New energy automobile reinforced threshold

A new energy vehicle and threshold technology, which is applied to vehicle components, superstructure sub-assemblies, power units, etc., can solve the problems of threshold deformation, difficulty in meeting the electrical safety requirements of new energy vehicles, and the risk of squeezing power battery modules. , to reduce the stiffness, protect the battery, and increase the crumple space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

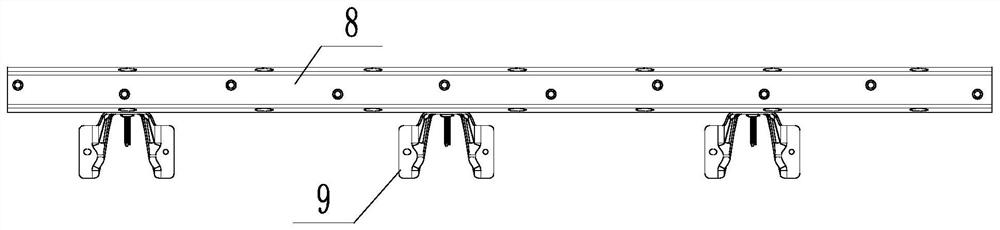

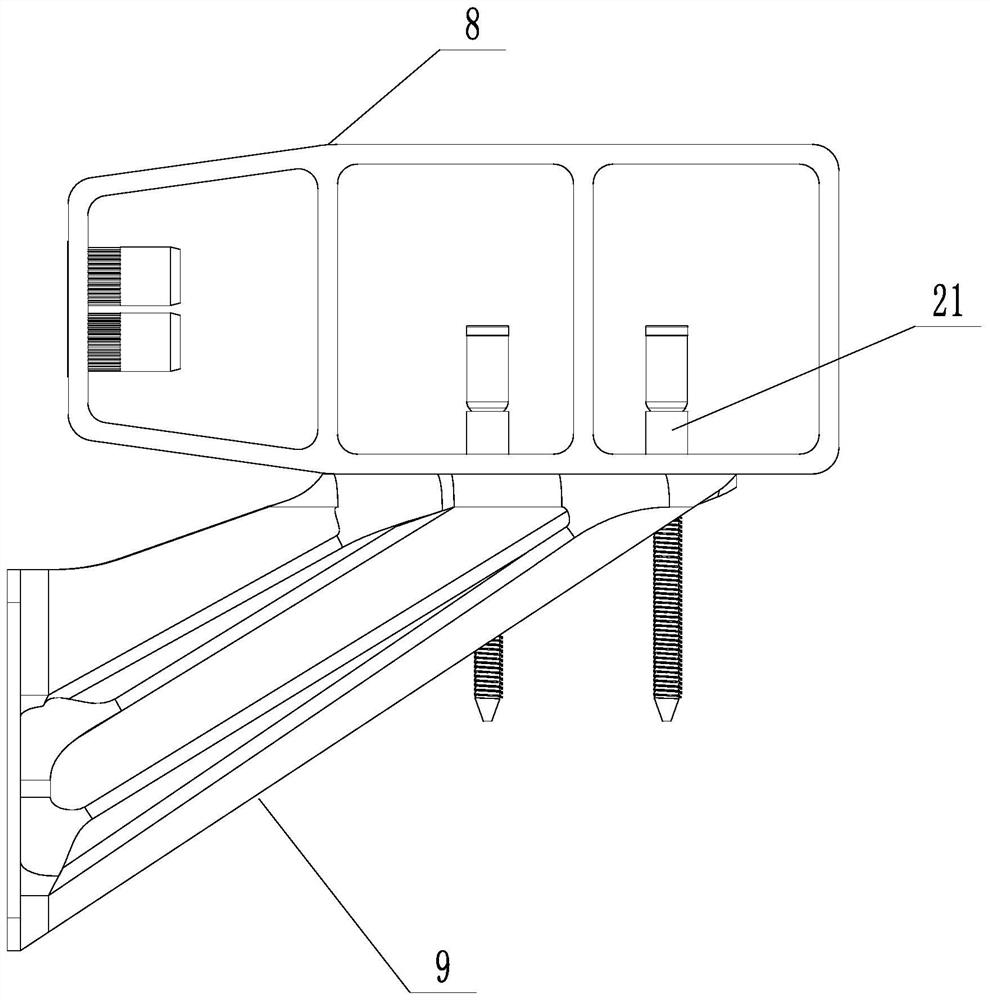

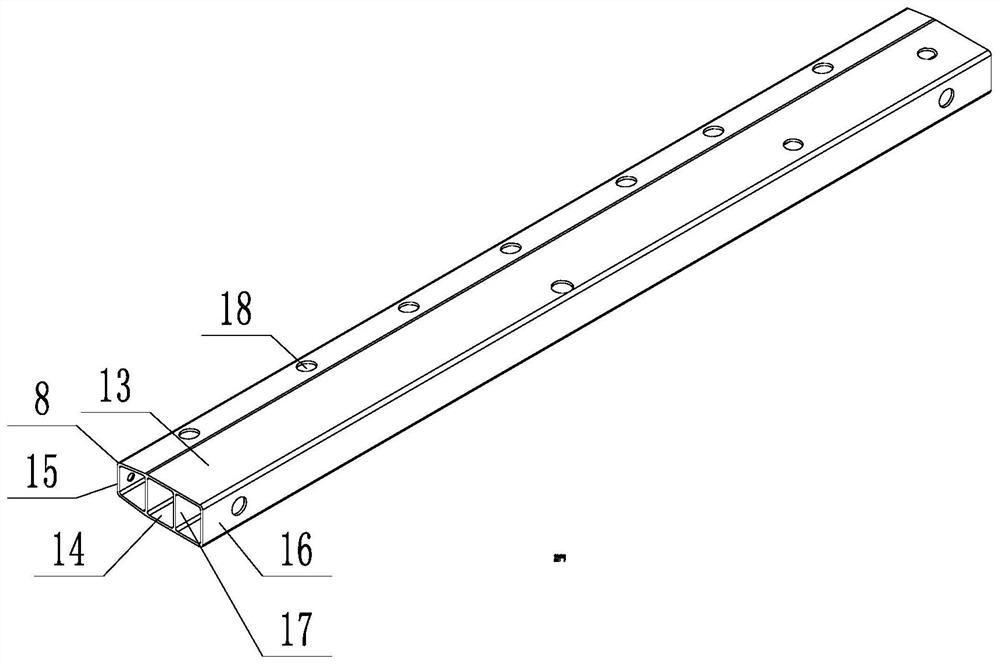

[0031] A new energy vehicle strengthens the threshold, such as Figure 5 As shown, it includes the sill outer panel 1, the sill inner panel 2 and the sill reinforcement structure 3, the sill inner panel 2 is sequentially connected with the seat beam and the reinforcement plate 4 and the power battery module 5 from top to bottom, the sill outer panel 1 and the sill The inner panel 2 forms a hollow cavity 6 . The sides of the door sill inner panel 2 and the door sill outer panel 1 of the automobile are welded and connected together, and the folded parts bulge out from the outside to the inside, forming a so-called hollow cavity 6, the seat beam and the reinforcing plate 4 One end is overlapped and welded on the upper position of the inner panel 2 of the threshold corresponding to the hollow cavity 6 .

[0032]The sill reinforcement structure 3 is arranged in the hollow cavity 6 , the sill reinforcement structure 3 is fixedly connected to the upper and lower parts of the sill ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com