Self-developed COREX smelting furnace and hydrogen-carbon-rich circulating blast furnace coupled production system

A carbon cycle and hydrogen-rich technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as energy waste and insufficient furnace heat, and achieve the effect of reducing costs, improving quality, and changing production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

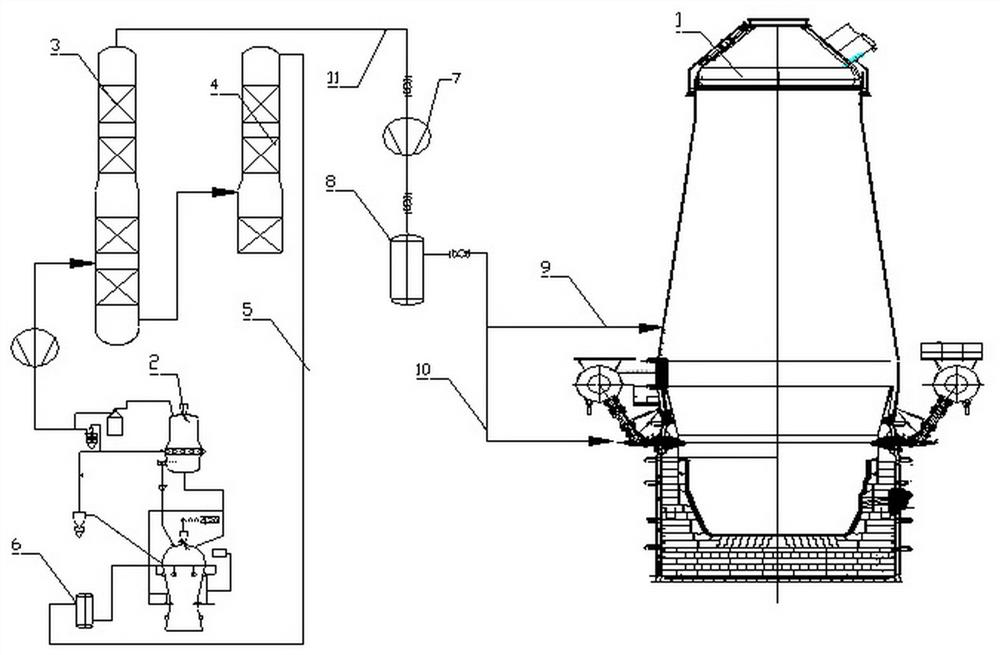

[0011] Embodiments of the present invention are described in detail below, examples of which are shown in the accompanying drawings, and the present invention proposes a production system in which a hydrogen-rich carbon cycle blast furnace is coupled with an Ouyeel furnace.

[0012] Such as figure 1 As shown, the production system coupled with the hydrogen-rich carbon cycle blast furnace and Ouyeel furnace includes: hydrogen-rich carbon cycle blast furnace 1, Ouyeel furnace 2, CO removal 2 Device 3, parsing CO 2 Device 4, CO 2 Pipeline 5 , coal injection system 6 , compressor 7 , heating system 8 , gas pipeline 9 at the lower part of the blast furnace shaft of the hydrogen-rich carbon cycle, tuyere injection pipeline 10 , and reducing gas gas pipeline 11 . Among them, hydrogen-rich carbon cycle blast furnace 1 is used for ironmaking in order to obtain molten iron and produce slag and blast furnace top gas; Ouyeel furnace 2 is also used for ironmaking in order to obtain molte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap