Additive composition for 3D printing, mortar material and preparation method ofmortar material

A mortar material and 3D printing technology, applied in the field of building materials, can solve the problem that 3D printer materials cannot be used universally, and achieve the effect of wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

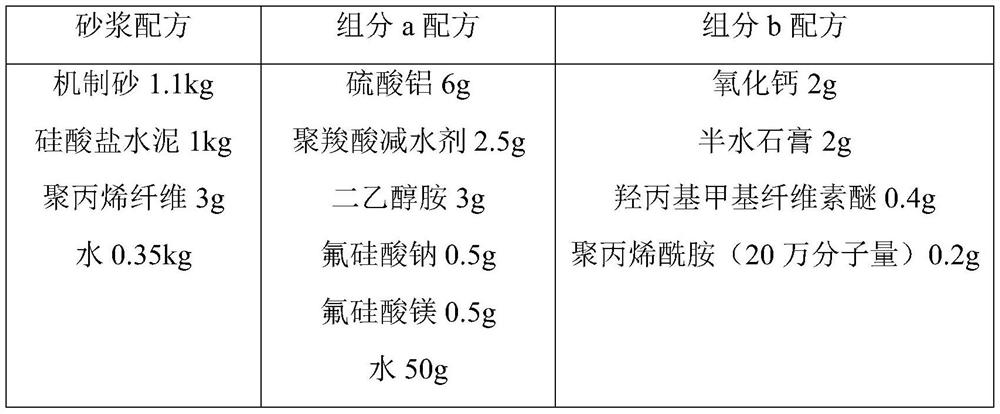

[0071] Example 1

[0072] Preparation of mortar materials using the following preparation method:

[0073] (1) Preparation of components A, steps are as follows:

[0074] Step 1: The water, polycarboxylic acid water water dissipation agent, aluminum sulfate, and dispersant in the component A formulation, stirred at 65 ° C for 30 min until completely dissolved;

[0075] Step 2: Add the alcohollamine compound and a succession, stir for 15 min, cool down to room temperature, to obtain component a.

[0076] (2) Preparation of component B, steps are as follows:

[0077] The components of the component B formulation are mixed in mass.

[0078] (3) Preparation of mortar, steps are as follows:

[0079] Step 1: Mix the gel material, aggregate, and fibers to the component B prepared above to obtain a first mixture;

[0080] Step 2: Mix the above first mixture with water to obtain a second mixture;

[0081] Step 3: Mix the second mixture with the component A prepared above to obtain the mort...

Example

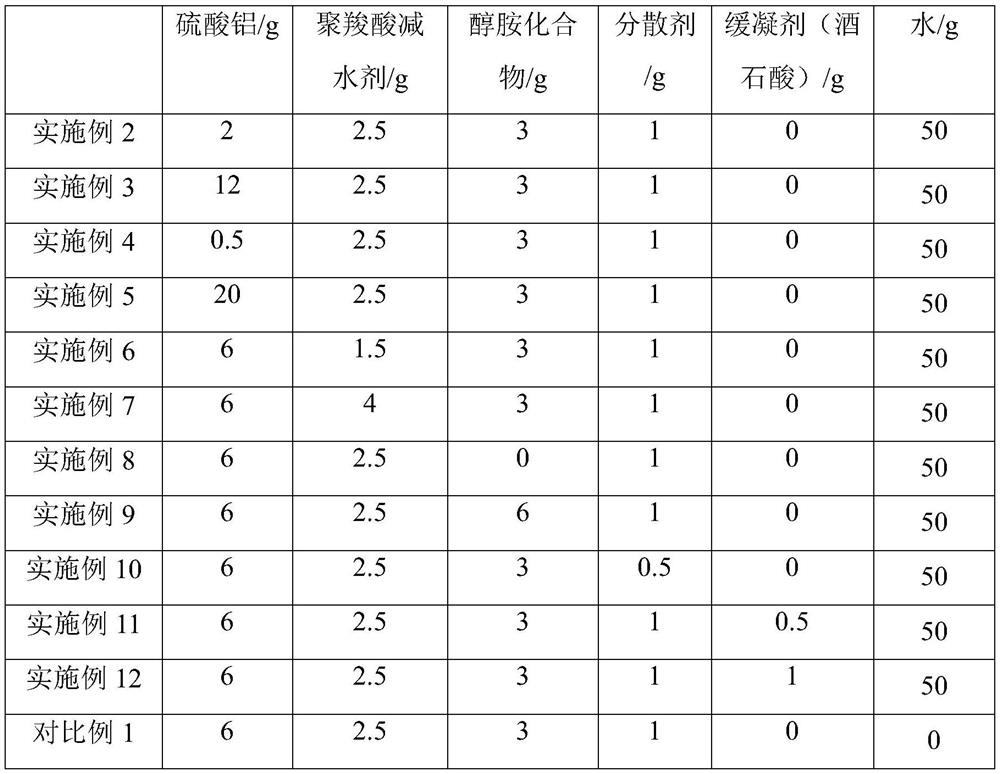

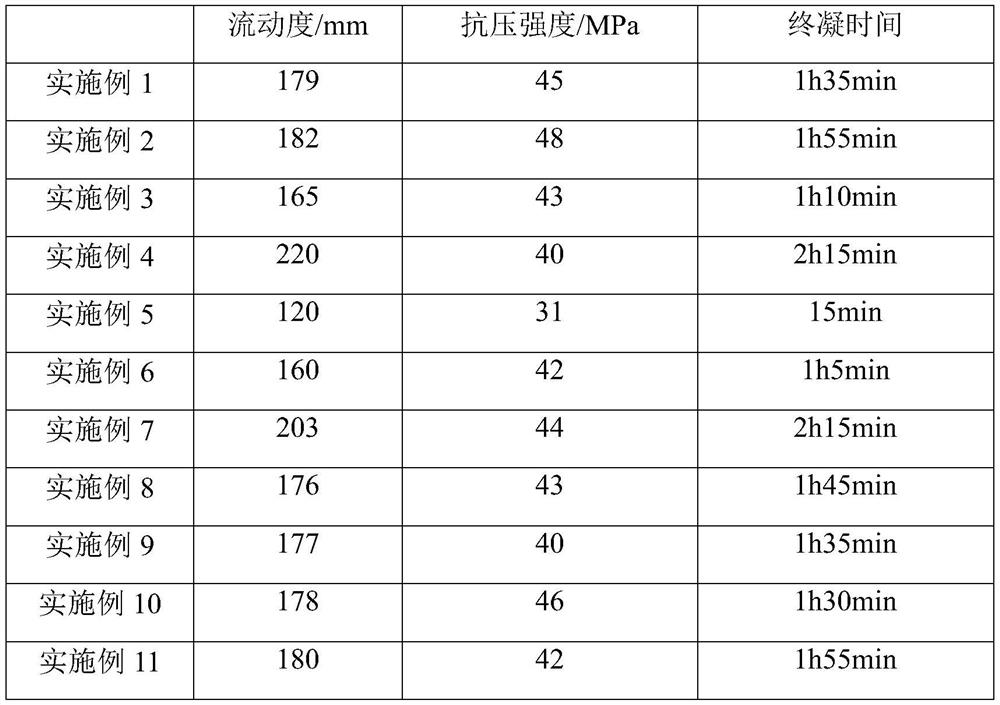

[0086] Example 2 to 12

[0087] The mortar is prepared by the same method as in Example 1, and the difference is only the formulation of component A, as shown in Table 2 below.

[0088] The mortar prepared by Example 2-12 was subjected to mortar flow, 28d compressive strength, and finalization time test, and the test results were shown in Table 3.

Example

[0097] Examples 13 ~ 24

[0098] The mortar was prepared by the same method as in Example 1, and the difference is only the formulation of component B, as shown in Table 4 below.

[0099] The mortar prepared by Examples 13-24 performs mortar flow rate, 28d compressive strength, finalization time test, and the test results are shown in Table 5.

[0100] Table 4

[0101] Calcium oxide / g Gypsum / g Cellulose ether / g Acrylamide polymer / g Example 13 5 2 0.4 0.2 Example 14 10 2 0.4 0.2 Example 15 0.5 2 0.4 0.2 Example 16 20 2 0.4 0.2 Example 17 2 5 0.4 0.2 Example 18 2 10 0.4 0.2 Example 19 2 0.5 0.4 0.2 Example 20 2 20 0.4 0.2 Example 21 2 2 0.01 0.2 Example 22 2 2 2 0.2 Example 23 2 2 0.4 0 Example 24 2 2 0.4 5

[0102] table 5

[0103]

[0104]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com