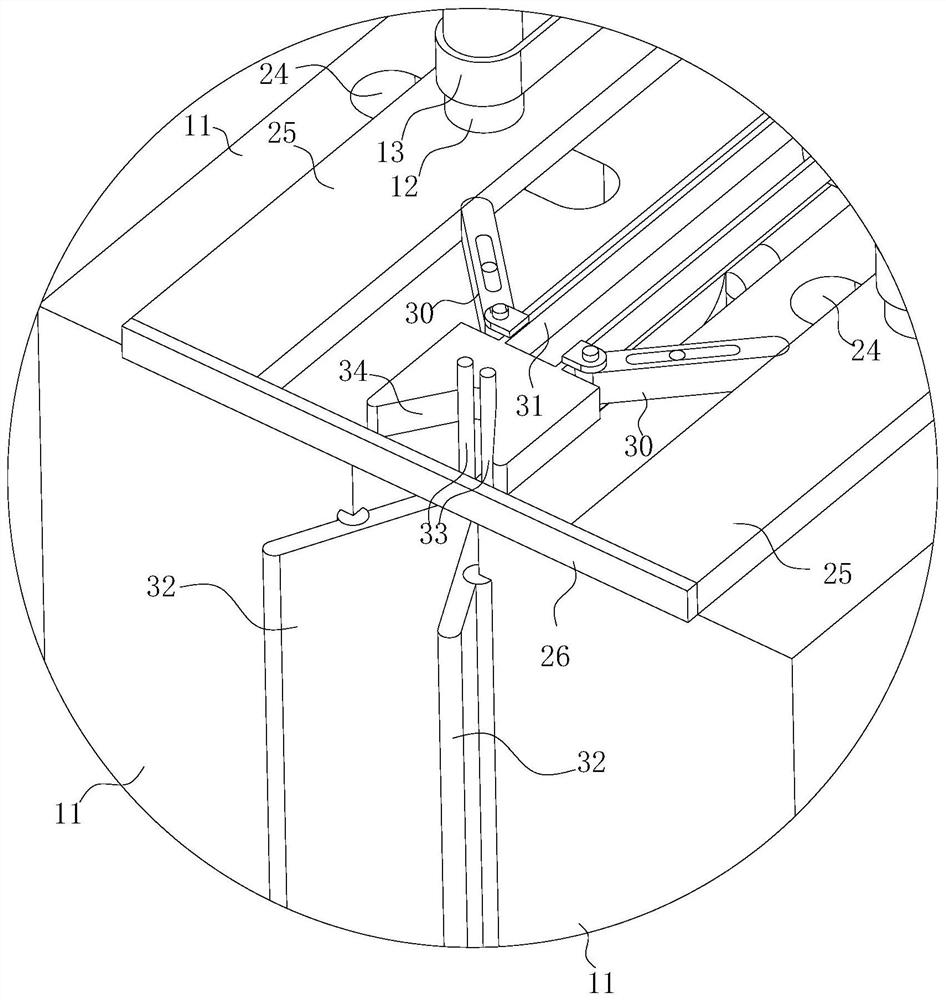

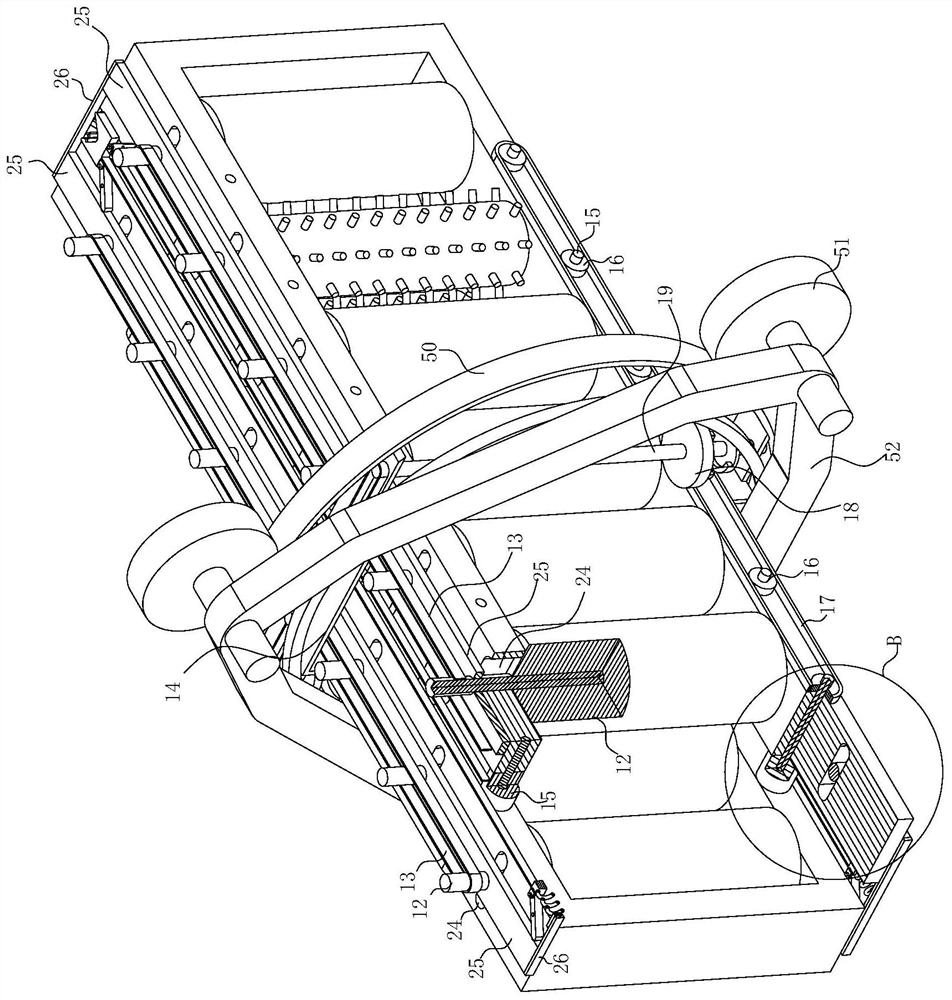

[0081] see Figure 1-9, the present invention provides a technical solution: a glass tempering treatment equipment, including a motor 10 and two sets of symmetrical fixed rectangular frames 11, the motor 10 is fixedly installed in the center of the lower ends of the two sets of rectangular frames 11 through brackets, and the two rectangular frames 11 A plurality of polishing rollers 12 are vertically arranged at equal intervals on the inner wall, and the driving shafts of the polishing rollers 12 on the same side pass through the upper end of the side wall of the rectangular frame 11 and are respectively sleeved with a polishing timing belt 13 on the outer wall. In order to change the power switching mechanism 14 for changing the rotation direction of the left and right side polishing sticks 12, a plurality of equal-spaced grinding wheels 15 for grinding the sides of the glass are rotated between the side walls where the lower ends of the two rectangular frames 11 are close to ...

Embodiment 2

[0101] see Figure 10-15 , a special liquid washing mechanism, comprising: a housing 61, a cover plate 62, a control unit fixedly mounted on the bottom of the cover plate 62, a rotating unit for movably adapting the control unit, the control unit Including a liquid storage shell 71 and an infusion sleeve 72, the bottom of the housing 61 is provided with a liquid outlet, the top of the housing 61 is fixedly connected with the cover plate 62, and the top of the cover plate 62 is provided with an inlet The liquid port, the bottom of the cover plate 62 is fixedly connected with the liquid storage shell 71, the bottom of the liquid storage shell 71 is evenly opened with a delivery port, and the bottom of the liquid storage shell 71 is fixedly connected with the infusion sleeve 72 , the rotating unit is movably disposed inside the casing 61 . Further, the liquid inlet port communicates with the liquid storage shell 71 , and the infusion port is provided corresponding to the infusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com