Method for swash suppression of adjustable liquid tank

An adjustable, liquid tank technology, applied in the field of ships and ocean engineering, can solve problems such as pressure rise and component damage safety accidents, and achieve the effects of prolonging life, protecting dampers, and reducing strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

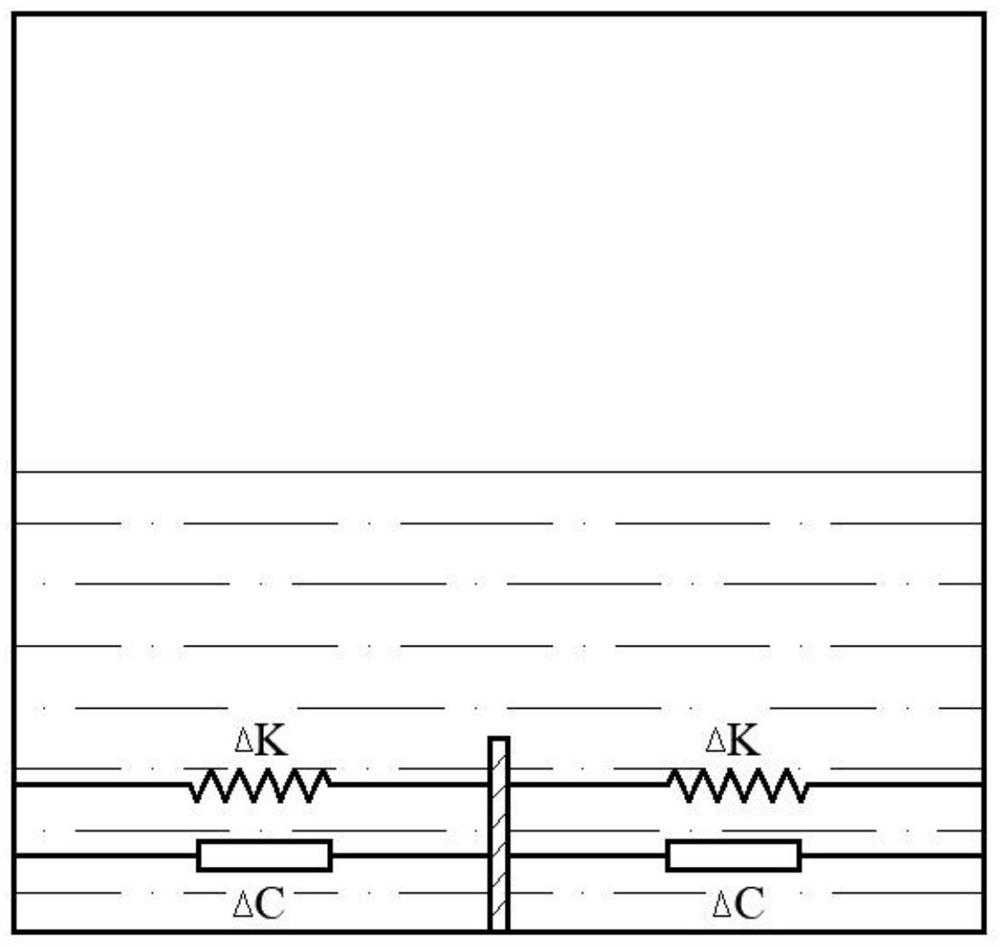

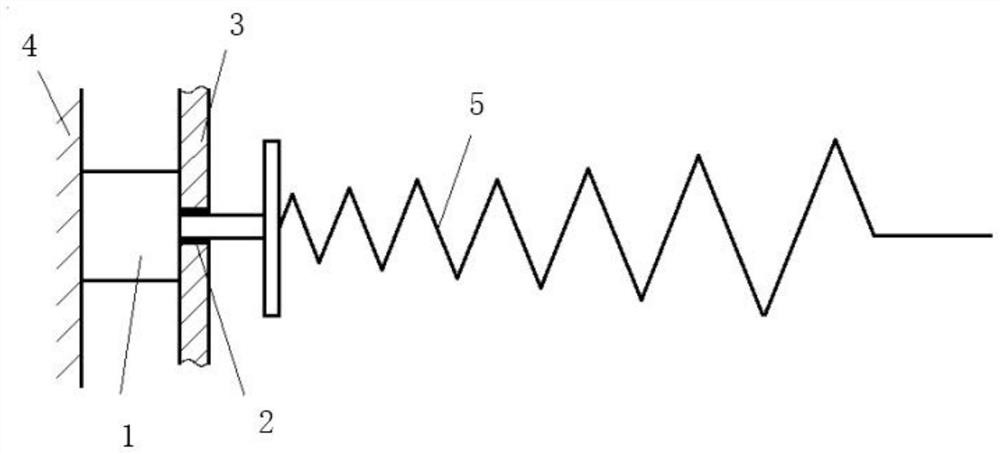

[0020] Example: see Figure 1-3 , the present invention provides a technical solution: a method for adjusting the sloshing of the liquid tank, the specific method is as follows:

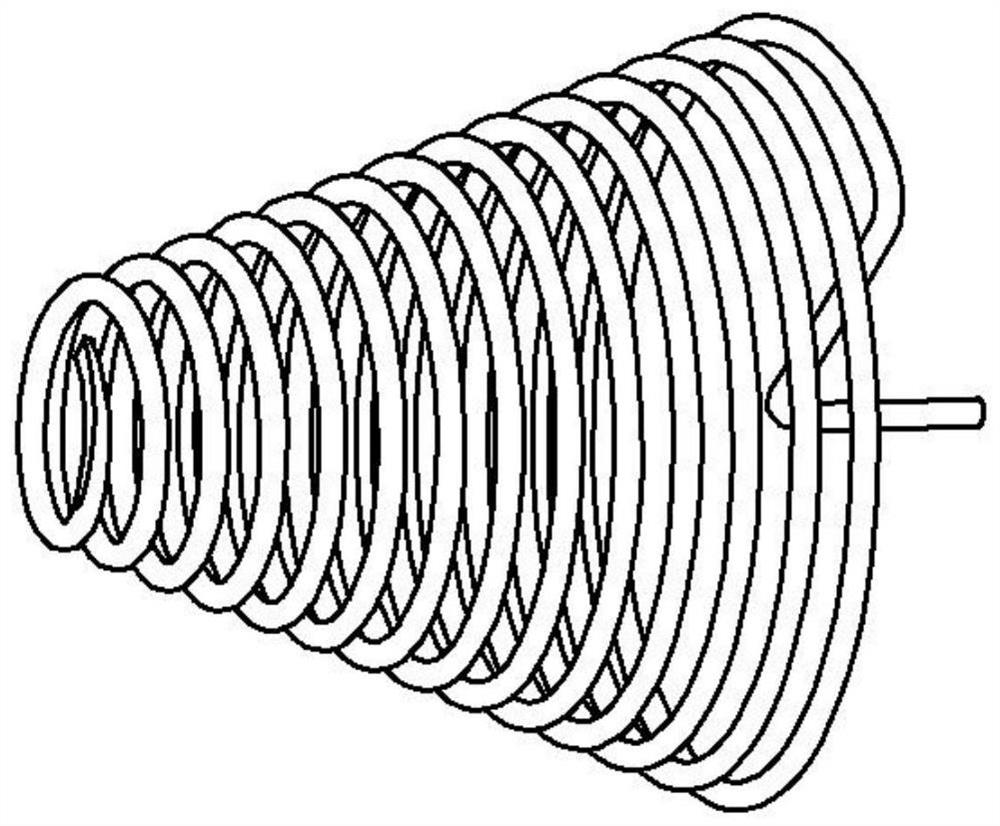

[0021] One or more longitudinal bulkheads distributed intermittently along the length of the tank are arranged at the bottom of the tank, and the lateral movement of the longitudinal bulkhead is realized by connecting with the slide rail along the ship’s width direction, and connected with the bulkhead through springs and dampers, according to For the monitoring of the liquid loading rate of the tank and the external excitation, adjust the parameters of the spring and damper so that the actual resonance frequency of the liquid in the tank is far away from the external excitation frequency during the sloshing process of the tank. Under the joint action of the damper, the energy of liquid sloshing is absorbed and dissipated, thereby reducing the impact pressure on the tank wall as a whole.

[0022] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com