A loading and unloading rotation detection system

A rotating detection and unloading technology, used in rotary conveyors, sorting, conveyor objects, etc., can solve problems such as affecting the accuracy of detection results, requiring extremely high cleanliness, slowing down the detection process, etc., to avoid detection. The effect of data confusion, shortening the detection cycle, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

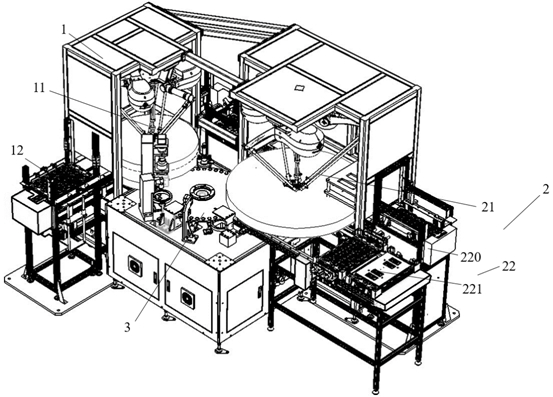

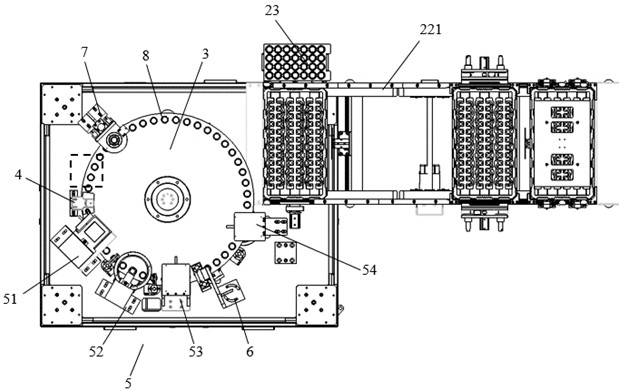

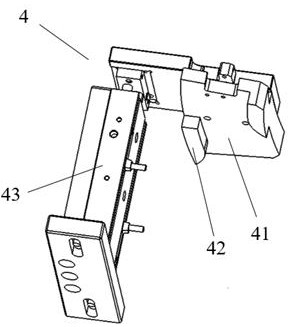

[0039] This embodiment provides a loading and unloading rotation detection system, which can be used to detect at least one kind of workpiece 8 with round edges. Figure 1-9 As shown, the loading and unloading rotation detection system includes a loading mechanism 1, a turntable detection platform, a blanking mechanism 2 and a control mechanism, and the control mechanism can at least be used to control the loading of the loading mechanism 1, the normal rotation of the turntable detection platform and the control mechanism. detection, and the unloading of the unloading mechanism 2, thereby coordinating the operation of the entire system to ensure stable and smooth operation; wherein, the turntable detection platform includes a glass turntable 3, and the feeding mechanism 1 transfers the workpiece 8 to be detected to the glass turntable 3 , for follow-up detection; and, according to the rotation direction of the glass turntable 3, a guiding mechanism 4, two pairs of detection mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com