Positioning structure for gear box assembling

A technology of positioning structure and gearbox, applied in the directions of travel mechanism, transportation and packaging, load hanging components, etc., can solve the problems of easy shaking of the gearbox, damage to the gearbox, and collision and injury, to ensure structural stability, guarantee Stability and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

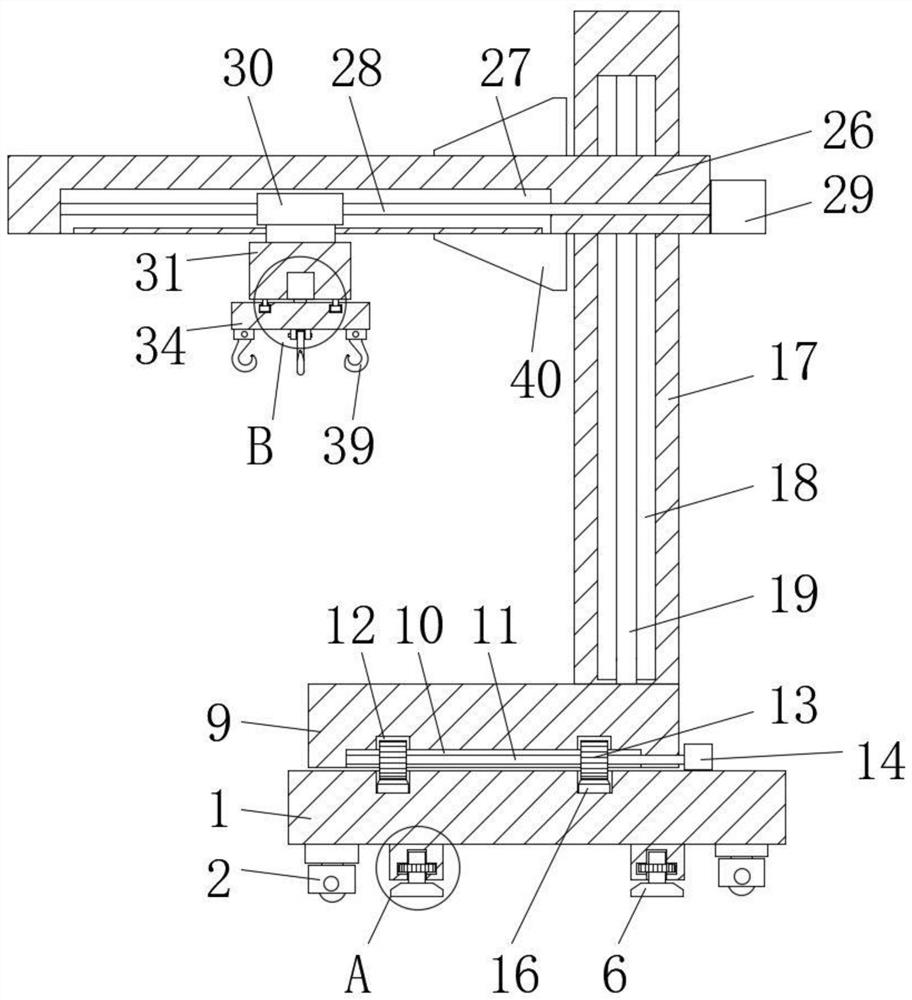

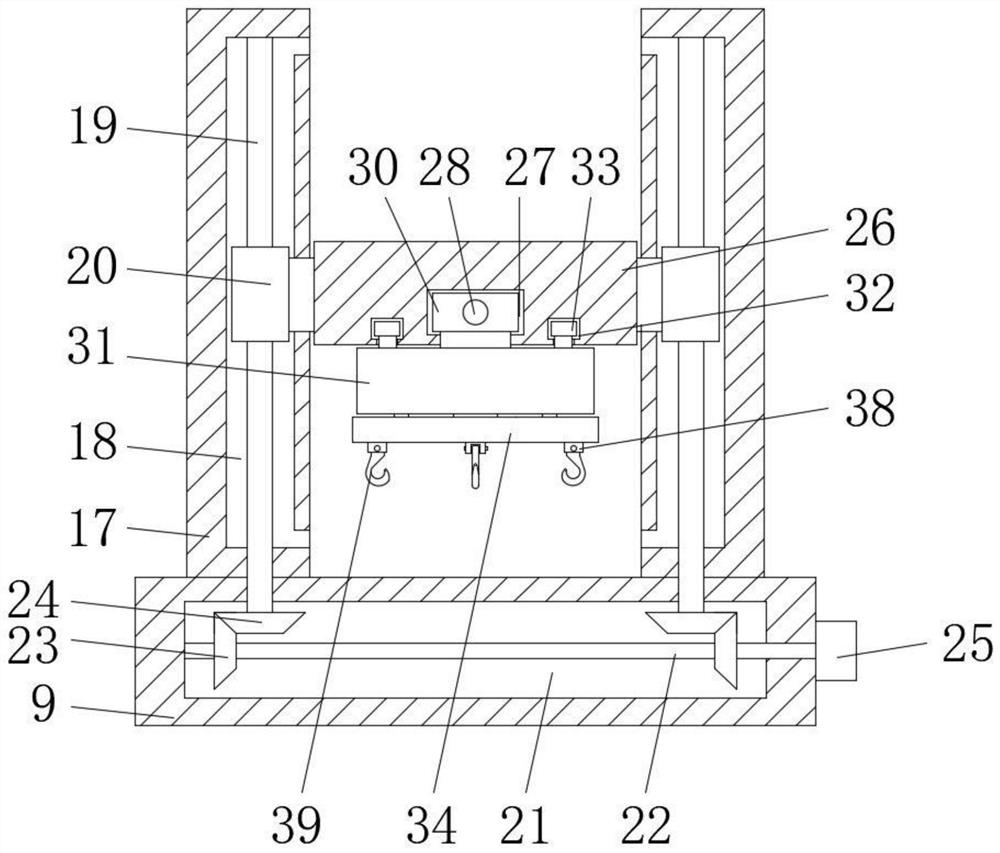

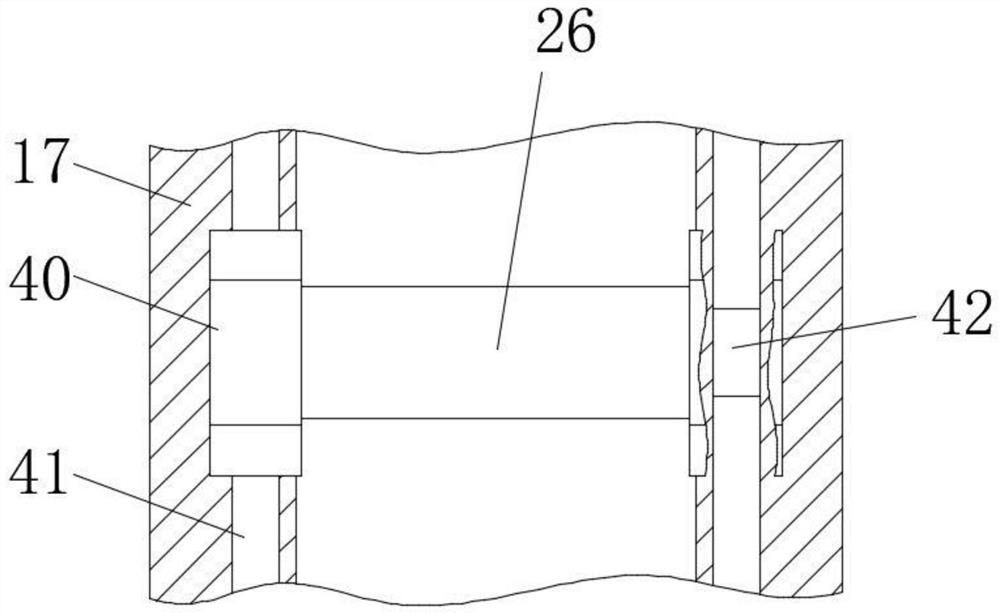

[0028] Such as Figure 1-7As shown, the embodiment of the present invention provides a positioning structure for gear box assembly, including a base 1, the four corners of the bottom of the base 1 are provided with universal wheels 2, and the bottom of the base 1 is located on one side of the four universal wheels 2 The positions are fixedly connected with fixed blocks 3, and the four fixed blocks 3 are all provided with threaded grooves 4, and the insides of the four threaded grooves 4 are all threadedly connected with adjusting screw rods 5, and the bottom ends of the four adjusting screw rods 5 are all provided with support seats 6 The top of the base 1 is provided with a moving seat 9, the bottom of the moving seat 9 is provided with a first groove 10, the first groove 10 is rotatably connected with a first rotating rod 11, and the inner wall of the first groove 10 is provided with two Two notches 12, two notches 12 are provided with a transmission gear 13 that is nested a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com